At its core, Polytetrafluoroethylene (PTFE) is the material of choice for sealing applications where standard materials would fail. PTFE oil seals are commonly specified for demanding environments such as high-performance automotive engines, aerospace hydraulic systems, chemical processing pumps, and heavy industrial gearboxes. Their use is defined by a need for reliability under extreme temperature, pressure, or chemical exposure.

The decision to use a PTFE oil seal is driven by extreme operating conditions. While common elastomeric seals are sufficient for many jobs, PTFE is specified when an application involves high temperatures, high rotational speeds, aggressive chemicals, or a need for very low friction and long service life.

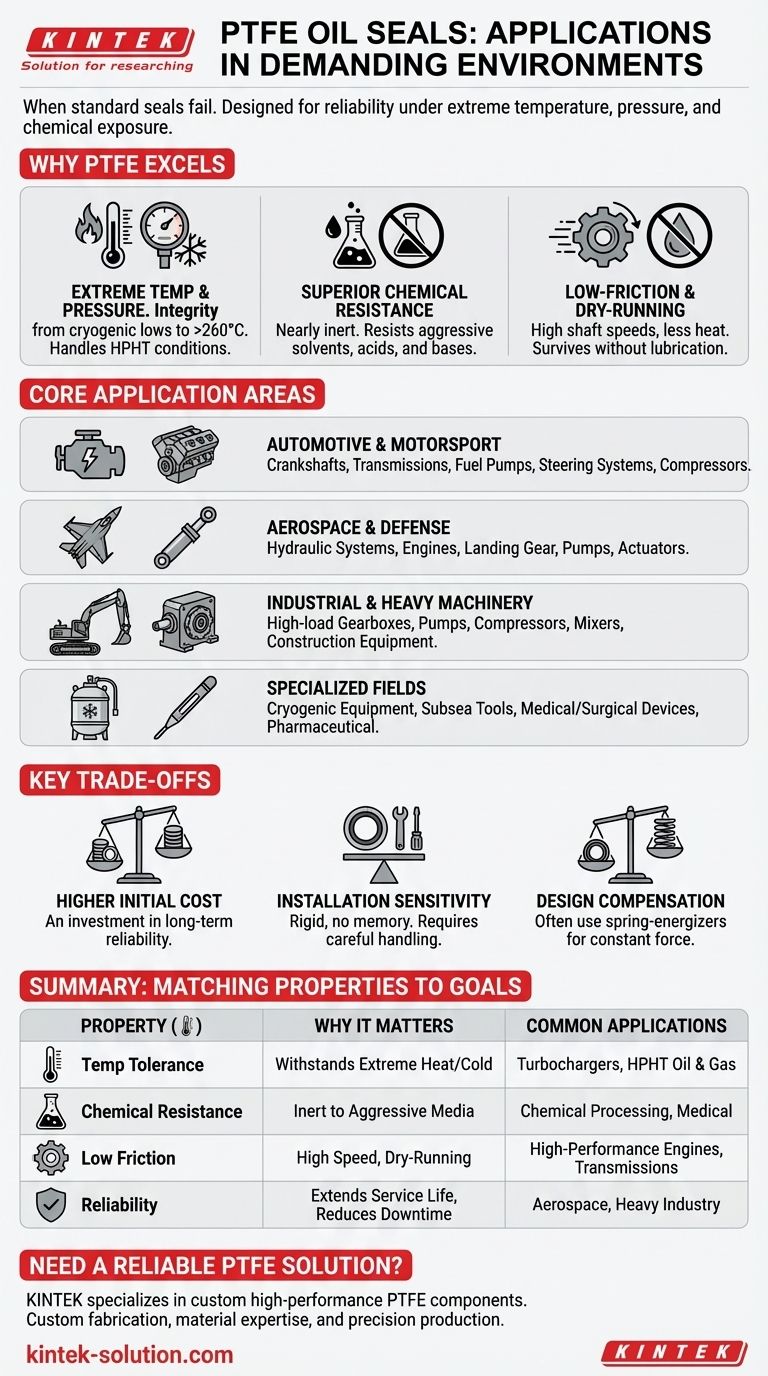

Why PTFE Excels in Demanding Environments

To understand where PTFE seals are used, you must first understand why they are chosen over more common and less expensive elastomeric (rubber) seals. The selection is almost always a response to an operational challenge that rubber cannot handle.

Extreme Temperature and Pressure Tolerance

PTFE maintains its integrity across an exceptionally wide temperature range, from cryogenic lows to highs exceeding what any standard rubber can withstand.

This makes it essential for applications like turbochargers, high-performance engines, and equipment in the petroleum industry operating in high-pressure, high-temperature (HPHT) conditions.

Superior Chemical Resistance

PTFE is nearly chemically inert. It resists degradation from the aggressive solvents, acids, and bases found in chemical processing equipment.

This property also makes it ideal for the food, pharmaceutical, and medical industries, where seals must not react with the product and must withstand harsh cleaning and sterilization cycles in equipment like autoclaves and hematology analyzers.

Low-Friction and Dry-Running Capability

PTFE has an extremely low coefficient of friction. This unique characteristic allows PTFE seals to run at high shaft speeds with less heat generation and wear.

Crucially, it also enables them to survive "dry running"—periods of operation with little to no lubrication—without catastrophic failure, a condition that would quickly destroy an elastomeric seal.

Core Application Areas

Based on these properties, PTFE seals are found in a wide array of critical systems across multiple industries.

Automotive and Motorsport

The automotive sector relies on PTFE for high-performance and long-life applications where standard seals would quickly degrade.

Common uses include engine crankshaft seals, transmissions, fuel injection pumps, steering systems, and air conditioning compressors.

Aerospace and Defense

Reliability is non-negotiable in aerospace, making PTFE a default choice for many systems.

It is used extensively in aircraft hydraulic systems, engines, landing gear brakes, and pumps where temperature fluctuation and high pressure are constant factors.

Industrial and Heavy Machinery

In industrial settings, PTFE seals increase service life and reduce downtime in critical machinery.

They are found in high-load gearboxes, pumps, compressors, mixers, blowers, and construction machinery like excavators and loaders, where they resist wear from abrasive media.

Specialized Fields

PTFE's unique combination of properties makes it a problem-solver in several specialized domains.

This includes cryogenic equipment, subsea oil and gas tools, and biocompatible seals for surgical tools and medical devices.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. Its unique characteristics introduce specific trade-offs that must be managed.

Higher Initial Cost

PTFE is a premium material, and seals made from it are more expensive than their common elastomeric counterparts. Their use is an investment in reliability and extended service life, justified by the cost of failure or downtime.

Installation Sensitivity

PTFE is a rigid plastic, not a flexible rubber. It has no "elastic memory," meaning it will not snap back into shape if stretched or deformed. This makes installation more delicate and often requires specialized tools to prevent damage to the sealing lip.

Designs Compensate for Rigidity

Because PTFE is not naturally elastic, many PTFE seal designs incorporate a spring-energizer. This is a small metal spring embedded in the seal that provides the constant radial force needed to maintain contact with the shaft, a function that rubber performs naturally.

Making the Right Choice for Your Goal

The decision to use a PTFE seal should be based on a clear understanding of your application's specific demands.

- If your primary focus is high-speed rotation or potential dry running: PTFE's low-friction properties prevent heat buildup and wear where elastomers would quickly fail.

- If your application involves aggressive chemicals or extreme temperatures: PTFE's chemical inertness and wide temperature range make it the most reliable choice.

- If your goal is maximum reliability and service life in a critical system: The durability and wear resistance of filled or spring-energized PTFE seals justify their use in demanding engines, gearboxes, and pumps.

- If you are working with a standard, low-cost application with moderate conditions: A traditional elastomeric (Nitrile or FKM/Viton®) seal is often the more practical and cost-effective solution.

Choosing the right seal is about matching the material's capabilities to the precise demands of the application.

Summary Table:

| Key Property | Why It Matters | Common Applications |

|---|---|---|

| Extreme Temperature Tolerance | Withstands cryogenic to high heat (>260°C) | Turbochargers, HPHT oil & gas equipment |

| Superior Chemical Resistance | Inert to aggressive acids, bases, solvents | Chemical processing pumps, medical devices |

| Low Friction & Dry-Running | Operates at high speeds with minimal lubrication | High-performance engines, transmissions, compressors |

| Long Service Life & Reliability | Reduces downtime in critical systems | Aerospace hydraulics, industrial gearboxes, heavy machinery |

Need a Reliable PTFE Seal Solution for Your Demanding Application?

If your operations involve high temperatures, aggressive chemicals, high speeds, or a critical need for reliability, a standard seal may not be enough. KINTEK specializes in the precision manufacturing of high-performance PTFE components—including seals, liners, and custom labware.

We serve the semiconductor, medical, laboratory, and industrial sectors by providing:

- Custom Fabrication: From prototypes to high-volume production runs.

- Material Expertise: Ensuring optimal performance for your specific environment.

- Precision Production: Guaranteeing quality and reliability in every part.

Let us help you solve your most challenging sealing problems. Contact our engineering team today to discuss your application requirements.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance