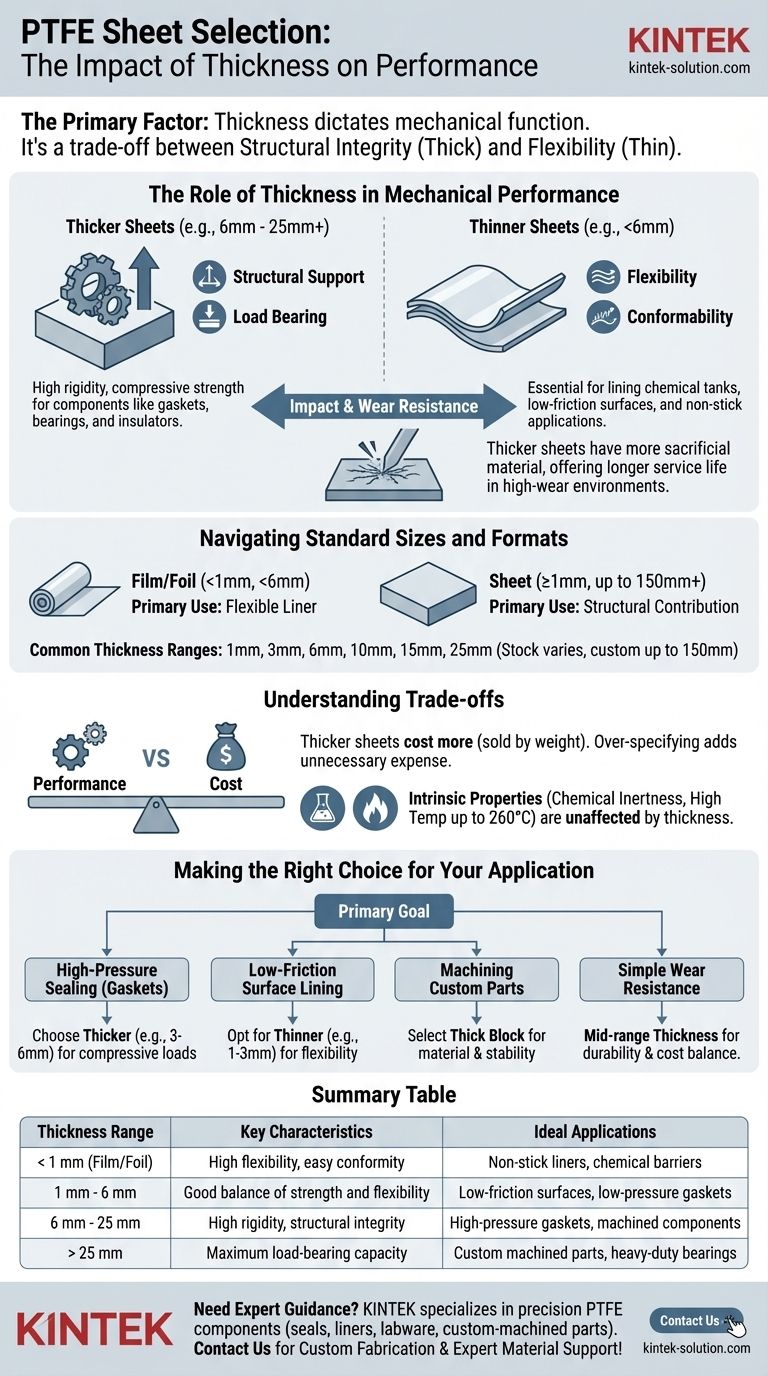

In selecting a PTFE sheet, thickness is the primary factor that dictates its mechanical function and suitability for an application. Thicker sheets are chosen for their structural integrity and ability to withstand high loads in applications like gaskets or machined parts. Conversely, thinner sheets provide flexibility and are ideal for low-stress uses such as non-stick liners or chemical barriers where conformity to a surface is key.

The choice of PTFE sheet thickness is fundamentally a trade-off between mechanical strength and material flexibility. You are balancing the need for the sheet to act as a structural component against its ability to serve as a pliable surface layer.

The Role of Thickness in Mechanical Performance

The physical thickness of a PTFE sheet directly correlates with its strength, rigidity, and overall durability. Understanding how this single dimension affects performance is crucial for proper material selection.

Structural Support and Load Bearing

Thicker PTFE sheets, often in the 6 mm to 25 mm range or greater, offer significant rigidity and compressive strength. This makes them suitable for applications that require structural support.

These sheets can be machined into custom components like bearings, insulators, or blocks. For high-pressure gaskets, a thicker sheet ensures a durable seal that resists being crushed or extruded under load.

Flexibility and Conformability

Thinner sheets, typically under 6 mm, are much more flexible. This property is essential when the PTFE needs to conform to a contoured surface.

Applications like lining chemical tanks, creating low-friction sliding surfaces, or acting as a non-stick coating benefit from a thinner material's ability to bend without cracking.

Impact and Wear Resistance

While all PTFE offers excellent wear resistance, a thicker sheet inherently has more material to abrade away over its service life.

In high-wear environments, such as slide plates or wear strips, a thicker sheet provides a longer lifespan simply because there is more sacrificial material available.

Navigating Standard Sizes and Formats

Suppliers offer PTFE in a range of standard thicknesses, but it's important to understand the terminology and what is commonly available.

"Sheet" vs. "Film" Distinction

Generally, PTFE material with a thickness below 6 mm, and especially below 1 mm, may be categorized as PTFE film or foil.

This distinction matters because "film" implies a primary use as a flexible liner or barrier, whereas "sheet" implies some level of structural contribution.

Common Thickness Ranges

Standard stock thicknesses for PTFE sheets often include options like 1mm, 3mm, 6mm, 10mm, 15mm, and 25mm. Specialized suppliers can provide sheets up to 150 mm thick.

Always verify available stock with your specific supplier, as their standard offerings may vary.

The Role of Custom Cutting

Most suppliers offer custom cutting services. This allows you to specify the exact length and width you need, but the thickness remains the primary selection criteria you must determine based on your application's demands.

Understanding the Trade-offs

Choosing the correct thickness is not about finding the thickest option, but the most appropriate one. An incorrect choice leads to either premature failure or unnecessary cost.

Performance vs. Cost

The most significant trade-off is cost. PTFE is sold by weight, so a 10 mm thick sheet will cost substantially more than a 5 mm sheet of the same dimensions.

Over-specifying the thickness does not add value if the application does not demand the extra structural strength; it only adds unnecessary expense.

Beyond Thickness: Intrinsic Properties

Remember that thickness only affects mechanical properties. Key characteristics of PTFE, like its chemical inertness and high-temperature resistance (up to 260°C / 500°F), are intrinsic to the material itself.

A 2 mm sheet will resist the same harsh chemicals as a 20 mm sheet. Your selection should first confirm PTFE is suitable for the chemical and thermal environment, then use thickness to meet the physical demands.

Making the Right Choice for Your Application

Use your primary goal to guide your decision on thickness.

- If your primary focus is high-pressure sealing (gaskets): Choose a thicker sheet (e.g., 3 mm to 6 mm) that can withstand compressive loads without being extruded.

- If your primary focus is a low-friction surface lining: Opt for a thinner sheet (e.g., 1 mm to 3 mm) that is flexible enough to conform to the substrate.

- If your primary focus is machining custom parts: Select a thick block or sheet that provides enough raw material and structural stability for the final component's dimensions and load requirements.

- If your primary focus is simple wear resistance: A mid-range thickness offers a good balance of durability and cost for applications like slide pads or wear strips.

Ultimately, matching the sheet's thickness to the specific mechanical stresses of your project ensures both reliable performance and cost-effectiveness.

Summary Table:

| Thickness Range | Key Characteristics | Ideal Applications |

|---|---|---|

| < 1 mm (Film/Foil) | High flexibility, easy conformity | Non-stick liners, chemical barriers |

| 1 mm - 6 mm | Good balance of strength and flexibility | Low-friction surfaces, low-pressure gaskets |

| 6 mm - 25 mm | High rigidity, structural integrity | High-pressure gaskets, machined components |

| > 25 mm | Maximum load-bearing capacity | Custom machined parts, heavy-duty bearings |

Need Expert Guidance on Your PTFE Sheet Selection?

Choosing the right PTFE thickness is critical for your application's success. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom-machined parts—for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Custom fabrication from prototypes to high-volume orders

- Expert material selection support to match thickness to your mechanical and chemical requirements

- Precision production ensuring reliable performance in demanding environments

Let our team help you optimize your PTFE solution for durability, cost-effectiveness, and performance. Contact us today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs