In short, PFA offers significantly higher heat resistance, while FEP provides better durability against environmental factors like water and weathering. PFA is the superior choice for applications involving repeated high-heat exposure up to 260°C (500°F). Conversely, FEP is a more resilient and cost-effective option for moderate-temperature applications where exposure to the elements is the primary concern.

The decision between PFA and FEP is a direct trade-off between thermal performance and environmental durability. PFA excels at high temperatures, whereas FEP offers a more robust and economical solution for applications exposed to moisture and weathering.

The Critical Difference: Heat Resistance

The most significant distinction between these two fluoropolymers is their ability to withstand high temperatures. This single factor often dictates which material is suitable for a given application.

PFA's High-Temperature Advantage

PFA (Perfluoroalkoxy) is specifically engineered for high-temperature service. Its upper continuous service temperature is approximately 260°C (500°F).

This makes it the preferred material for applications that involve repeated thermal cycling or consistent exposure to extreme heat, where FEP would fail.

FEP's Operating Range

FEP (Fluorinated Ethylene Propylene) has a lower maximum operating temperature, typically around 200°C (400°F).

While this is still substantial, it makes FEP unsuitable for the more demanding thermal environments where PFA thrives. FEP is an excellent choice for applications that require good chemical resistance but operate at moderate temperatures.

Environmental Durability and Exposure

Beyond heat, how these materials react to their environment is a crucial consideration, particularly in applications involving moisture or outdoor use.

FEP's Superior Weathering Resistance

FEP demonstrates better overall resistance to water and general weathering. This makes it a more reliable choice for components that will be exposed to the elements.

If your application involves high moisture or outdoor installation, FEP's material composition gives it a distinct durability advantage over PFA, provided the temperature limits are not exceeded.

PFA's Relative Vulnerability

Conversely, PFA is more affected by water and weathering than FEP. This is a critical performance trade-off to consider.

While PFA excels in controlled, high-heat industrial environments, its long-term performance can be compromised in applications with significant environmental exposure.

Chemical Resistance is (Mostly) a Tie

For most applications, chemical resistance is not the deciding factor between PFA and FEP. Both materials offer excellent, top-tier resistance to a wide range of chemicals, including aggressive bases like sodium hydroxide.

Understanding the Trade-offs

Selecting the right material requires balancing performance with other practical constraints like cost and mechanical properties.

The Cost Factor

PFA is generally more expensive than FEP. This is largely due to its higher melting point, which requires more energy and more advanced equipment to process and mold.

FEP can be injection molded at lower temperatures, making its production more economical.

Flexibility and Mechanical Properties

FEP is noticeably more flexible than PFA. This can be a critical advantage in applications like O-rings or seals that need to conform to surfaces.

In encapsulated O-rings, for example, FEP often has a higher flexibility rating, which can contribute to a better, more reliable seal in dynamic or low-pressure situations. PFA's relative rigidity is a trade-off for its superior thermal performance.

Making the Right Choice for Your Application

Your final decision should be guided by the single most critical demand of your operating environment.

- If your primary focus is high-temperature performance (above 200°C) or repeated heat cycling: PFA is the only suitable choice.

- If your primary focus is cost-effectiveness in a moderate-heat environment: FEP provides similar chemical performance for a lower price.

- If your primary focus is durability in an outdoor or high-moisture setting: FEP's superior resistance to weathering makes it the more reliable option.

- If your primary focus is seal flexibility for a conforming fit: FEP's lower rigidity gives it a distinct mechanical advantage.

By clearly defining your application's most critical need, you can confidently select the fluoropolymer that delivers the right balance of performance and value.

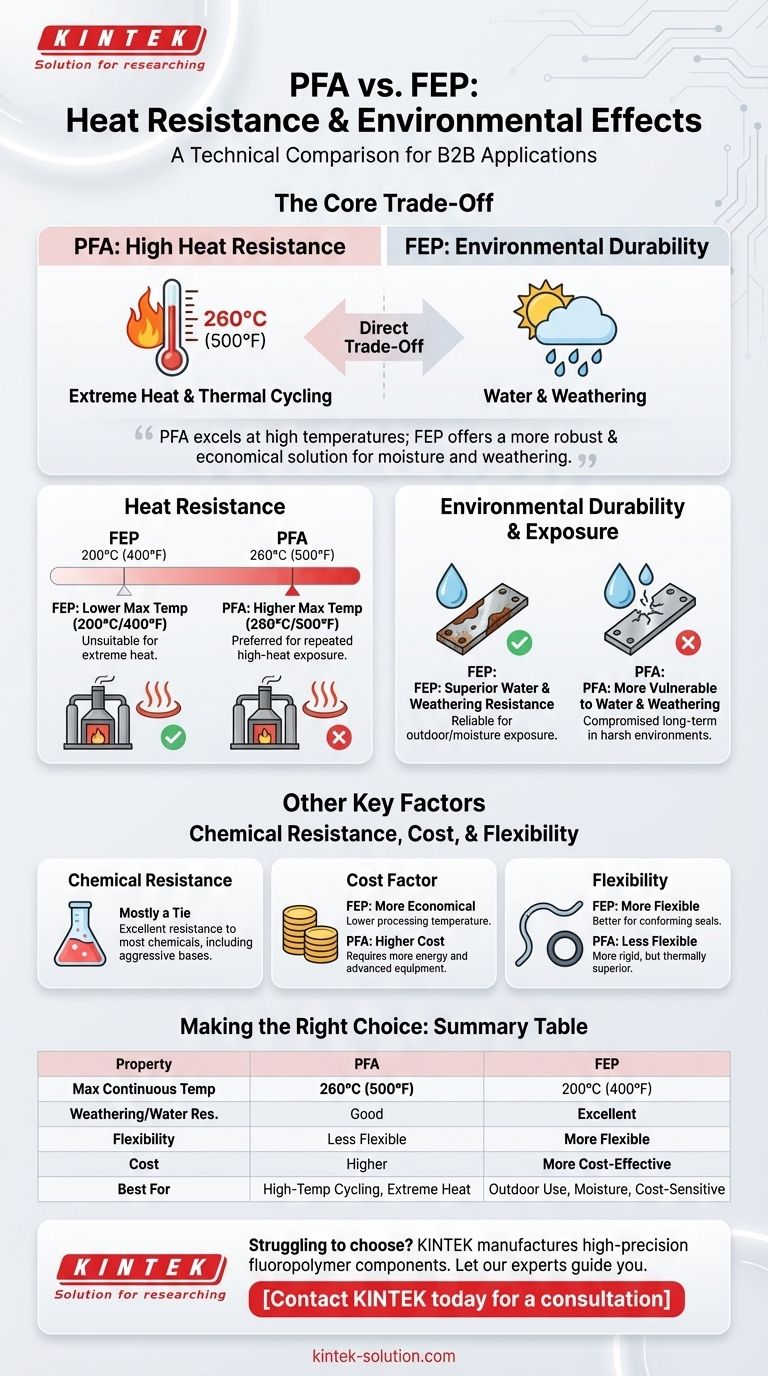

Summary Table:

| Property | PFA | FEP |

|---|---|---|

| Max Continuous Temp | 260°C (500°F) | 200°C (400°F) |

| Weathering/Water Resistance | Good | Excellent |

| Flexibility | Less Flexible | More Flexible |

| Cost | Higher | More Cost-Effective |

| Best For | High-Temp Cycling, Extreme Heat | Outdoor Use, Moisture, Cost-Sensitive Apps |

Struggling to choose between PFA and FEP for your specific application? KINTEK manufactures high-precision, custom PTFE components (including seals, liners, and labware) for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in fluoropolymers ensures you get the right material for optimal performance, temperature resistance, and durability—from prototypes to high-volume orders.

Contact KINTEK today for a consultation and let our experts guide you to the perfect solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech