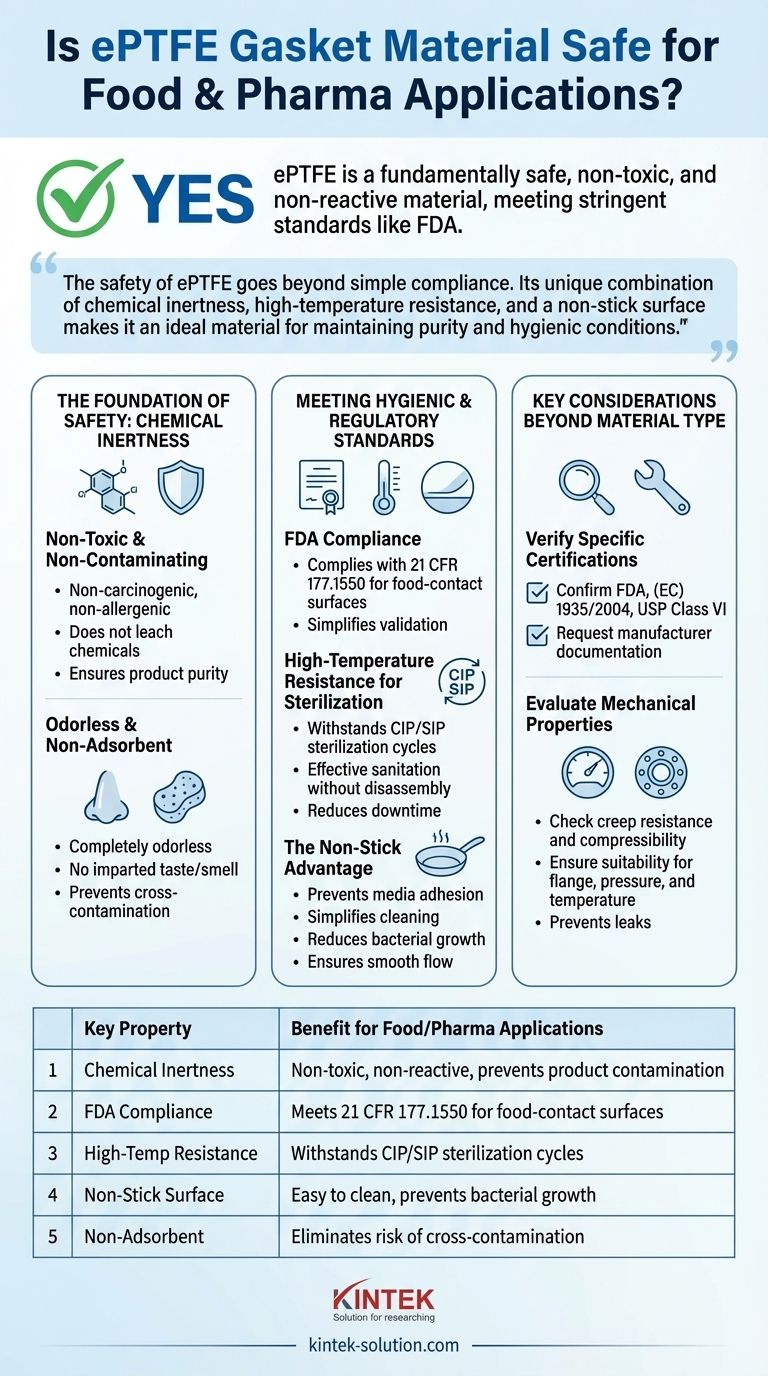

Yes, expanded Polytetrafluoroethylene (ePTFE) is a fundamentally safe material for food and pharmaceutical applications. Its inherent chemical properties make it non-toxic and non-reactive, and it meets the stringent regulatory standards required for these sensitive industries, such as those set by the FDA. This ensures that the gasket will not contaminate the product it comes into contact with.

The safety of ePTFE goes beyond simple compliance. Its unique combination of chemical inertness, high-temperature resistance, and a non-stick surface makes it an ideal material for maintaining the purity and hygienic conditions essential in food and pharmaceutical processing.

The Foundation of Safety: Chemical Inertness

The primary reason ePTFE is trusted in sensitive applications is that it is one of the most chemically inert materials known. This core property is the source of its safety and reliability.

Non-Toxic and Non-Contaminating

ePTFE is inherently non-toxic, non-carcinogenic, and non-allergenic. It does not leach chemicals or contaminants into the process media.

This ensures the final product—whether a medication or a food item—remains pure and unadulterated, a critical requirement for consumer safety.

Odorless and Non-Adsorbent

The material is completely odorless and will not impart any taste or smell to the products it seals.

Furthermore, ePTFE does not adsorb or absorb the media it contains. This prevents cross-contamination between different batches and ensures product integrity.

Meeting Hygienic and Regulatory Standards

Beyond its chemical makeup, ePTFE possesses physical properties that make it uniquely suited for environments where cleanliness and regulatory adherence are non-negotiable.

FDA Compliance

Reputable ePTFE gasketing materials are manufactured to comply with FDA regulations (specifically 21 CFR 177.1550) for food-contact surfaces.

This compliance provides documented assurance that the material is safe for its intended use, simplifying validation processes for manufacturers.

High-Temperature Resistance for Sterilization

ePTFE can withstand the high temperatures required for sterilization processes like Clean-in-Place (CIP) and Sterilization-in-Place (SIP).

This allows equipment to be sanitized effectively without needing to remove the gaskets, reducing downtime and ensuring a consistently hygienic environment.

The Non-Stick Advantage

The famous non-stick surface of PTFE prevents process media from adhering to the gasket. This quality is crucial for hygiene.

It simplifies cleaning, reduces the potential for bacterial growth, and ensures a smooth, non-disruptive flow of materials within the system.

Key Considerations Beyond Material Type

While ePTFE is an excellent choice, selecting the right gasket requires looking beyond the material name alone. True operational safety lies in the details of the specific product and its application.

Verify Specific Certifications

Always confirm that the specific ePTFE product you are purchasing comes with the necessary certifications for your industry, such as FDA, (EC) 1935/2004, or USP Class VI.

Do not assume all ePTFE gaskets are certified. Request documentation from the manufacturer or supplier to ensure full compliance.

Evaluate Mechanical Properties

Different ePTFE gaskets have different mechanical properties, such as creep resistance and compressibility, which can affect sealing performance.

Ensure the gasket is appropriate for your specific flange type, pressure, and temperature conditions to prevent leaks. A material that is safe but fails to seal properly still represents an operational risk.

Making the Right Choice for Your Goal

Selecting the correct gasket depends on prioritizing the most critical factor for your specific process.

- If your primary focus is absolute purity: Choose an ePTFE gasket with documented non-adsorbent properties to prevent any possibility of cross-contamination.

- If your primary focus is guaranteed regulatory compliance: Demand gaskets that come with explicit FDA and/or USP Class VI certifications from the manufacturer.

- If your primary focus is operational hygiene and cleanability: Prioritize ePTFE for its non-stick surface and proven resistance to CIP/SIP chemical and thermal cycles.

Ultimately, choosing a certified ePTFE gasket is a reliable way to ensure safety, compliance, and purity in your critical processes.

Summary Table:

| Key Property | Benefit for Food/Pharma Applications |

|---|---|

| Chemical Inertness | Non-toxic, non-reactive, prevents product contamination |

| FDA Compliance | Meets 21 CFR 177.1550 for food-contact surfaces |

| High-Temp Resistance | Withstands CIP/SIP sterilization cycles |

| Non-Stick Surface | Easy to clean, prevents bacterial growth |

| Non-Adsorbent | Eliminates risk of cross-contamination |

Ensure the purity and compliance of your critical processes with KINTEK's precision ePTFE gaskets.

We specialize in manufacturing high-performance PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our ePTFE gaskets are engineered to meet the stringent demands of food and pharmaceutical applications, offering guaranteed FDA compliance, superior chemical resistance, and reliable sealing performance.

Partner with KINTEK for:

- Certified Materials: Ensure your gaskets meet FDA, USP Class VI, and other relevant standards.

- Custom Fabrication: Get the exact fit and performance you need, from prototypes to high-volume orders.

- Uncompromising Quality: Benefit from our focus on precision production and material integrity.

Contact us today to discuss your specific application requirements and receive a quote: Get in Touch

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications