In the electrical and electronics industry, Polytetrafluoroethylene (PTFE) is primarily used as a high-performance insulator and protective material. Its applications range from wire and cable insulation, especially for high-frequency signals, to the construction of printed circuit boards (PCBs), capacitors, and connectors, and as a non-reactive shield for components during manufacturing processes like soldering.

PTFE's value extends beyond simple insulation. Its unique combination of electrical properties—particularly its low dielectric constant and low dissipation factor—makes it the material of choice for demanding, high-frequency applications where preserving signal integrity is more critical than cost.

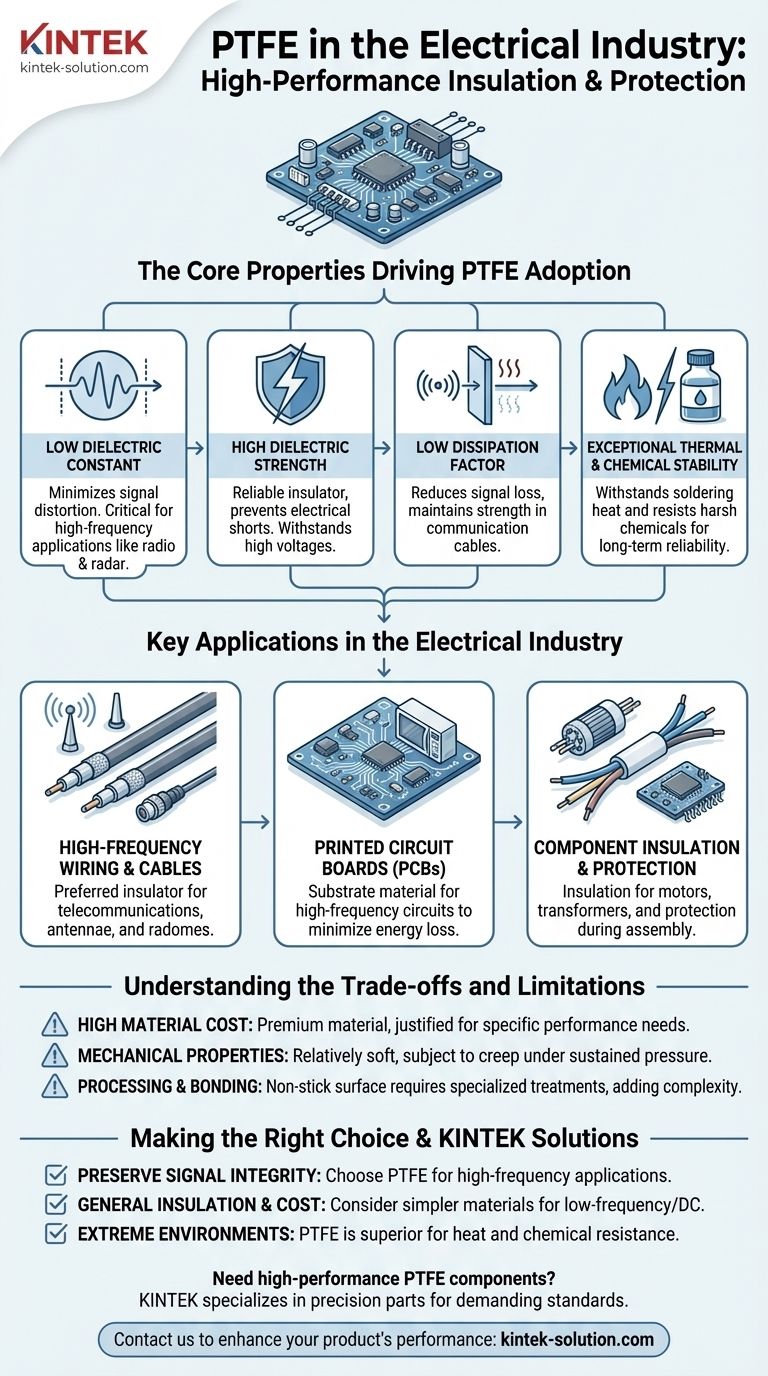

The Core Properties Driving PTFE Adoption

The widespread use of PTFE is not accidental; it stems from a specific set of electrical, thermal, and chemical properties that make it uniquely suited for challenging electronic environments. Understanding these fundamentals is key to appreciating its value.

Low Dielectric Constant

A material's dielectric constant measures how much electrical energy it can store when subjected to an electric field. PTFE has one of the lowest dielectric constants of any solid material.

This means it interferes very little with the electrical signal passing through an insulated wire, preventing signal distortion. This property is absolutely critical for high-frequency applications like radio, radar, and high-speed data transmission.

High Dielectric Strength

Dielectric strength is a measure of a material's ability to act as an insulator. It defines the maximum voltage a material can withstand before it breaks down and allows electricity to arc through it.

PTFE possesses a very high dielectric strength, making it a reliable insulator for a wide range of voltages and preventing electrical shorts.

Low Dissipation Factor

The dissipation factor, or loss tangent, indicates how much of a signal's energy is lost as heat while passing through the insulating material.

PTFE has an extremely low dissipation factor. This ensures that minimal signal power is wasted, which is essential for maintaining signal strength in communication cables and improving efficiency in components like capacitors.

Exceptional Thermal and Chemical Stability

Beyond its electrical characteristics, PTFE is famously inert and temperature-resistant.

It can withstand the high temperatures of soldering and heat-sealing processes without degrading. It is also resistant to virtually all corrosive chemicals, protecting sensitive components in harsh industrial or aerospace environments.

Key Applications in the Electrical Industry

These fundamental properties translate directly into specific, high-value applications where lesser materials would fail.

High-Frequency Wiring and Cables

PTFE is the preferred insulator for coaxial cables used in telecommunications, antennae, and radomes. Its low dielectric constant and low loss ensure that the high-frequency signals arrive with maximum clarity and strength.

Printed Circuit Boards (PCBs)

For circuits that operate at microwave or radio frequencies, PTFE is often used as the substrate material for the PCB itself. This minimizes energy loss between components and preserves the integrity of the sensitive signals traveling across the board.

Component Insulation and Protection

PTFE is used to create insulation for wires and components inside motors, transformers, and control devices. Its durability ensures long-term reliability.

Additionally, its non-reactive nature makes it ideal for protecting delicate electronic parts from heat and chemicals during assembly and manufacturing.

Understanding the Trade-offs and Limitations

While its performance is exceptional, PTFE is not the universal solution for every electrical application. Acknowledging its trade-offs is crucial for making an informed engineering decision.

High Material Cost

PTFE is a premium polymer, and its cost is significantly higher than common insulators like PVC or Polyethylene. Its use is typically justified only when its specific high-performance characteristics are required.

Mechanical Properties

PTFE is a relatively soft material that can be subject to "creep," or deformation under sustained pressure. It is not suitable for applications requiring high structural strength or rigidity without reinforcement.

Processing and Bonding

PTFE's inert, non-stick surface makes it very difficult to bond to other materials using conventional adhesives. Specialized surface treatments or etching processes are often required, adding complexity and cost to manufacturing.

Making the Right Choice for Your Application

Selecting the right material requires balancing performance needs with practical constraints.

- If your primary focus is preserving signal integrity in high-frequency applications (e.g., radio, radar, high-speed data): PTFE is often the best choice due to its exceptionally low dielectric constant and loss factor.

- If your primary focus is general insulation in low-frequency or DC applications where cost is a major driver: Simpler, less expensive materials like PVC or Polyethylene may be more suitable.

- If your primary focus is reliability in extreme thermal or chemical environments: PTFE's inherent resistance to heat and corrosive agents makes it a superior and highly reliable option.

Ultimately, selecting PTFE is an engineering decision to prioritize electrical performance and environmental stability where other materials would fail.

Summary Table:

| Property | Benefit for Electrical Applications |

|---|---|

| Low Dielectric Constant | Minimizes signal distortion in high-frequency wiring (e.g., RF cables). |

| High Dielectric Strength | Provides reliable insulation, preventing electrical shorts. |

| Low Dissipation Factor | Reduces signal loss, crucial for communication systems. |

| Thermal/Chemical Stability | Withstands soldering heat and harsh environments for long-term reliability. |

Need high-performance PTFE components for your electrical application?

KINTEK specializes in manufacturing precision PTFE parts—including seals, liners, labware, and custom components—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your components meet the demanding electrical, thermal, and chemical standards of your industry.

Contact us today to discuss how our custom PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support