In short, a PTFE coating transforms a standard thrust washer by creating an exceptionally low-friction, self-lubricating surface. This coating drastically reduces the resistance between moving parts, such as the spool and main gear in a fishing reel, leading to smoother operation, increased durability, and superior protection against wear and corrosion.

The core value of a PTFE-coated thrust washer isn't just about adding a layer of material; it's about fundamentally changing the component's surface properties to minimize energy loss from friction and extend the operational life of the entire assembly.

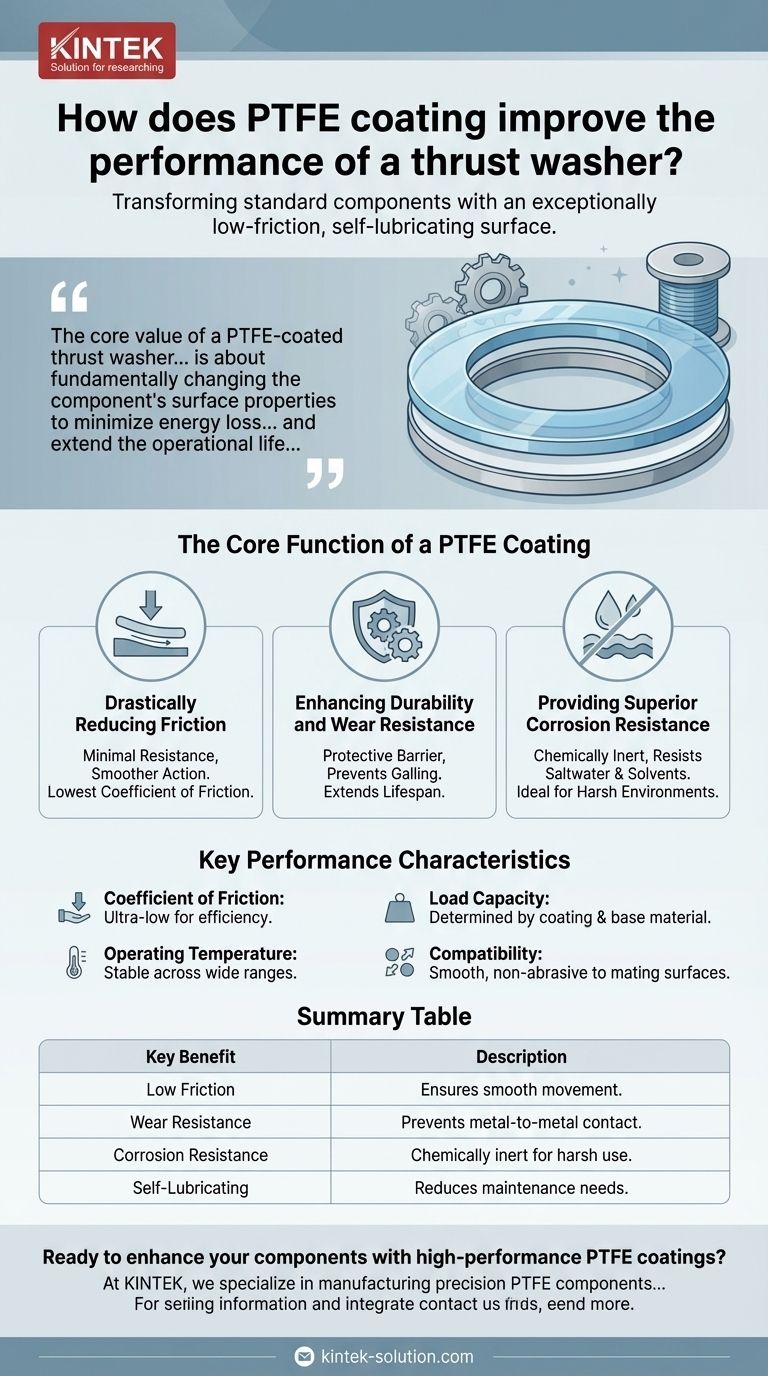

The Core Function of a PTFE Coating

Polytetrafluoroethylene (PTFE) is a synthetic polymer engineered for extreme performance. When applied as a coating, it imparts several key advantages to a mechanical component like a thrust washer.

Drastically Reducing Friction

The most significant benefit of PTFE is its remarkably low coefficient of friction—one of the lowest of any solid material known.

In practice, this means parts slide against each other with minimal resistance. This translates directly to a smoother, more efficient mechanical action, whether it's the spool spinning on a fishing reel or any other rotating assembly.

Enhancing Durability and Wear Resistance

The PTFE coating acts as a durable, protective barrier between the washer and the mating surface.

This prevents direct metal-to-metal contact, which is a primary cause of galling, abrasion, and premature failure. By serving as a sacrificial, self-lubricating layer, the coating absorbs wear and tear, extending the lifespan of the more critical components.

Providing Superior Corrosion Resistance

PTFE is chemically inert, meaning it does not react with most chemicals, including saltwater, oils, and common solvents.

This property makes PTFE-coated washers an excellent choice for use in harsh environments, such as saltwater fishing, where standard metal washers would quickly succumb to corrosion.

Key Performance Characteristics to Consider

Choosing the right washer involves understanding the specific demands of your application. While PTFE is highly versatile, its performance is defined by several key characteristics.

Coefficient of Friction

This is PTFE's primary advantage. Its ultra-low friction surface minimizes the energy required to operate a mechanism, leading to improved performance and efficiency.

Operating Temperature

PTFE coatings maintain their properties across a wide temperature range. This stability ensures consistent performance whether the equipment is operating in cold or high-heat conditions generated by friction.

Load Capacity

The ability to withstand pressure is crucial. While PTFE offers good performance, the coating's thickness and the base material of the washer determine its ultimate load-bearing capacity.

Compatibility with Mating Surfaces

The smooth, non-abrasive nature of the PTFE surface ensures it will not damage the components it comes into contact with, preserving the integrity of the entire assembly.

Understanding the Trade-offs

While PTFE is an outstanding all-around choice, no single solution is perfect for every scenario. Objectivity requires acknowledging its limitations compared to other specialized materials.

Load-Carrying Limitations

For applications involving extremely high pressure or mechanical loads, a pure PTFE coating may not be the optimal choice.

In these cases, washers made from materials like bronze or filled with strengthening agents like graphite offer superior load-carrying capacity, though they typically have a higher coefficient of friction.

Coating Adhesion and Quality

The performance of a coated washer is entirely dependent on the quality of the manufacturing process.

A poorly applied coating can delaminate or wear away quickly, negating all of its benefits. Sourcing components from a reputable manufacturer is critical to ensure proper surface preparation and coating adhesion.

Alternatives for Specific Needs

Other materials exist for specific goals. For example, coatings containing molybdenum disulfide (MoS2) are often chosen for high-pressure, vacuum, or extreme temperature applications where traditional lubrication is not possible.

Making the Right Choice for Your Application

Selecting the correct thrust washer requires aligning the material's properties with your primary goal.

- If your primary focus is maximum smoothness and efficiency: A PTFE-coated washer is the ideal choice due to its unmatched low-friction properties.

- If your primary focus is durability in corrosive environments: PTFE's chemical inertness provides robust protection that significantly outperforms uncoated metal washers.

- If your primary focus is handling extreme mechanical loads: Consider a solid bronze washer or a PTFE variant filled with graphite or bronze to enhance its compressive strength.

Ultimately, choosing a PTFE-coated thrust washer is an investment in smoother performance and longer component life.

Summary Table:

| Key Benefit | Description |

|---|---|

| Low Friction | PTFE has one of the lowest coefficients of friction, ensuring smooth movement. |

| Wear Resistance | Acts as a protective barrier to prevent metal-to-metal contact and galling. |

| Corrosion Resistance | Chemically inert, ideal for harsh environments like saltwater. |

| Self-Lubricating | Reduces maintenance needs and eliminates the need for external lubricants. |

Ready to enhance your components with high-performance PTFE coatings?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom-coated thrust washers, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures you get parts that meet exact specifications, from prototypes to high-volume orders.

Contact us today to discuss how our PTFE solutions can improve your product's performance and longevity!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability