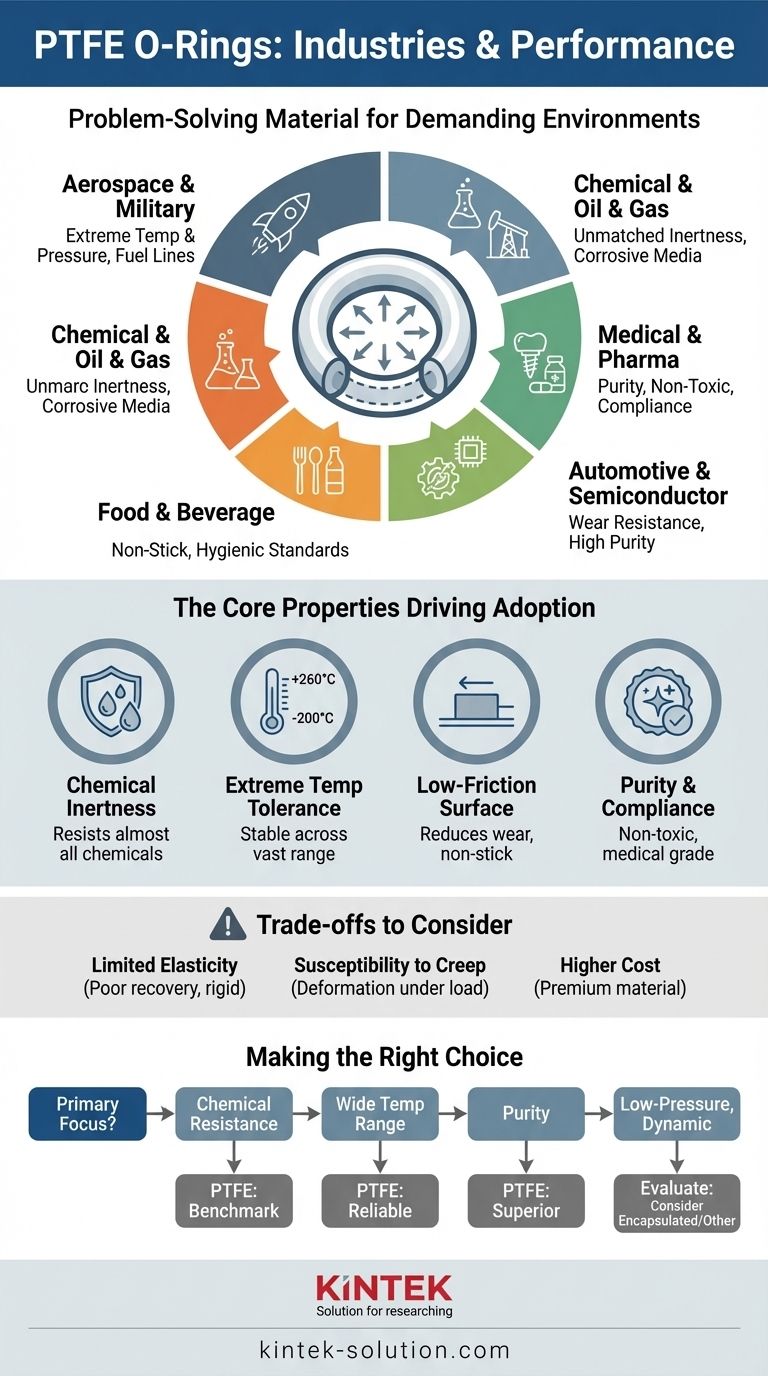

In short, PTFE O-rings are commonly used in the most demanding industries, including aerospace, chemical processing, oil & gas, medical, and pharmaceutical. Their adoption is driven by an exceptional ability to perform reliably under extreme conditions where conventional elastomers would fail, such as exposure to corrosive chemicals, high pressures, and extreme temperatures.

The critical takeaway is not just which industries use PTFE O-rings, but why. PTFE is a problem-solving material, selected specifically for applications where performance and reliability in harsh environments are non-negotiable.

The Core Properties Driving PTFE Adoption

The widespread use of PTFE O-rings across various sectors is not accidental. It is a direct result of a unique combination of material properties that make it uniquely suited for severe service applications.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, solvents, and corrosive agents. This makes it an essential sealing material in environments like chemical manufacturing plants and oil and gas exploration, where seals are constantly exposed to aggressive substances.

Extreme Temperature Tolerance

PTFE O-rings maintain their integrity and sealing capability across a vast temperature range. This stability is critical for applications in the aerospace and automotive industries, from engine components to systems exposed to the vacuum and temperature fluctuations of space.

Low-Friction and Non-Stick Surface

The material's inherently low coefficient of friction (one of the lowest of any solid) and non-stick properties are highly valuable. This reduces wear in dynamic applications like pumps and valves and prevents contamination in the food, beverage, and pharmaceutical industries.

Purity and Compliance

PTFE is non-toxic and can comply with strict regulatory standards for sanitary applications. This makes it a default choice for medical devices, implants, fluid handling systems, and food processing equipment where purity is paramount.

Key Industry Applications in Detail

Understanding the core properties allows us to see exactly how PTFE solves specific problems within each major industry.

Aerospace and Military

In this sector, failure is not an option. PTFE seals are used in hydraulic systems, fuel lines, and engines because they can withstand extreme pressure, aggressive fuels, and wide temperature swings encountered during flight.

Chemical Processing and Oil & Gas

These industries rely on PTFE for seals in pumps, valves, and reactors. The material's resistance to corrosive chemicals and high-pressure, high-temperature (HPHT) conditions prevents leaks and ensures operational safety.

Medical and Pharmaceutical

The inertness and non-toxic nature of PTFE are crucial for medical fluid systems, processing equipment, and even implants. It ensures that the seal itself does not contaminate or react with the sensitive materials it contacts.

Food and Beverage

PTFE's non-stick surface and compliance with food-grade standards make it ideal for sealing processing equipment. It resists degradation from harsh cleaning chemicals and prevents product buildup, ensuring a hygienic environment.

Automotive and Semiconductor

In the automotive industry, PTFE is used for seals and rings in engines and transmissions that require high wear resistance and temperature stability. In semiconductor manufacturing, its purity and chemical resistance are vital for tools used in fabrication processes.

Understanding the Trade-offs

While its performance is exceptional, PTFE is not a universal solution. An objective technical assessment requires acknowledging its limitations.

Limited Elasticity

Compared to rubber elastomers like Viton or EPDM, pure PTFE is a relatively rigid material. It has poor "elastic memory," meaning it does not spring back to its original shape as effectively after being compressed. This must be accounted for in the gland design.

Susceptibility to Creep

Under a constant compressive load, especially at elevated temperatures, PTFE can slowly deform over time, a phenomenon known as "creep." This can lead to a loss of sealing force if not managed through proper engineering and joint design.

Higher Cost

PTFE is a premium performance material, and its cost reflects that. While it provides immense value in critical applications, it may be overkill for simple, low-stress environments where a standard elastomer would suffice.

Making the Right Choice for Your Goal

Selecting the right sealing material depends entirely on the demands of your specific application.

- If your primary focus is chemical resistance: PTFE is the industry benchmark for sealing against the most aggressive and corrosive media.

- If your primary focus is a wide temperature range: PTFE provides reliable sealing in environments far too hot or cold for most conventional elastomers.

- If your primary focus is purity and non-contamination: PTFE's inertness makes it the superior choice for medical, pharmaceutical, and food-grade applications.

- If your primary focus is a low-pressure, dynamic seal: Carefully evaluate PTFE's limited elasticity; an encapsulated O-ring or a different elastomer may be a better fit.

Ultimately, PTFE O-rings are chosen not for the industry they serve, but for the extreme operational challenges they solve within it.

Summary Table:

| Industry | Key Application | Why PTFE is Chosen |

|---|---|---|

| Aerospace & Military | Hydraulic systems, fuel lines, engines | Extreme temperature & pressure resistance |

| Chemical Processing & Oil & Gas | Pumps, valves, reactors | Unmatched chemical inertness for corrosive media |

| Medical & Pharmaceutical | Medical devices, fluid systems, implants | Purity, non-toxicity, and regulatory compliance |

| Food & Beverage | Processing equipment | Non-stick surface and food-grade standards |

| Semiconductor & Automotive | Fabrication tools, engine components | High purity, wear resistance, and temperature stability |

Need a PTFE sealing solution for your demanding application?

KINTEK specializes in manufacturing high-performance PTFE components, including O-rings, seals, liners, and custom labware. We serve the semiconductor, medical, laboratory, and industrial sectors by prioritizing precision and offering custom fabrication from prototypes to high-volume orders.

Let us help you solve your most extreme sealing challenges. Contact KINTEK today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance