In essence, the PTFE layer adds a dedicated, low-friction sliding surface to an elastomeric bearing. This allows the bearing to accommodate large horizontal movements, such as those from thermal expansion or seismic activity, which a standard elastomeric pad cannot handle on its own. It effectively separates the function of supporting vertical loads from the function of allowing horizontal displacement.

The core purpose of adding a PTFE layer is to decouple the bearing's functions. The elastomer handles vertical loads and rotational movement, while the ultra-low-friction PTFE surface allows for significant, unrestricted horizontal sliding. This dual-component design creates a far more versatile and capable structural support.

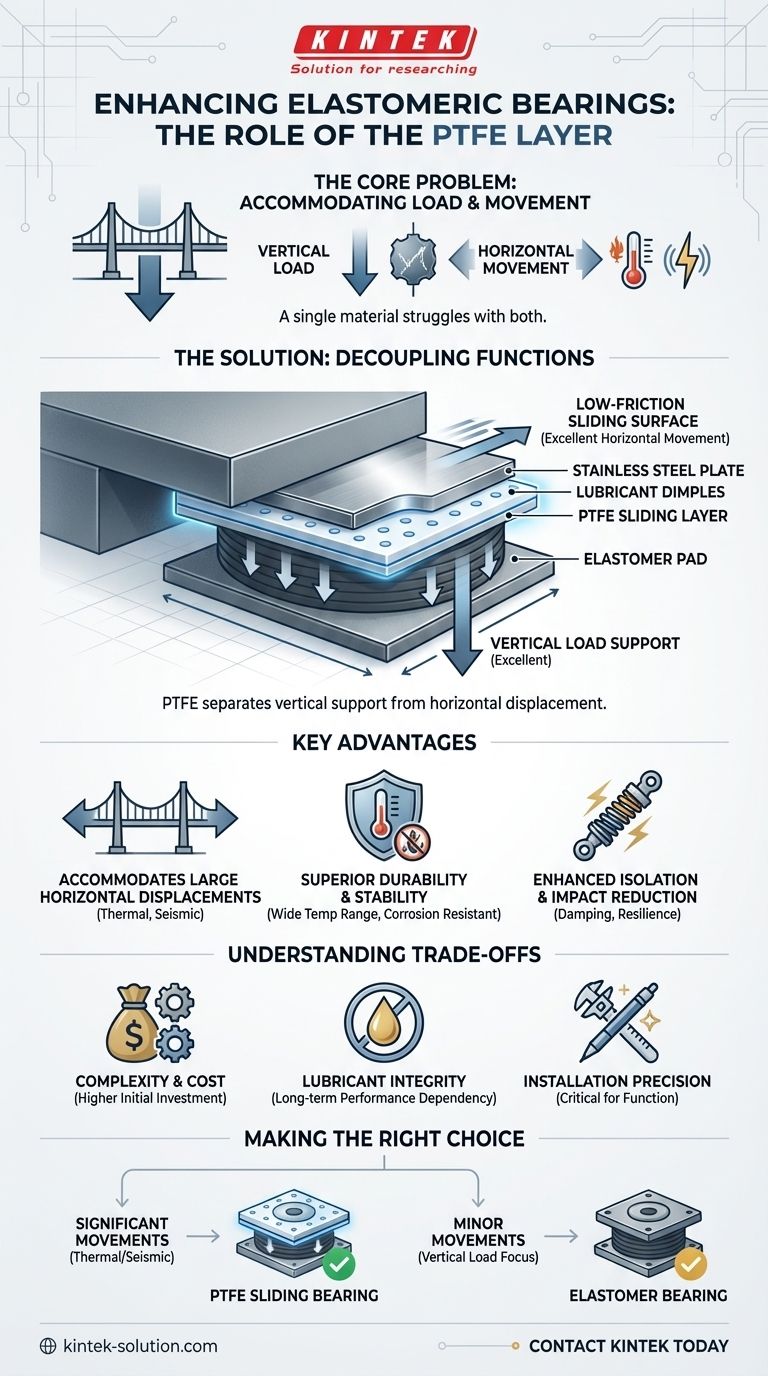

The Core Problem: Accommodating Both Load and Movement

Bridge structures must solve two competing problems: they need to support immense vertical weight while also allowing for constant horizontal movement caused by temperature changes, traffic loads, and seismic events. A single material often struggles to do both jobs optimally.

The Role of the Elastomer

The base elastomeric pad is excellent at its primary job: supporting heavy vertical loads. Its inherent flexibility also allows it to absorb vibrations and accommodate small rotations at the end of a bridge beam. However, its capacity for large horizontal shear deformation is limited.

The Role of the PTFE Layer

The PTFE (Polytetrafluoroethylene) layer introduces a dedicated sliding plane. It is bonded to the elastomeric bearing and slides against a polished stainless steel plate on the opposing structural element.

Because PTFE has an extremely low coefficient of friction, the two surfaces can slide past each other with minimal resistance. This is what enables the system to accommodate large horizontal displacements without transferring damaging stresses to the structure.

Enhancing Performance with Lubrication

To further reduce friction and ensure smooth, consistent movement over the bearing's lifespan, the PTFE surface often features small dimples. These dimples act as reservoirs, holding a silicone-based lubricant in place and preventing it from being squeezed out under pressure.

Key Advantages of a PTFE-Elastomeric System

Combining these two materials creates a system that leverages the strengths of both, resulting in a superior bearing for demanding applications.

Accommodating Large Horizontal Displacements

This is the primary advantage. By providing a sliding surface, the bearing can handle significant expansion and contraction cycles that would destroy a more rigid connection.

Superior Durability in Extreme Conditions

PTFE is an incredibly stable material. It retains its durability and low-friction properties across a wide temperature range, from near-zero to 250°C, outperforming standard elastomers in harsh environments. It also offers excellent corrosion resistance.

Enhanced Isolation and Impact Reduction

The combined flexibility of the elastomer and the sliding freedom of the PTFE help to isolate the structure from impact forces. This reduces the effect of live traffic loads and provides critical damping during an earthquake, improving the overall resilience of the bridge.

Understanding the Trade-offs

While highly effective, this composite design is not without its considerations. Understanding these is key to proper application.

Complexity and Cost

A PTFE sliding bearing is a more complex system to manufacture than a simple elastomeric pad. This multi-component design, requiring precise bonding and finishing, results in a higher initial cost.

Lubricant Integrity

The long-term performance of the bearing is dependent on the integrity of the lubricant sealed within the PTFE dimples. Contamination during installation or degradation over many decades could potentially increase the friction coefficient.

Installation Precision

The effectiveness of the sliding surface depends on the correct alignment and protection of both the PTFE and the stainless steel plate during construction. Any damage or misalignment can impede free movement and compromise the bearing's function.

Making the Right Choice for Your Application

The decision to use a PTFE-enhanced bearing depends entirely on the expected structural movements.

- If your primary focus is accommodating significant thermal expansion, shrinkage, or seismic displacement: The PTFE sliding elastomeric bearing is the correct and necessary choice.

- If your primary focus is supporting vertical loads with only minor expected rotation and horizontal movement: A standard, non-sliding elastomeric bearing may be a more cost-effective solution.

Ultimately, specifying a PTFE sliding bearing is a deliberate engineering choice to build more durable and resilient infrastructure.

Summary Table:

| Function | Elastomer's Role | PTFE Layer's Role |

|---|---|---|

| Vertical Load Support | Excellent: Compresses to support weight | Minimal direct role |

| Horizontal Movement | Limited capacity for shear deformation | Excellent: Provides low-friction sliding surface |

| Durability | Good, but limited by material properties | Excellent: Stable across wide temperature range, corrosion resistant |

| Application | Ideal for minor rotations/movements | Essential for large thermal expansion & seismic displacement |

Need a Reliable PTFE Component for Your Critical Bearing or Sealing Application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including seals, liners, and custom fabrications for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures the material integrity and low-friction performance that advanced elastomeric bearings depend on.

We partner with engineers to deliver solutions from prototype to high-volume production, guaranteeing the durability and precision your projects require.

Contact KINTEB today to discuss your specific PTFE needs and enhance your design's functionality and resilience.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability