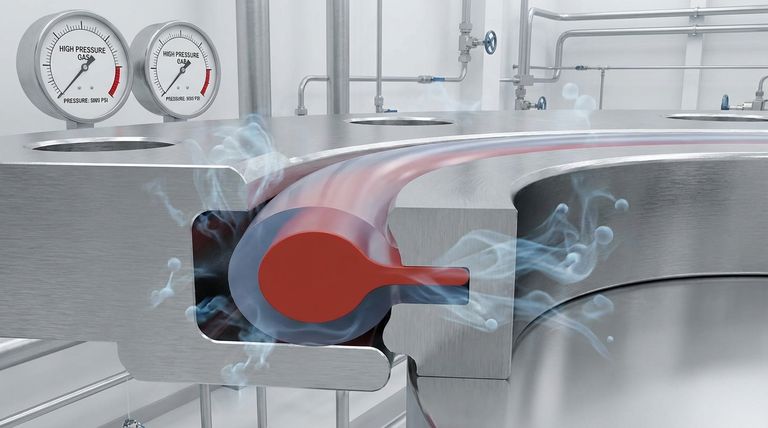

In high-pressure gas applications, sealing reliability is paramount. Teflon encapsulated O-rings are highly effective in these conditions due to their unique two-part construction. The seamless Teflon (FEP or PFA) jacket provides an exceptional barrier against gas permeation, while the inner elastomer core provides the constant energizing force needed to maintain a tight seal.

The core advantage of a Teflon encapsulated O-ring is its ability to combine the low gas permeability of a rigid plastic with the flexibility and memory of a rubber elastomer. This creates a seal that effectively prevents the slow, persistent leaks common with standard rubber O-rings under high gas pressure.

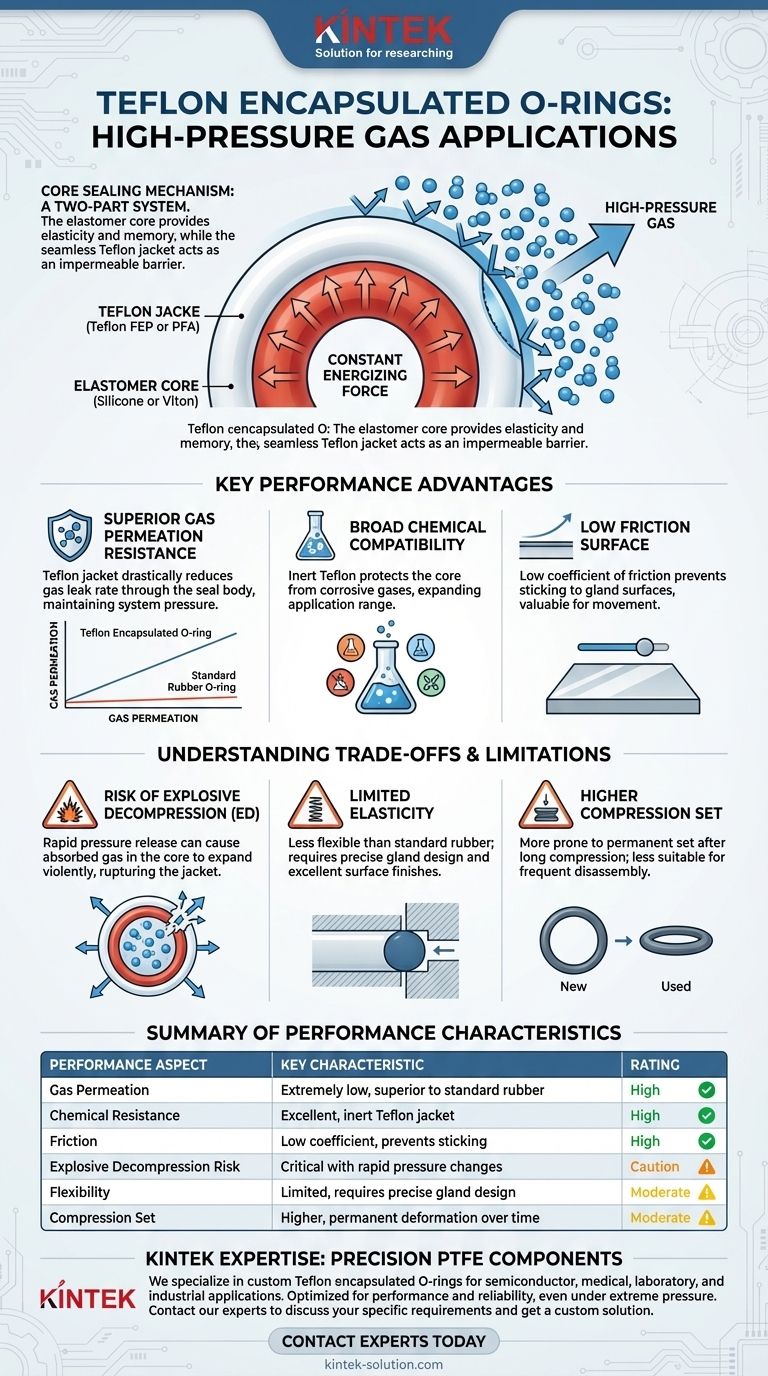

The Core Sealing Mechanism: A Two-Part System

To understand the performance of these seals, you must first understand their components. They are not a homogenous material but a composite system where each part plays a distinct, critical role.

The Elastomer Core: Providing the Force

The internal ring, typically made of Silicone or Viton (FKM), acts as the "engine" of the seal. Its purpose is to provide elasticity and memory.

When compressed in a gland, this core constantly pushes outward against the rigid Teflon jacket, ensuring it remains in firm contact with the sealing surfaces.

The Teflon Jacket: The Impermeable Barrier

The seamless outer jacket, made from FEP or PFA Teflon, is the component that faces the high-pressure gas. Its primary role is to act as a protective and impermeable barrier.

This jacket is defined by its extremely low gas permeation rate. Unlike standard elastomers, which can absorb gas and allow it to slowly pass through, the dense molecular structure of Teflon makes it exceptionally difficult for gas molecules to penetrate.

Key Performance Advantages in High-Pressure Gas

The dual-component design gives these O-rings specific advantages that make them suitable for challenging gas sealing duties.

Superior Gas Permeation Resistance

This is the single most important characteristic for high-pressure gas service. The Teflon jacket drastically reduces the rate at which gas can leak through the body of the seal itself, ensuring system pressure is maintained over long periods.

Broad Chemical Compatibility

The Teflon jacket is almost universally inert. This protects the more sensitive inner elastomer core from potentially corrosive or reactive gases, significantly expanding the range of applications where the seal can be used safely.

Low Friction Surface

The low coefficient of friction of Teflon prevents the O-ring from sticking to gland surfaces. While less critical in static seals, this is a valuable property in any application that requires occasional movement or low breakaway force.

Understanding the Trade-offs and Limitations

No sealing solution is perfect. While highly effective, Teflon encapsulated O-rings have specific limitations that must be accounted for in the design phase to prevent seal failure.

Risk of Explosive Decompression (ED)

This is a critical failure mode in high-pressure gas systems. Over time, high-pressure gas can slowly permeate the Teflon jacket and be absorbed by the elastomer core. If the system pressure is suddenly released, this trapped gas expands violently, rupturing the Teflon jacket from the inside out and causing total seal failure.

Limited Elasticity

The rigid Teflon jacket gives the O-ring much less flexibility than a standard rubber seal. This means it requires more force to compress and is less forgiving of imperfections in the sealing surfaces. Proper gland design and excellent surface finishes are mandatory.

Higher Compression Set

Because the Teflon jacket is not truly elastic, these O-rings are more prone to taking a permanent "set" after being compressed for a long time. This makes them less suitable for applications that require frequent disassembly and reassembly, as the seal may not rebound to effectively fill the gland a second time.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its properties to the demands of the system.

- If your primary focus is a static, stable high-pressure system: Teflon encapsulated O-rings offer excellent long-term performance and minimal leakage due to their low gas permeation.

- If your application involves rapid pressure cycling or frequent venting: You must carefully evaluate the risk of Explosive Decompression (ED) and may need to specify materials designed to resist it.

- If your design requires frequent assembly and disassembly: Be mindful of the seal's higher compression set and the potential for installation damage to the Teflon jacket.

By understanding both its unique strengths and critical limitations, you can confidently specify a Teflon encapsulated O-ring for reliable high-pressure gas sealing.

Summary Table:

| Performance Aspect | Key Characteristic |

|---|---|

| Gas Permeation | Extremely low, superior to standard rubber O-rings |

| Chemical Resistance | Excellent, due to inert Teflon (FEP/PFA) jacket |

| Friction | Low coefficient, prevents sticking |

| Key Limitation | Risk of Explosive Decompression (ED) with rapid pressure changes |

| Flexibility | Limited; requires precise gland design and surface finish |

Need a reliable, high-performance seal for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom Teflon encapsulated O-rings. We understand the critical balance of low gas permeation, chemical resistance, and mechanical strength required for semiconductor, medical, laboratory, and industrial applications.

Our team works with you from prototype to high-volume production to ensure your sealing solution is optimized for performance and reliability, even under extreme pressure.

Contact our experts today to discuss your specific requirements and get a custom solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability