In food processing, Polytetrafluoroethylene (PTFE) is primarily used for its unique combination of three properties: an extremely non-stick surface, chemical inertness, and high-temperature resistance. This makes it an ideal material for applications ranging from coatings on industrial baking sheets and cookware to critical machinery components like conveyor belts, seals, and valves, where preventing food adhesion and ensuring purity are paramount.

The core value of PTFE in the food industry is not just that it's non-stick; it's that this property, combined with its chemical and thermal stability, directly solves the industry's fundamental challenges of maintaining hygiene, maximizing efficiency, and preserving product integrity.

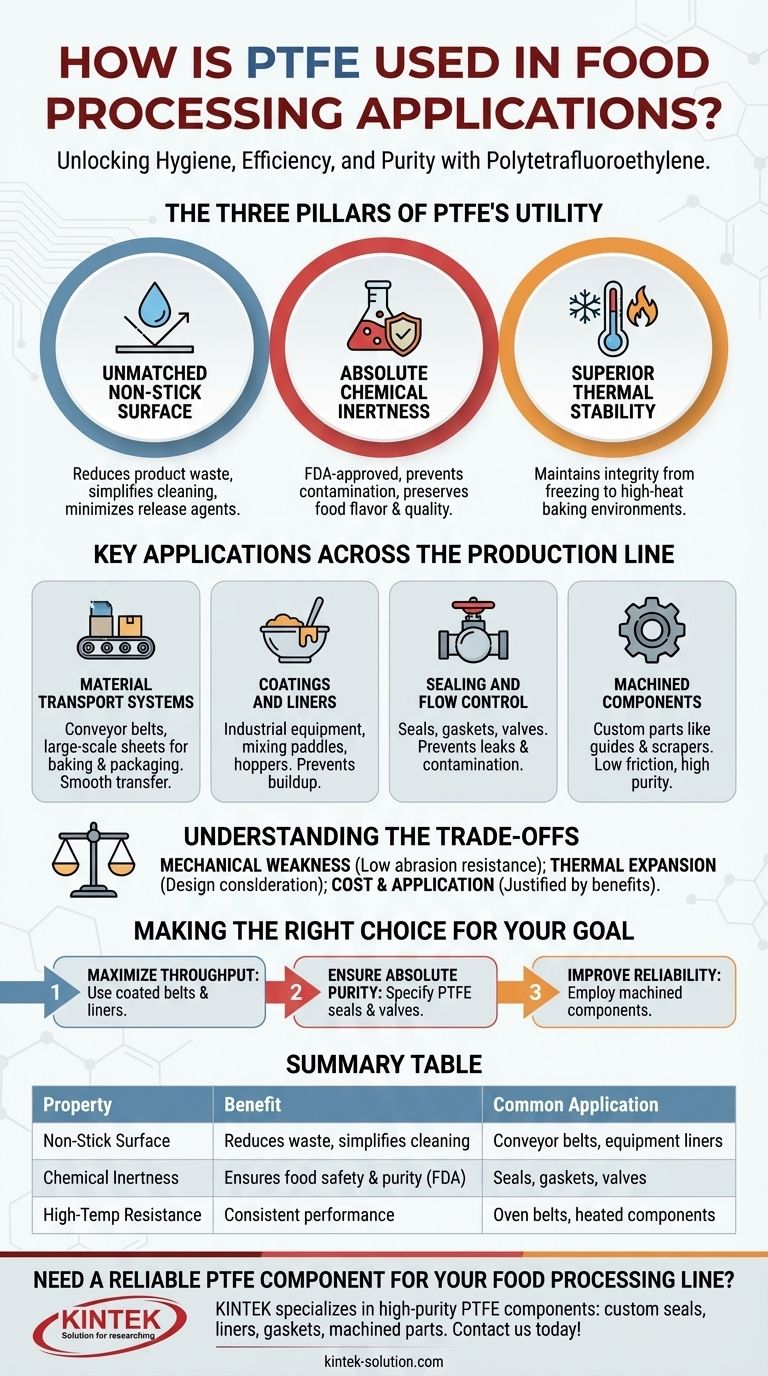

The Three Pillars of PTFE's Utility

The effectiveness of PTFE in food processing applications is built on three essential material characteristics. Understanding these properties reveals why it has become a standard in the industry.

Unmatched Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material. This creates a surface that food products release from with exceptional ease.

This property directly reduces product waste, as less material is left clinging to equipment. It also improves operational efficiency by minimizing the need for release agents like oils and fats and drastically simplifying cleaning procedures.

Absolute Chemical Inertness

PTFE is virtually non-reactive and does not contaminate the substances it touches. This is critical for food safety and regulatory compliance.

Materials like PTFE are often FDA-approved for food contact. This inertness ensures that it won't react with acidic ingredients (like tomato sauces) or alkaline substances, preserving the food's intended flavor and quality while preventing material degradation.

Superior Thermal Stability

Food processing often involves extreme temperatures, from freezing to high-heat baking. PTFE maintains its integrity across a wide temperature range.

This thermal stability allows PTFE-coated belts and sheets to be used directly in ovens and other high-temperature environments without breaking down or releasing harmful substances, ensuring consistent performance and safety.

Key Applications Across the Production Line

PTFE is not a single-use solution but a versatile material integrated into various stages of food processing to improve safety and efficiency.

Material Transport Systems

PTFE is frequently used for conveyor belts and large-scale sheets in processes like baking, confectionery production, and packaging. Its non-stick surface ensures a smooth transfer of products without sticking, breaking, or deforming.

Coatings and Liners

Perhaps its most well-known use, non-stick coatings are applied to industrial equipment just as they are to consumer cookware. This prevents food buildup on mixing paddles, hoppers, and chutes, ensuring consistent flow and easier maintenance.

Sealing and Flow Control

In the form of seals, gaskets, washers, and packings, PTFE prevents leaks and contamination between different parts of a processing system. Its chemical resistance ensures the seals themselves do not become a source of contamination.

PTFE valves are also crucial for controlling the flow of fluids, including corrosive or sensitive ingredients, without reacting with them or requiring frequent maintenance.

Machined Components

Because it can be formed into solid shapes like extruded rods, PTFE is used to create custom machinery components. These parts, such as guides and scrapers, benefit from low friction and high purity, preventing food from sticking or becoming contaminated within the machinery.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Mechanical Weakness

Compared to metals, PTFE is a soft material with low abrasion resistance. In high-wear applications where it faces significant mechanical stress or scraping, it can degrade more quickly than harder materials.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion. Engineers must account for this in designs that span a wide temperature range, as components can change size and shape, potentially affecting tolerances.

Cost and Application

The process of applying PTFE coatings or machining solid PTFE components can be more expensive than using traditional materials like stainless steel or other plastics. Its use must be justified by the specific benefits it brings to hygiene and efficiency.

Making the Right Choice for Your Goal

Integrating PTFE effectively requires aligning the material's strengths with your primary operational objective.

- If your primary focus is maximizing production throughput: Utilize PTFE-coated conveyor belts and equipment liners to ensure easy product release and dramatically reduce cleaning-related downtime.

- If your primary focus is ensuring absolute food purity: Specify PTFE for all food-contact seals, gaskets, and valves, especially when processing acidic, alkaline, or otherwise sensitive ingredients.

- If your primary focus is improving machinery reliability: Employ machined PTFE components for low-friction guides and rollers to reduce wear on moving parts and minimize maintenance schedules.

Ultimately, integrating PTFE correctly allows food processors to achieve a higher standard of safety, efficiency, and product quality.

Summary Table:

| Property | Benefit in Food Processing | Common Application |

|---|---|---|

| Non-Stick Surface | Reduces waste, simplifies cleaning | Conveyor belts, equipment liners |

| Chemical Inertness | Ensures food safety & purity (FDA-approved) | Seals, gaskets, valves |

| High-Temp Resistance | Consistent performance from freezing to baking | Oven belts, heated equipment components |

Need a reliable PTFE component for your food processing line?

KINTEK specializes in manufacturing high-purity PTFE components—including custom seals, liners, gaskets, and machined parts—for the semiconductor, medical, laboratory, and food processing industries. We prioritize precision and offer custom fabrication from prototypes to high-volume orders to ensure your equipment meets the highest standards of hygiene and efficiency.

Contact us today to discuss your specific application and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability