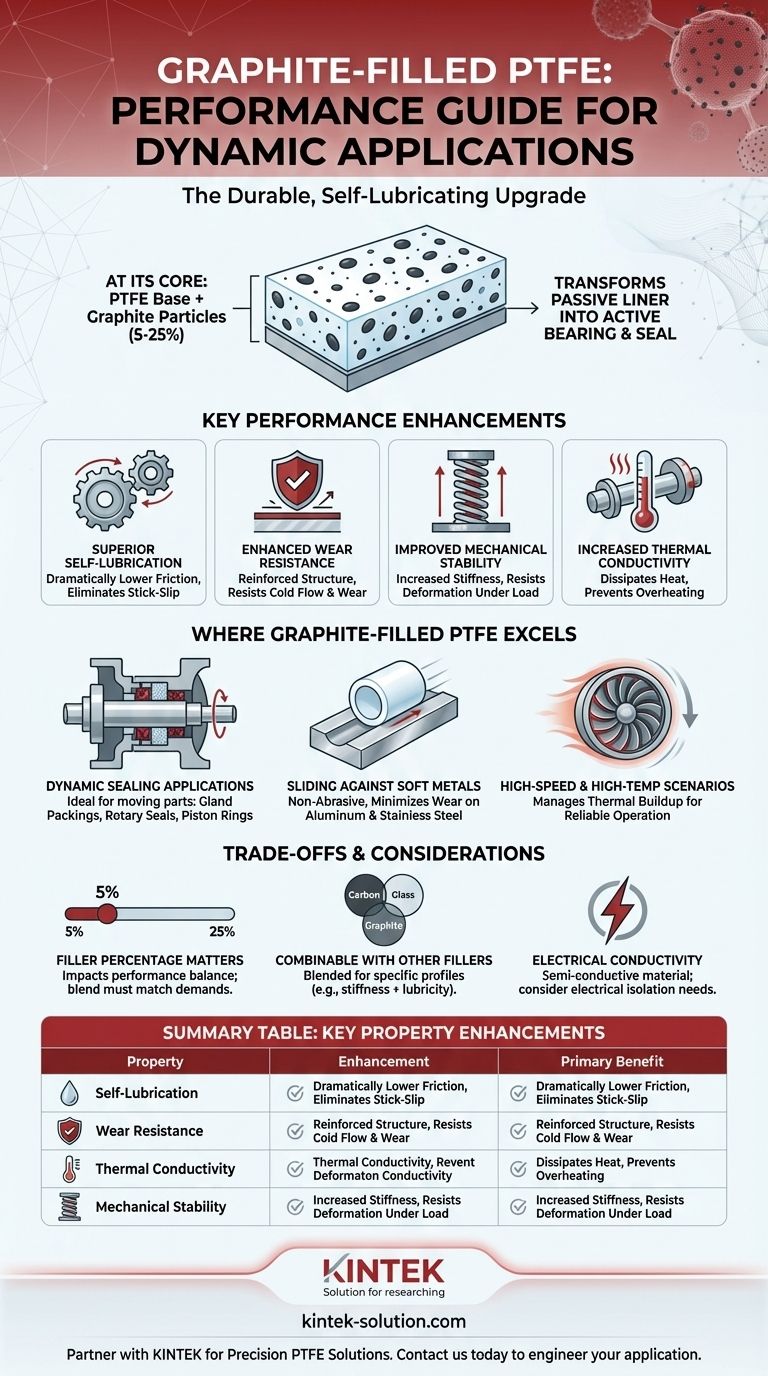

At its core, graphite-filled PTFE is a high-performance composite material engineered for demanding dynamic applications. By adding graphite particles (typically 5-25%) to a Polytetrafluoroethylene (PTFE) base, the resulting material gains superior self-lubricating properties, significantly lower friction, and enhanced wear resistance, particularly when used against softer metals.

The fundamental reason to choose graphite-filled PTFE is to overcome the limitations of virgin PTFE in applications involving motion and load. Graphite transforms the material from a passive, low-friction liner into a durable, self-lubricating bearing and sealing component that actively manages friction and heat.

Key Performance Enhancements Over Virgin PTFE

The addition of graphite is not a minor tweak; it fundamentally changes the mechanical and thermal behavior of PTFE, making it suitable for a new class of applications.

Superior Self-Lubrication and Reduced Friction

Graphite acts as a solid lubricant within the PTFE matrix. This composition provides excellent self-lubricating properties from the start, dramatically lowering the coefficient of friction.

This inherent lubricity reduces stick-slip behavior and ensures smooth, consistent motion in bearings, seals, and other sliding components.

Enhanced Wear Resistance

Virgin PTFE can be susceptible to cold flow (deformation under load) and has only moderate wear resistance.

Graphite flakes interlock within the PTFE structure, creating a more robust composite. This reinforcement significantly improves the material's resistance to wear, especially in continuous sliding applications.

Improved Mechanical Stability

The graphite filler increases the material's stiffness and compressive strength.

This means graphite-filled PTFE is better at resisting deformation under load and extrusion when used as a seal in high-pressure environments.

Increased Thermal Conductivity

A critical benefit of the graphite filler is its ability to improve thermal conductivity.

In high-speed applications like rotary shaft seals or pump packings, friction generates heat. Graphite helps conduct this heat away from the sealing surface, preventing overheating and premature failure.

Where Graphite-Filled PTFE Excels

This material is not a universal solution but is a specialized upgrade for specific, challenging environments where standard plastics would fail.

Dynamic Sealing Applications

Graphite-filled PTFE is ideal for components that move. It is commonly specified for gland packings, rotary shaft seals, and piston rings.

Its combination of low friction, wear resistance, and heat dissipation ensures a longer service life and more reliable performance in pumps, mixers, and actuators.

Sliding Against Soft Metals

A key advantage of graphite-filled PTFE is its performance against soft shaft or housing materials, such as aluminum or stainless steel.

Unlike more abrasive fillers (like glass), graphite is non-abrasive, which minimizes wear on the mating metal surface, preserving the integrity of expensive hardware.

High-Speed and High-Temperature Scenarios

The material's ability to self-lubricate and conduct heat makes it a superior choice for high-speed rotational applications.

By managing thermal buildup, it maintains its integrity and sealing capability in conditions that would cause virgin PTFE to soften and fail.

Understanding the Trade-offs and Considerations

While powerful, graphite-filled PTFE is a composite material with specific characteristics that must be understood for proper application.

The Role of Filler Percentage

The amount of graphite, typically between 5% and 25%, directly impacts performance.

Higher percentages generally improve lubricity and thermal conductivity but can affect other mechanical properties. The specific blend should be matched to the application's demands.

Combining with Other Fillers

Graphite is often used in conjunction with other fillers, such as carbon or glass, to achieve a specific performance profile.

For instance, a common blend for shaft seals is 23% carbon and 2% graphite, using the carbon for stiffness and wear resistance and the graphite for added lubricity.

Electrical Conductivity

Unlike virgin PTFE, which is an excellent electrical insulator, graphite is electrically conductive. This makes graphite-filled PTFE a semi-conductive material.

This property must be considered in any application where electrical isolation is a critical design requirement.

Making the Right Choice for Your Application

To determine if this material is the correct choice, align its strengths with your primary engineering goal.

- If your primary focus is reducing friction in a dynamic seal: Graphite-filled PTFE is an excellent choice due to its inherent self-lubricating properties.

- If your application involves sliding against soft metals like aluminum: This material is specifically engineered to improve performance and reduce wear on the mating surface.

- If you need a seal for high-speed rotating equipment: The enhanced thermal conductivity of graphite-filled PTFE helps dissipate damaging heat, preventing premature failure.

- If your goal is chemical sealing with improved durability: This composite maintains PTFE's outstanding chemical inertness while significantly boosting wear and load performance.

Ultimately, selecting graphite-filled PTFE is a strategic decision to enhance the durability and efficiency of critical moving parts.

Summary Table:

| Key Property | Enhancement Over Virgin PTFE | Primary Benefit |

|---|---|---|

| Self-Lubrication | Graphite acts as a solid lubricant | Dramatically lowers friction, eliminates stick-slip |

| Wear Resistance | Graphite flakes reinforce the PTFE matrix | Resists wear and cold flow under load |

| Thermal Conductivity | Graphite filler dissipates heat | Prevents overheating in high-speed applications |

| Mechanical Stability | Increased stiffness and compressive strength | Resists deformation and extrusion in high-pressure seals |

Need high-performance components that combine PTFE's chemical resistance with superior self-lubrication?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom graphite-filled seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures your components are optimized for wear resistance, low friction, and thermal management.

Let's engineer a solution for your demanding application. Contact our team today to discuss your project requirements, from prototypes to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials