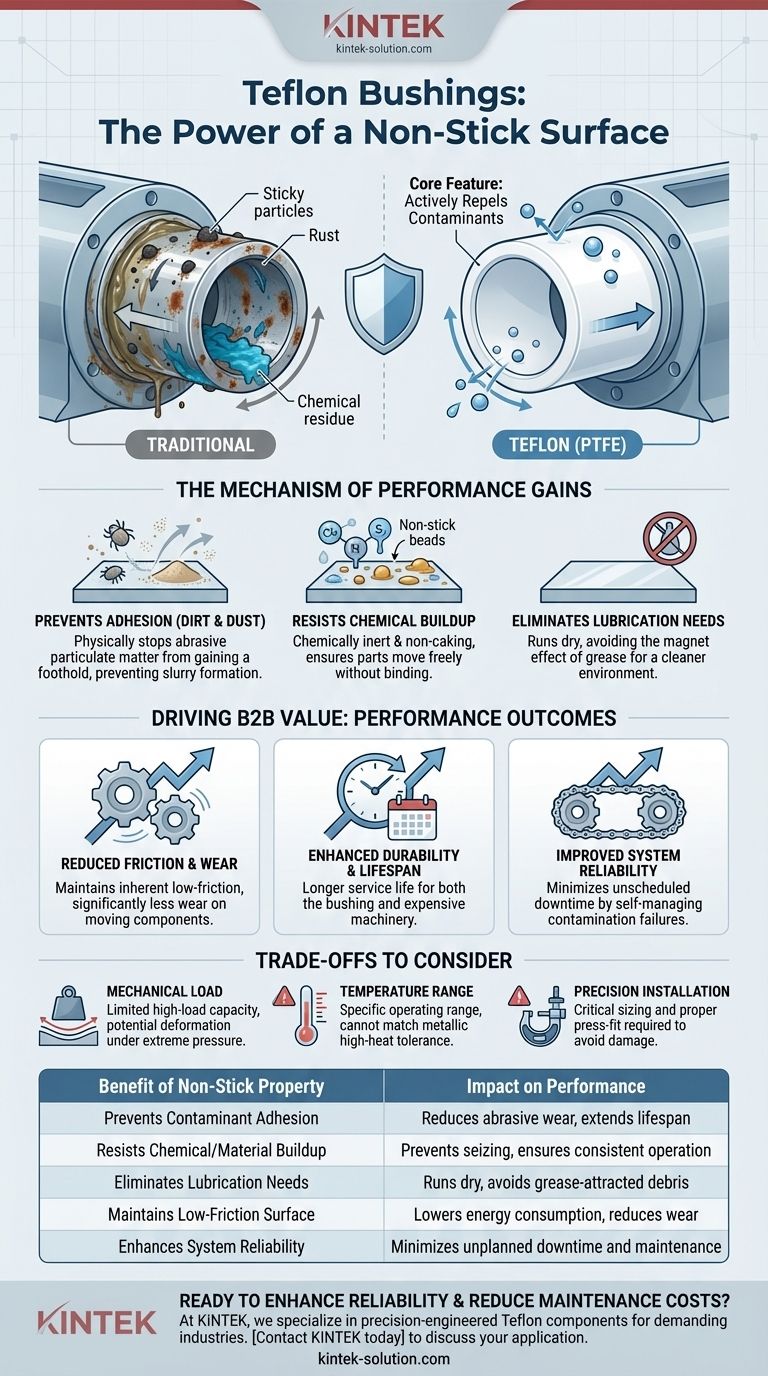

The non-stick property of Teflon bushings is a core feature that directly enhances their performance and longevity by preventing contaminants, debris, and chemicals from adhering to their surface. This self-cleaning characteristic ensures the bushing maintains its low-friction nature, protecting both itself and the machinery it serves from abrasive wear and chemical degradation.

The true benefit of Teflon's non-stick surface isn't just that things don't stick to it; it's that this property eliminates the root cause of many mechanical failures—contamination. By actively repelling buildup, it preserves the bushing's low-friction environment, drastically reducing maintenance and extending equipment life.

The Role of a Non-Stick Surface in Mechanical Systems

A bushing's primary job is to provide a low-friction surface for rotating or sliding parts. The non-stick nature of Teflon is fundamental to maintaining this ideal operating condition over time, especially in demanding environments.

Preventing Contaminant Adhesion

In many industrial settings, dust, dirt, and other particulate matter are unavoidable. When these contaminants stick to a lubricated surface, they can form an abrasive slurry that accelerates wear.

Teflon’s non-stick surface physically prevents these particles from gaining a foothold. This keeps the operating environment clean, preserving the integrity of both the bushing and the shaft.

Resisting Chemical and Material Buildup

In applications involving chemicals or sticky materials, buildup on component surfaces can seize machinery. Teflon is not only chemically inert but also resists the adhesion of process materials.

This ensures that parts move freely without the caking and binding that can plague other materials, leading to more reliable and consistent system performance.

Eliminating Traditional Lubrication Needs

A key advantage of Teflon is its exceptionally low coefficient of friction, which often eliminates the need for oil or grease. This is directly supported by its non-stick nature.

Traditional wet lubricants are often magnets for dirt and debris. Because Teflon bushings run dry, their non-stick surface ensures they remain clean and free of the abrasive paste that can form in greased joints.

How Non-Stick Properties Drive Performance Gains

The ability to repel contaminants translates directly into tangible benefits for the machinery, including reduced costs, less downtime, and greater overall reliability.

Radically Reduced Friction and Wear

A clean surface is a low-friction surface. By preventing abrasive particles from sticking, the non-stick property ensures that the bushing's inherent low-friction nature is maintained throughout its service life.

This leads to significantly less wear and tear on moving components, which is critical in high-speed or continuous-use equipment.

Enhanced Durability and Equipment Lifespan

By resisting both abrasive wear from particulate matter and degradation from corrosive chemicals, the bushing is fundamentally more durable.

This extends not only the life of the bushing itself but also the lifespan of the more expensive machinery it is part of, reducing the frequency of costly replacements.

Improved System Reliability

Mechanical failures are often caused by unexpected seizure or degradation from contamination. A system using Teflon bushings is inherently more reliable because it self-manages a major failure vector.

This results in less unscheduled downtime, a crucial factor in production and material handling environments where every minute of operation counts.

Understanding the Trade-offs

While highly effective, Teflon's properties come with considerations that are essential for proper application. Its unique strengths are balanced by specific limitations.

Mechanical Load and Pressure

Teflon (PTFE) is a relatively soft polymer. While its non-stick and low-friction qualities are superb, it is not always suitable for extremely high-load applications where it may deform or "creep" under constant, intense pressure.

Operating Temperature Range

Teflon offers good thermal stability within a specific range. However, it cannot match the extreme high-temperature tolerance of metallic bushings. Exceeding its thermal limits can lead to material failure.

Design and Installation Precision

Due to its softness, proper sizing and installation are critical. An improper press-fit or insufficient clearance can damage the bushing or compromise its performance, negating its benefits.

Making the Right Choice for Your Application

Selecting the right bushing material depends entirely on the primary challenge you need to solve. Teflon's non-stick properties make it a superior choice for specific, common problems.

- If your primary focus is reducing maintenance in a dirty environment: The non-stick property is your greatest asset, as it prevents the buildup of abrasive contaminants that require frequent cleaning.

- If your primary focus is reliability in a chemical processing application: The combination of non-stick and chemically inert properties ensures consistent performance by preventing material caking and corrosion.

- If your primary focus is efficiency in continuous-use machinery: The low-friction surface, kept clean by its non-stick nature, minimizes wear and eliminates the need for lubrication, directly reducing operational downtime.

Ultimately, understanding that Teflon's non-stick quality is a mechanism for maintaining a clean, low-friction system allows you to deploy it where it will have the greatest impact on reliability and cost.

Summary Table:

| Benefit of Non-Stick Property | Impact on Performance |

|---|---|

| Prevents Contaminant Adhesion | Reduces abrasive wear, extends lifespan |

| Resists Chemical/Material Buildup | Prevents seizing, ensures consistent operation |

| Eliminates Lubrication Needs | Runs dry, avoids grease-attracted debris |

| Maintains Low-Friction Surface | Lowers energy consumption, reduces wear |

| Enhances System Reliability | Minimizes unplanned downtime and maintenance |

Ready to enhance your equipment's reliability and reduce maintenance costs?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom bushings, seals, and liners. Our precision-engineered Teflon parts are designed to deliver the non-stick, low-friction, and chemical-resistant benefits detailed above, ensuring your machinery operates efficiently in the most demanding environments.

We serve a wide range of specialized industries, including semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our team is equipped to provide custom fabrication solutions that meet your exact specifications.

Contact KINTEK today to discuss your application requirements and discover how our PTFE solutions can solve your specific challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability