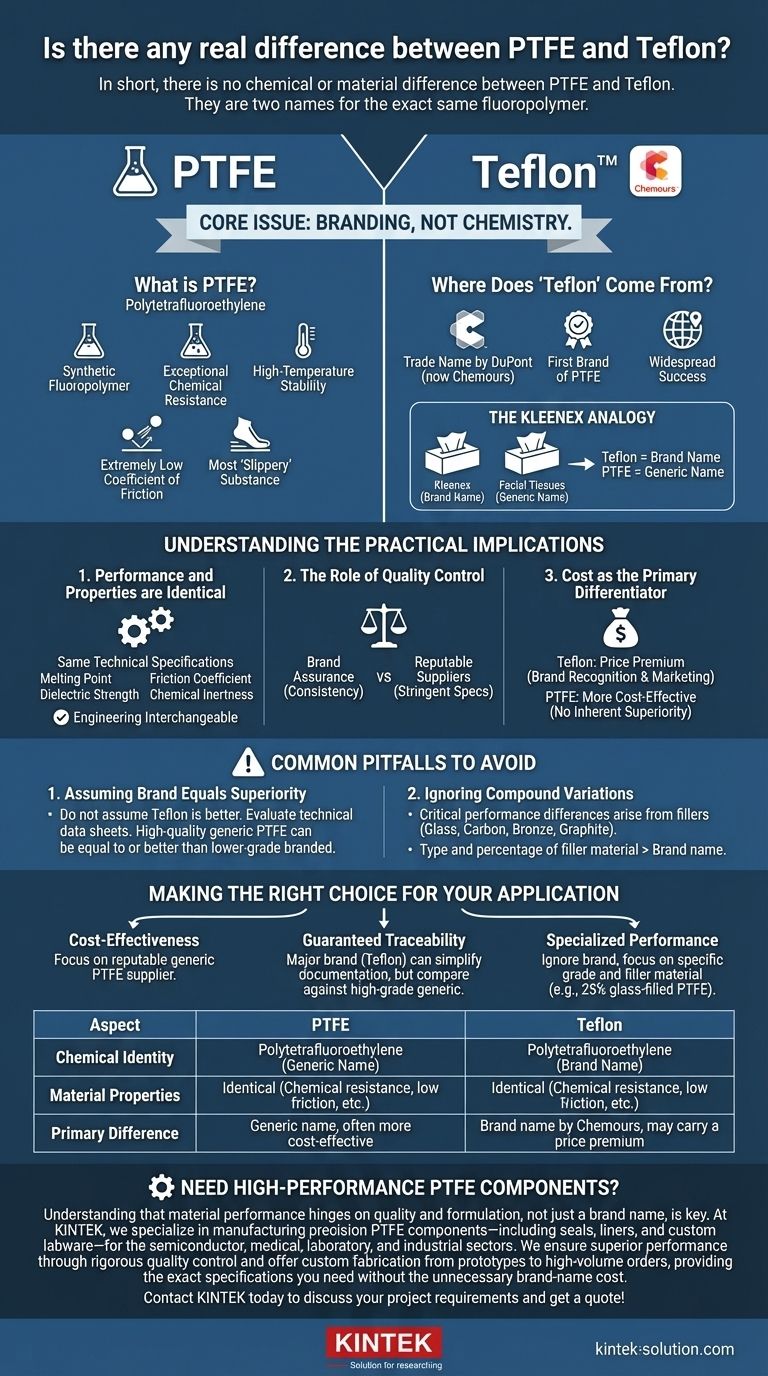

In short, there is no chemical or material difference between PTFE and Teflon. They are two names for the exact same fluoropolymer. PTFE, short for polytetrafluoroethylene, is the generic chemical name, while Teflon is simply the registered trademark and brand name owned by the Chemours company.

The core issue is one of branding, not chemistry. Understanding this distinction allows you to focus on the factors that actually affect performance and cost—such as material grade and supplier quality—rather than a meaningless name debate.

The Name Game: Generic vs. Brand

The confusion between these two terms is a classic case of a brand name becoming synonymous with the product itself. This happens frequently with successful products, but it's critical for technical professionals to understand the underlying reality.

What is PTFE?

PTFE is the acronym for polytetrafluoroethylene. It is a synthetic fluoropolymer known for its remarkable properties, including exceptional chemical resistance, high-temperature stability, and an extremely low coefficient of friction, making it one of the most "slippery" substances known.

Where Does "Teflon" Come From?

Teflon is the trade name that the DuPont company (now Chemours) created to market its PTFE-based products. It was the first brand of PTFE, and its widespread success in consumer and industrial applications caused the name to become a household term.

The Kleenex Analogy

The relationship is identical to that of Kleenex and facial tissues or Band-Aid and adhesive bandages. While you might ask for a "Kleenex," what you are actually seeking is a facial tissue. Teflon is simply the most famous brand name for PTFE.

Understanding the Practical Implications

Because the underlying material is identical, the practical differences are not found in the chemistry but in the marketplace.

Performance and Properties are Identical

A component made from pure, virgin PTFE and one made from pure, virgin Teflon will have the same technical specifications. They share the same melting point, friction coefficient, dielectric strength, and chemical inertness. From an engineering standpoint, they are interchangeable.

The Role of Quality Control

The only potential argument for specifying a brand like Teflon is the assurance of consistent manufacturing and quality control associated with a major corporation. However, numerous reputable suppliers produce high-quality generic PTFE that meets identical or even more stringent specifications.

Cost as the Primary Differentiator

The most significant difference you will likely encounter is price. Products marketed under the Teflon brand name often carry a premium due to brand recognition and marketing costs, not due to any inherent superiority of the material itself.

Common Pitfalls to Avoid

Navigating the sourcing of this material requires looking past the brand name and focusing on what truly matters for your application.

Assuming Brand Equals Superiority

Do not automatically assume a Teflon-branded product is better. Always evaluate materials based on their technical data sheets. A high-quality generic PTFE can perform identically to—or even better than—a lower-grade branded equivalent.

Ignoring Compound Variations

The most critical performance differences arise when PTFE is compounded with fillers. Both generic PTFE and Teflon are often mixed with materials like glass, carbon, bronze, or graphite to enhance properties like wear resistance, creep strength, or thermal conductivity. The type and percentage of this filler material are far more important than the brand name of the base PTFE.

Making the Right Choice for Your Application

Your final decision should be guided by the specific demands of your project, not by branding.

- If your primary focus is cost-effectiveness for a standard application: Sourcing from a reputable generic PTFE supplier is almost always the most logical and economical choice.

- If your primary focus is guaranteed traceability for a critical component: Specifying a major brand like Teflon can sometimes simplify documentation, but be sure to compare its specs against high-grade generic alternatives.

- If your primary focus is specialized performance: Ignore the brand name entirely and concentrate on the specific grade and filler material (e.g., "25% glass-filled PTFE") required to meet your operational demands.

Ultimately, knowing that PTFE and Teflon are chemically identical empowers you to make decisions based on true engineering requirements and value.

Summary Table:

| Aspect | PTFE | Teflon |

|---|---|---|

| Chemical Identity | Polytetrafluoroethylene (Generic Name) | Polytetrafluoroethylene (Brand Name) |

| Material Properties | Identical (Chemical resistance, low friction, etc.) | Identical (Chemical resistance, low friction, etc.) |

| Primary Difference | Generic name, often more cost-effective | Brand name by Chemours, may carry a price premium |

Need High-Performance PTFE Components?

Understanding that material performance hinges on quality and formulation, not just a brand name, is key. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure superior performance through rigorous quality control and offer custom fabrication from prototypes to high-volume orders, providing the exact specifications you need without the unnecessary brand-name cost.

Contact KINTEL today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments