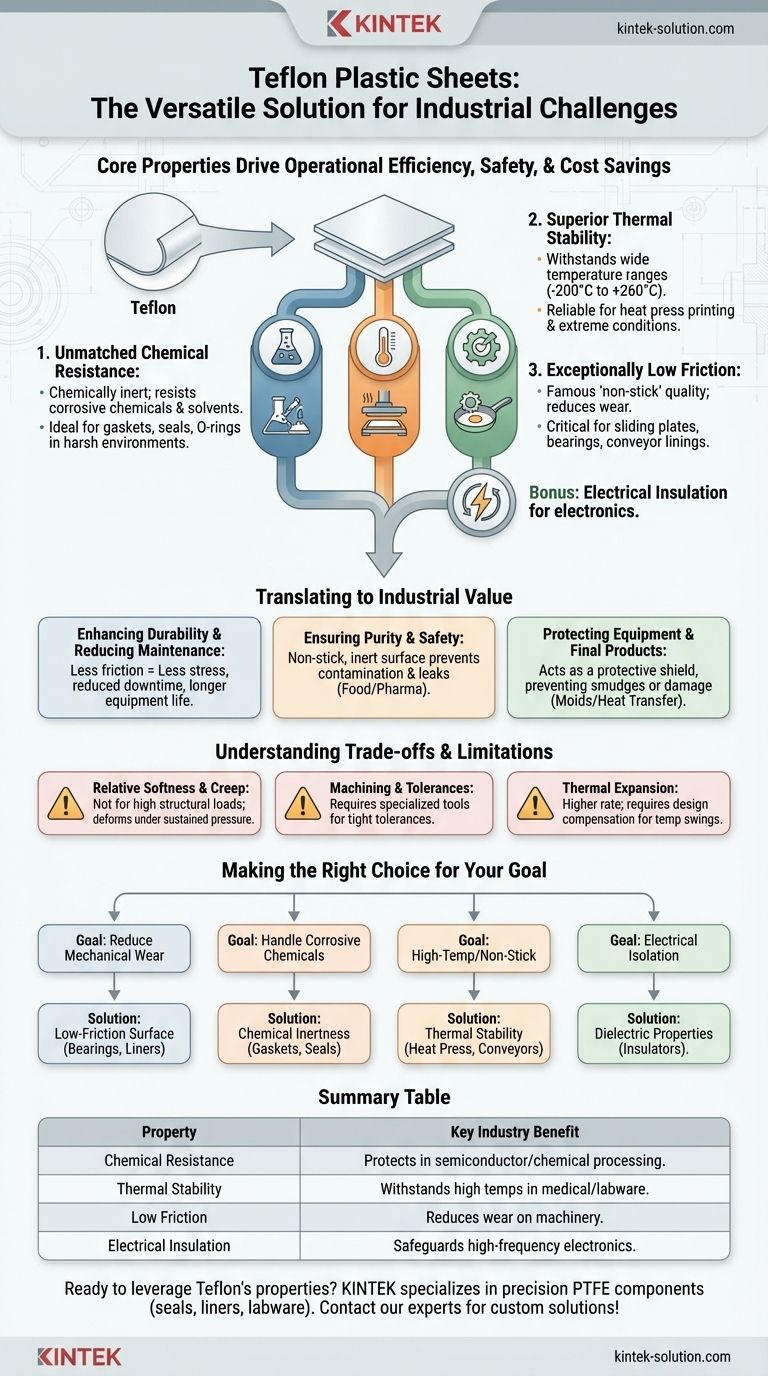

At its core, the versatility of Teflon plastic sheets stems from a unique combination of three fundamental properties: extreme chemical resistance, high thermal stability, and an exceptionally low coefficient of friction. This powerful trifecta allows a single material to solve critical, yet vastly different, problems across industries ranging from aerospace and electronics to food production and chemical processing.

The true value of Teflon is not simply its versatility, but how its core properties translate directly into improved operational efficiency, enhanced safety, and significant cost savings by protecting equipment, preventing contamination, and reducing mechanical wear.

The Three Pillars of Teflon's Performance

To understand Teflon's wide-ranging impact, we must first examine the distinct properties that make it a go-to material for complex engineering challenges.

Unmatched Chemical Resistance

Teflon (PTFE) is almost completely chemically inert, meaning it resists reaction with nearly all corrosive chemicals and industrial solvents.

This makes it an ideal material for creating a protective barrier in harsh environments. It's extensively used for gaskets, seals, O-rings, and valve seats in the chemical processing and automotive industries, ensuring seal integrity under extreme conditions.

Superior Thermal Stability

Teflon sheets can withstand a wide range of temperatures without degrading, making them reliable for both high-heat and moderately cold applications.

A classic example is in heat press printing. A Teflon sheet provides a reusable, non-stick surface that endures high temperatures, protecting both the fabric from scorching and the heat platen from ink or adhesive buildup.

Exceptionally Low Friction

Teflon has one of the lowest coefficients of friction of any known solid material, giving it its famous "non-stick" quality.

This property is critical for industrial machinery. Using Teflon for sliding plates, bearings, or conveyor linings reduces wear and tear on moving parts, minimizes the need for liquid lubricants, and extends the lifespan of the equipment.

The Added Benefit of Electrical Insulation

Beyond these three pillars, Teflon is also an excellent electrical insulator.

Its ability to resist the flow of electricity makes it a valuable component in the electronics and electrical industries, used for insulating wires, cables, and sensitive components, especially in high-frequency applications.

How These Properties Translate to Industrial Value

The physical properties of Teflon are impressive, but their true benefit lies in the tangible, real-world advantages they provide in an industrial setting.

Enhancing Durability and Reducing Maintenance

By minimizing friction between moving parts, Teflon components directly reduce the mechanical stress that leads to breakdowns.

This results in less equipment downtime for repairs, a reduced need for frequent lubrication schedules, and a longer operational life for machinery, all of which lead to significant cost savings.

Ensuring Purity and Safety

In food processing and pharmaceutical manufacturing, Teflon's non-stick, chemically inert surface prevents materials from sticking to equipment and ensures that no chemicals from the components leach into the product.

This guarantees product purity and simplifies cleaning processes, enhancing both safety and efficiency. In chemical handling, its reliability in seals prevents dangerous leaks.

Protecting Equipment and Final Products

Teflon sheets act as a protective shield. In heat transfer applications, they ensure flawless, clean prints by preventing smudges or stains.

This principle of protection extends to manufacturing molds, where a Teflon lining can act as a release agent, or to any process where a durable, non-stick, non-reactive surface is needed to preserve the integrity of a product or machine.

Understanding the Trade-offs

No material is perfect for every application. Being an effective technical advisor means acknowledging limitations.

Relative Softness and Creep

Teflon is not a high-strength structural plastic. Under a sustained, heavy load, it can slowly deform over time in a process known as "creep." This makes it unsuitable for high-load structural components.

Machining and Tolerances

While Teflon can be customized via CNC machining, its relative softness requires specialized tools and techniques to achieve the same tight tolerances that are possible with metals or harder plastics.

Thermal Expansion

Teflon has a higher rate of thermal expansion than many other engineering materials. This must be accounted for in designs where components will undergo significant temperature swings to avoid binding or failure.

Making the Right Choice for Your Goal

To apply this knowledge effectively, match Teflon's strengths to your primary industrial challenge.

- If your primary focus is reducing mechanical wear: Its low-friction surface is ideal for creating self-lubricating bearings, liners, and sliding plates.

- If your primary focus is handling corrosive chemicals: Its chemical inertness makes it the definitive choice for gaskets, seals, and linings in aggressive environments.

- If your primary focus is high-temperature, non-stick applications: Its thermal stability is perfect for heat press sheets, food processing conveyors, and mold release liners.

- If your primary focus is electrical isolation: Its excellent dielectric properties make it a reliable insulator for high-frequency electronics and components.

By understanding these core properties and their practical trade-offs, you can leverage Teflon not just as a material, but as a strategic solution to complex engineering challenges.

Summary Table:

| Teflon Property | Key Industry Benefit |

|---|---|

| Chemical Resistance | Protects against corrosive chemicals in semiconductor and chemical processing. |

| Thermal Stability | Withstands high temperatures in medical device sterilization and labware. |

| Low Friction | Reduces wear on industrial machinery and sliding components. |

| Electrical Insulation | Safeguards high-frequency electronics and sensitive components. |

Ready to leverage Teflon's unique properties for your application? KINTEK specializes in manufacturing precision PTFE components (seals, liners, labware, etc.) for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders to ensure your equipment benefits from enhanced durability, safety, and cost savings. Contact our experts today to discuss your specific needs and get a custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications