When it comes to performance under sustained pressure, Teflon encapsulated O-rings exhibit excellent compression set resistance. This ability to rebound after being compressed is a direct result of their unique two-part construction, which combines an elastomeric core with a durable outer jacket. This design ensures they maintain a reliable seal over long periods, meeting or exceeding the demanding requirements of standards like L-P389A and ASTM-D-2166.

The core challenge in many sealing applications is finding a material that resists both chemical attack and mechanical failure. Teflon encapsulated O-rings solve this by using an elastic inner core for flexibility and a seamless Teflon shell for protection, resulting in a seal with a very low compression set.

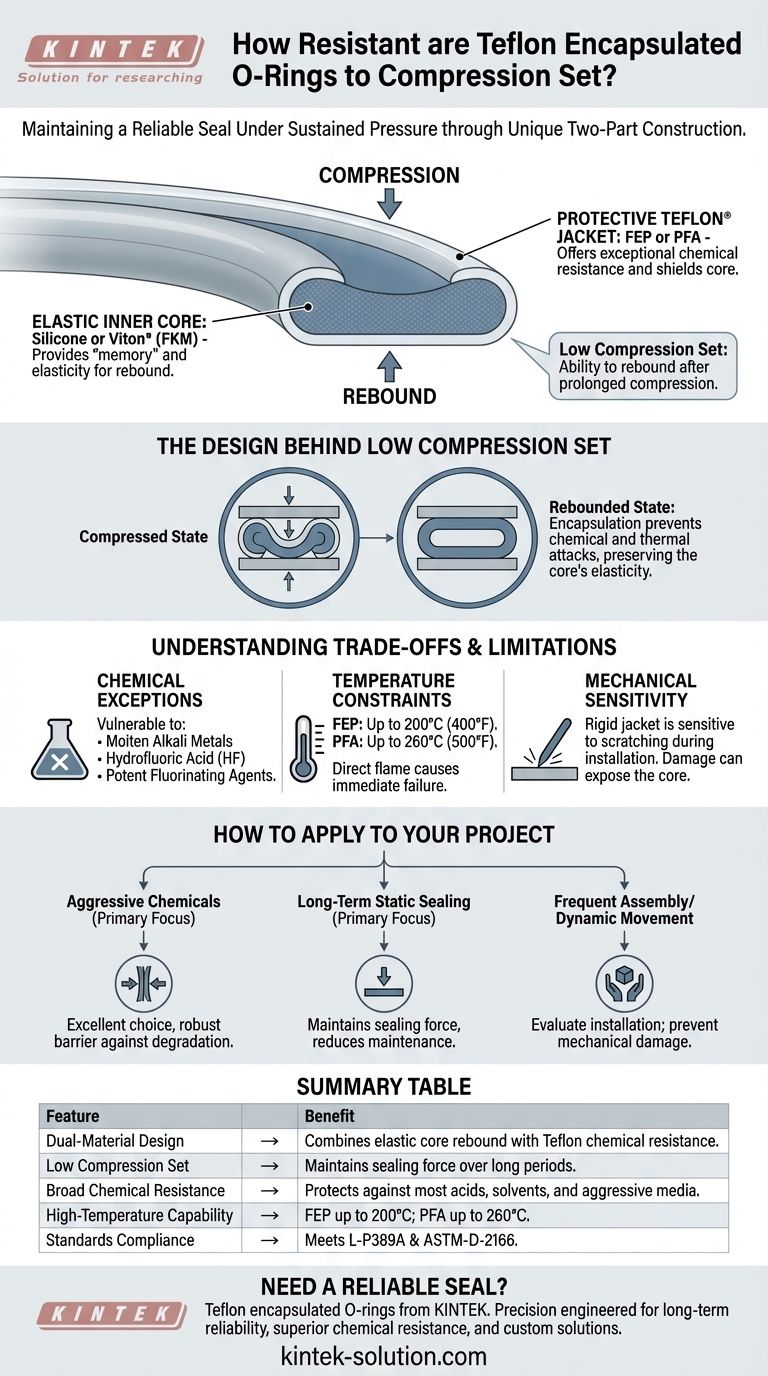

The Design Behind Low Compression Set

The superior performance of these O-rings is not due to a single material, but to the intelligent combination of two. Each component plays a distinct and critical role in maintaining the seal's integrity.

The Elastic Inner Core

The center of the O-ring is made from a resilient elastomer, typically Silicone or Viton® (FKM). This core is responsible for the seal's "memory" and elasticity.

When the O-ring is compressed, it's the core that deforms and then pushes back, creating the force necessary for a tight, reliable seal.

The Protective Teflon® Jacket

The elastomeric core is seamlessly encapsulated within a thin, tough jacket of Teflon® (usually FEP or PFA). This outer layer is what faces the hostile environment.

Its primary role is to provide exceptional chemical resistance, protecting the sensitive inner core from degradation by acids, solvents, and other aggressive media.

How This Prevents Permanent Deformation

Compression set occurs when a material loses its ability to return to its original shape after prolonged compression. This leads to seal failure.

The encapsulated design prevents this by shielding the elastic core from chemical and thermal attacks that would otherwise cause it to harden, swell, or degrade, thus preserving its ability to rebound.

Understanding the Trade-offs and Limitations

While highly resilient, Teflon encapsulated O-rings are not universally applicable. Understanding their operational boundaries is crucial for successful implementation.

Chemical Exceptions

Despite their broad chemical resistance, they are vulnerable to a few specific substances. Exposure to molten alkali metals (like sodium), hydrofluoric acid (HF), and extremely potent fluorinating agents can compromise the Teflon jacket.

Temperature Constraints

The Teflon jacket has a high melting point, but the operational temperature of the entire O-ring is more limited.

FEP encapsulated seals are typically rated up to 200°C (400°F), while PFA versions can handle up to 260°C (500°F). Direct flame exposure will cause immediate failure.

Mechanical Sensitivity

The Teflon jacket, while durable, is more rigid and less forgiving than a standard elastomer O-ring.

Care must be taken during installation to avoid scratching or nicking the surface. Any damage to the jacket can create a leak path and expose the inner core to chemical attack, negating the primary benefit of the design.

How to Apply This to Your Project

To determine if this is the right seal for your needs, consider your primary operational challenge.

- If your primary focus is sealing against aggressive chemicals: These O-rings are an excellent choice, providing a robust barrier where standard elastomers would quickly degrade and fail.

- If your primary focus is long-term static sealing: Their low compression set ensures they will maintain sealing force for extended periods, reducing maintenance and preventing leaks in critical systems.

- If your application involves frequent assembly or dynamic movement: You must carefully evaluate installation procedures and surface finishes to prevent mechanical damage to the rigid Teflon jacket.

By understanding both their exceptional resilience and their specific limitations, you can deploy Teflon encapsulated O-rings with confidence for long-term, reliable sealing.

Summary Table:

| Feature | Benefit |

|---|---|

| Dual-Material Design | Combines an elastic core for rebound with a Teflon jacket for chemical resistance. |

| Low Compression Set | Maintains sealing force and integrity over long periods of static compression. |

| Broad Chemical Resistance | Protects against most acids, solvents, and aggressive media (exceptions apply). |

| High-Temperature Capability | PFA jackets rated up to 260°C (500°F); FEP jackets up to 200°C (400°F). |

| Standards Compliance | Meets or exceeds requirements of standards like L-P389A and ASTM-D-2166. |

Need a Reliable Seal for Demanding Conditions?

Teflon encapsulated O-rings from KINTEK are engineered for precision and durability. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE components—from prototypes to high-volume orders—are designed to solve your toughest sealing challenges.

We deliver:

- Long-term sealing reliability with minimal compression set.

- Superior chemical resistance to protect your critical processes.

- Custom solutions tailored to your specific application requirements.

Let's engineer your solution. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials