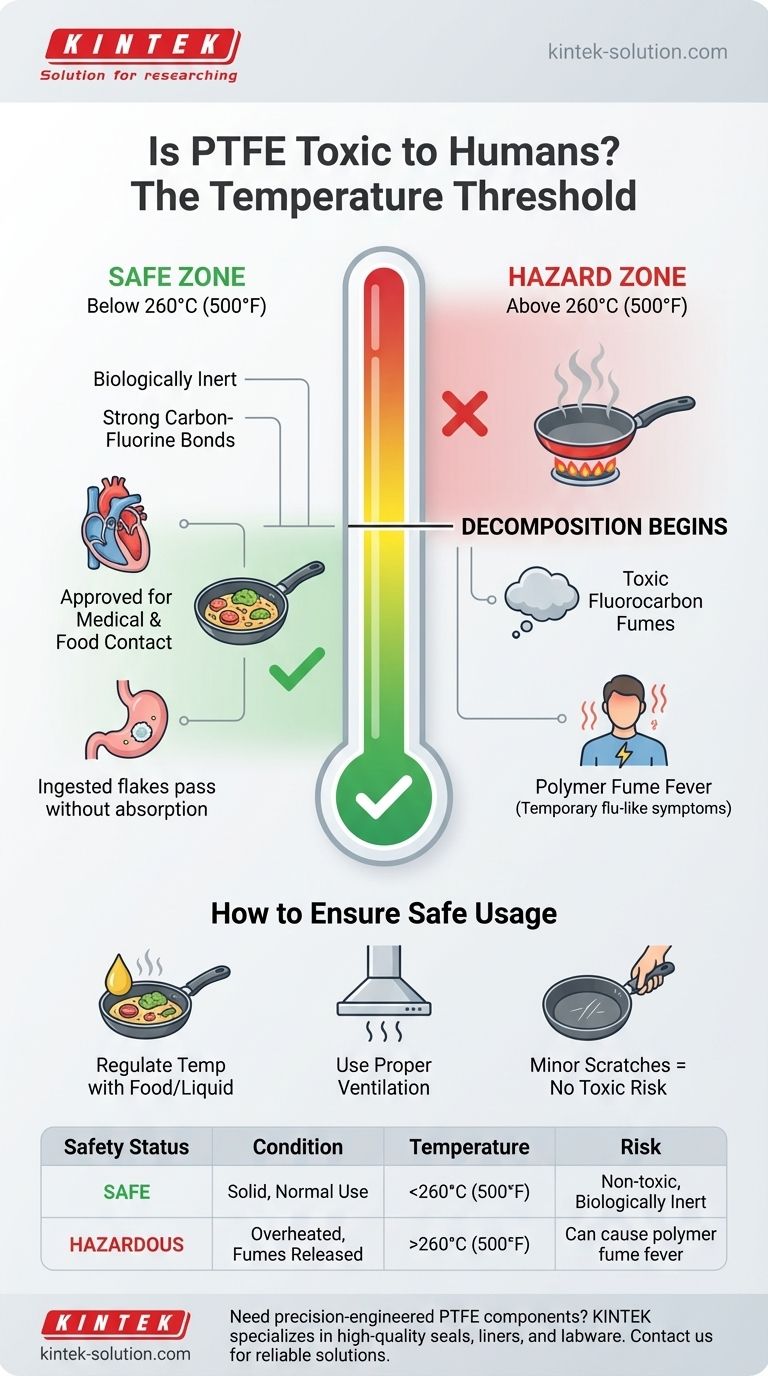

In its solid form, PTFE is considered non-toxic and biologically inert. The material is exceptionally stable and safe for human contact, which is why it's widely used in everything from medical implants to non-stick cookware. The safety profile changes significantly only when PTFE is heated to extreme temperatures, above 260°C (500°F), at which point it can release harmful fumes.

The question of PTFE's toxicity is fundamentally about temperature. The risk is not from the material itself under normal conditions, but from the fumes created when it is severely overheated—a situation that is entirely avoidable through proper use.

Understanding PTFE's Chemical Stability

Why PTFE is Generally Safe

Polytetrafluoroethylene (PTFE) is a fluoropolymer with incredibly strong carbon-fluorine bonds. These bonds make the material highly stable and resistant to chemical reactions.

This inert nature means PTFE does not react with chemicals inside the human body, which is why it is approved for use in medical devices and food processing equipment.

The Myth of Scratches and Flakes

A common concern is the ingestion of small flakes from scratched PTFE-coated cookware. Because the material is biologically inert, these small particles are non-toxic.

If accidentally ingested, solid PTFE flakes will simply pass through the digestive system without being absorbed, posing no chemical threat to the body.

The Point of Decomposition: When the Hazard Emerges

The Critical Temperature Threshold

The safety of PTFE is compromised only when it is subjected to extreme heat. The decomposition process begins around 260°C (500°F) and accelerates at higher temperatures.

It is crucial to understand that these temperatures are well above those used for most normal cooking tasks like boiling (100°C / 212°F) or frying (175-230°C / 350-450°F).

The Risk of Toxic Fumes

When PTFE overheats, its stable bonds break down, releasing various toxic fluorocarbon fumes.

Inhaling these fumes can lead to a temporary, flu-like condition known as polymer fume fever. Symptoms include chills, fever, headache, and body aches, which typically resolve within 24-48 hours.

Common Pitfalls and Real-World Scenarios

The Unattended Empty Pan

The most common scenario for overheating PTFE occurs when an empty non-stick pan is left on a high-heat burner. Without food to absorb the energy, the pan's temperature can rise rapidly past the safe threshold.

The Importance of Ventilation

Using proper ventilation, such as a range hood, is a fundamental safety practice in any kitchen. It helps dissipate any fumes, whether from burning food or, in a rare case, an overheated pan.

Industrial vs. Consumer Risks

While consumer risk is low and manageable, industrial settings that involve heating PTFE for manufacturing require strict temperature controls and robust ventilation systems to protect workers from fume exposure.

How to Ensure Safe Usage

Following a few simple principles ensures that PTFE-coated products remain safe for their entire lifespan.

- If your primary focus is daily cooking: Never preheat an empty pan on high heat and avoid leaving cookware unattended on an active burner.

- If you are concerned about damaged cookware: Understand that minor scratches do not pose a toxicological risk, though they may reduce the pan's non-stick performance.

- If you use high-heat cooking methods: Always ensure there is oil, water, or food in the pan to regulate the temperature and prevent it from exceeding safe limits.

Ultimately, managing temperature is the key to using PTFE products safely and effectively.

Summary Table:

| Safety Status | Condition | Temperature | Risk |

|---|---|---|---|

| Safe | Solid, Normal Use | Below 260°C (500°F) | Non-toxic, biologically inert |

| Hazardous | Overheated, Fumes Released | Above 260°C (500°F) | Can cause polymer fume fever |

Need precision-engineered PTFE components you can trust?

At KINTEK, we specialize in manufacturing high-quality PTFE seals, liners, and labware for the semiconductor, medical, and laboratory industries. Our components are produced with precision and strict quality control to ensure performance and safety, even in demanding applications. Whether you need custom prototypes or high-volume orders, we deliver reliable solutions.

Contact us today to discuss your specific requirements and learn how our PTFE expertise can benefit your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments