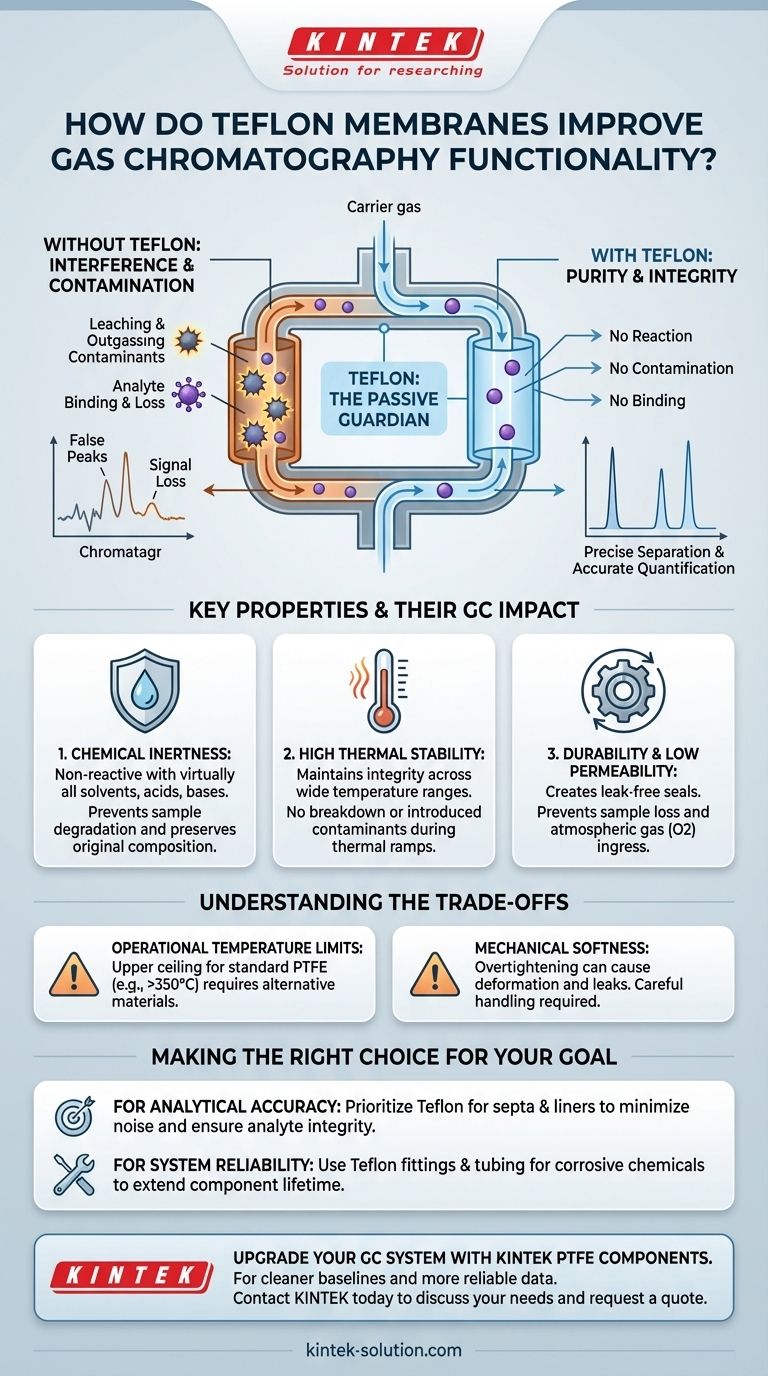

In gas chromatography, Teflon membranes are critical because they ensure the purity and integrity of the sample as it moves through the system. Their primary function is to provide a chemically inert and stable pathway, which prevents the equipment itself from interfering with the measurement. This non-reactive quality is essential for achieving the precise separation and accurate quantification that gas chromatography (GC) is known for.

The core value of Teflon in gas chromatography is not that it actively participates in the separation, but that it passively resists interaction. Its profound chemical inertness ensures the data reflects the sample alone, free from contamination or reaction with the instrument components.

The Role of Material Integrity in Analysis

In a high-precision technique like gas chromatography, every component that contacts the sample can influence the final result. The goal is to measure the sample, not the system's interaction with the sample. This is where the choice of material becomes paramount.

Preventing Sample Contamination

Many materials can "leach" or "outgas" trace amounts of chemicals, especially when heated. These contaminants can travel with the carrier gas, creating false peaks in the chromatogram or raising the baseline noise, which obscures the detection of low-concentration analytes. Teflon's stability prevents this.

Ensuring Analyte Integrity

Conversely, reactive materials can bind to or chemically alter the compounds you are trying to measure (the analytes). This leads to sample loss and inaccurate quantification, as a portion of the analyte never reaches the detector. Teflon’s inertness ensures the analytes pass through the system unchanged.

Key Properties of Teflon and Their GC Impact

Teflon's effectiveness stems from a unique combination of physical and chemical properties that are ideally suited for the demands of a GC system.

Exceptional Chemical Inertness

This is Teflon's most critical feature. It is non-reactive with virtually all solvents, acids, bases, and organic compounds used in GC. This means it will not degrade from contact with harsh samples, nor will it react with sensitive analytes, preserving the original chemical composition of the sample.

High Thermal Stability

Gas chromatography operates at high temperatures, particularly in the injection port and column oven. Teflon maintains its structural integrity and chemical inertness across a wide operational temperature range, ensuring it doesn't break down and introduce contaminants into the system during a thermal ramp.

Durability and Low Permeability

Teflon is a robust material that creates reliable, leak-free seals in fittings and septa. Its low permeability prevents the sample from being lost through absorption into the material and stops atmospheric gases like oxygen from leaking into the system, which could degrade the column or interfere with certain detectors.

Understanding the Trade-offs

While highly effective, Teflon is not a universal solution for every possible scenario. An expert understands the material's operational boundaries.

Operational Temperature Limits

Although thermally stable, standard Teflon (PTFE) has an upper temperature ceiling. For GC applications running at extremely high temperatures (e.g., above 350°C), other materials like graphite or specialized polyimides are often required for components like ferrules or septa to avoid thermal degradation.

Mechanical Softness

Teflon is a relatively soft polymer. This quality is excellent for creating tight seals, but it also means that fittings can be permanently deformed if over-tightened. Overtightening can damage the component and ultimately create a leak, compromising the entire system.

Making the Right Choice for Your Goal

Integrating Teflon components into your GC system is a strategic decision to enhance data quality and system robustness.

- If your primary focus is analytical accuracy: Prioritize Teflon or Teflon-coated components (like septa and liners) to minimize baseline noise, eliminate ghost peaks from contamination, and ensure analyte integrity.

- If your primary focus is system reliability: Use Teflon for fittings and transfer tubing when working with corrosive or reactive chemicals to extend component lifetime and reduce the frequency of maintenance.

Ultimately, leveraging Teflon in your GC setup is a foundational step toward achieving clean, trustworthy, and repeatable analytical data.

Summary Table:

| Key Property | Benefit in Gas Chromatography |

|---|---|

| Chemical Inertness | Prevents sample contamination and analyte reaction for accurate quantification. |

| High Thermal Stability | Maintains integrity at high temperatures, preventing breakdown and contamination. |

| Low Permeability & Durability | Creates reliable, leak-free seals and prevents sample loss or air ingress. |

Upgrade your GC system's performance with precision-engineered PTFE components from KINTEK.

For analytical chemists and lab managers in the semiconductor, medical, and laboratory industries, even minor contamination can compromise data integrity. KINTEK specializes in manufacturing high-purity PTFE seals, liners, transfer lines, and custom labware designed specifically for the demanding environments of gas chromatography and other analytical applications.

By choosing KINTEK, you benefit from:

- Enhanced Data Accuracy: Our chemically inert PTFE components eliminate ghost peaks and baseline noise, ensuring your results reflect your sample alone.

- Increased System Uptime: Durable, reliable parts reduce maintenance frequency and prevent costly downtime.

- Custom Fabrication: We work with you from prototype to high-volume production to create components that perfectly fit your unique application and instrumentation.

Ready to achieve cleaner baselines and more reliable data? Contact KINTEK today to discuss your specific needs and request a quote for precision PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability