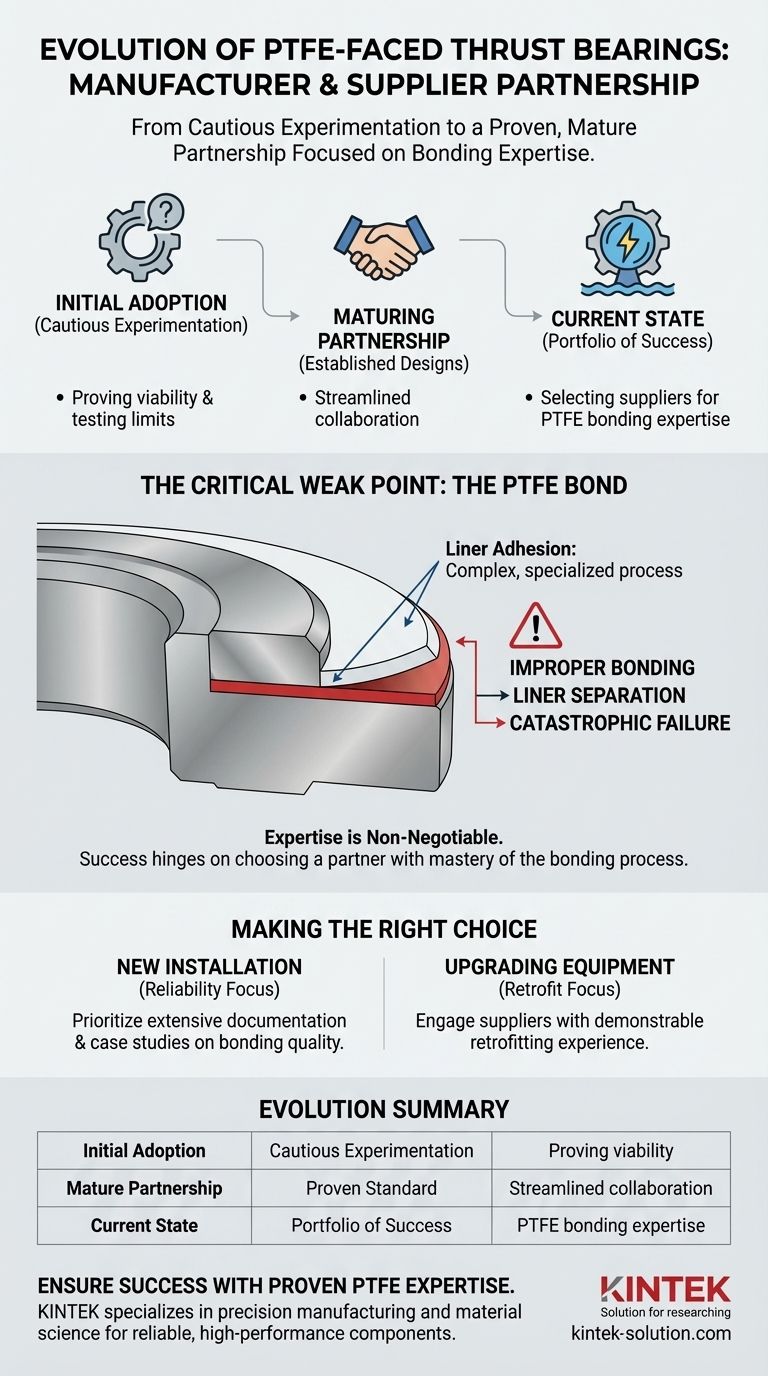

The relationship between machinery manufacturers and bearing suppliers regarding PTFE-faced thrust bearings has fundamentally evolved from cautious experimentation to a mature, proven partnership. This maturity is demonstrated by the significant and growing portfolio of successful new installations, particularly in demanding applications like hydrogenerators.

The core of this evolution is a shift in focus. The question is no longer if PTFE bearings work, but rather who can manufacture them to work reliably. Success now hinges on selecting a supplier with deep, verifiable expertise in the critical PTFE bonding process.

From Novelty to a Proven Standard

The adoption of PTFE-faced bearings marks a significant technological advancement in rotating machinery. Understanding the journey from a novel concept to an industry staple clarifies the current state of supplier relationships.

The Initial Cautious Adoption

Initially, the use of PTFE as a bearing surface was a specialized solution. Machinery manufacturers and end-users were understandably cautious, working closely with a select few bearing suppliers to test the material's limits and prove its viability in real-world conditions.

A Maturing Partnership

Today, that relationship has matured significantly. The "what if" phase is over, replaced by established design principles and a shared understanding of performance expectations. This allows for more streamlined collaboration on new projects.

Evidence of Success: The Hydrogenerator Portfolio

The most compelling evidence of this maturity is the existence of a substantial portfolio of new hydrogenerator installations that rely on PTFE-faced thrust bearings. These critical, high-load applications serve as definitive proof that the technology is robust, reliable, and trusted by the industry.

The Critical Weak Point: The PTFE Bond

While the technology is proven, it is not without a critical point of potential failure. The success of the entire bearing assembly depends on one highly specialized manufacturing step.

The Challenge of Liner Adhesion

The primary technical hurdle is the permanent bonding of the thin PTFE liner to its metal backing pad. This is a complex process requiring specialized knowledge, equipment, and stringent quality control.

The Consequence of Improper Bonding

An improper or failed bond is the single greatest risk. This can lead to liner separation, which causes a rapid degradation of the bearing surface.

This degradation can quickly escalate into a catastrophic failure of the entire bearing, resulting in significant machinery damage and costly downtime.

Why Expertise is Non-Negotiable

Because of this high-stakes failure mode, a supplier's experience is not just a preference; it is a fundamental requirement. The relationship has evolved to the point where manufacturers must scrutinize a bearing supplier's specific knowledge and track record in the bonding process itself.

Making the Right Choice for Your Application

Selecting the right partner is paramount when specifying PTFE-faced thrust bearings. Your evaluation criteria should be weighted heavily toward manufacturing expertise and proven performance.

- If your primary focus is reliability for a new installation: Prioritize suppliers who can provide extensive documentation and case studies specifically related to their PTFE bonding processes and quality control measures.

- If your primary focus is upgrading existing equipment: Engage a supplier with demonstrable experience in retrofitting machinery, as this often presents unique challenges that require a deeper level of engineering collaboration.

Ultimately, successful implementation of modern PTFE bearings depends less on the material itself and more on choosing a manufacturing partner with proven mastery over the production process.

Summary Table:

| Evolution Phase | Key Characteristic | Focus of Partnership |

|---|---|---|

| Initial Adoption | Cautious Experimentation | Proving viability and testing limits. |

| Mature Partnership | Proven Standard | Streamlined collaboration on established designs. |

| Current State | Portfolio of Success | Selecting suppliers based on PTFE bonding expertise. |

Ensure Your Project's Success with Proven PTFE Expertise

The evolution of PTFE-faced thrust bearings highlights that reliability is no longer about the material, but about the manufacturer's mastery of the critical bonding process. At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including seals, liners, and custom fabrications.

Our deep expertise in material science and stringent quality control ensures that every component we produce meets the highest standards for durability and performance. Whether you are designing new machinery or upgrading existing equipment, partnering with KINTEK mitigates the risk of liner failure and guarantees a reliable solution.

Contact us today to discuss how our custom PTFE solutions can enhance the reliability and efficiency of your applications in the semiconductor, medical, laboratory, and industrial sectors.

Get in touch with our experts to start your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability