In short, standard PTFE is rigid and dense, while expanded PTFE is soft, highly flexible, and compressible. This fundamental difference stems from their manufacturing process. Standard PTFE is a solid material, whereas expanded PTFE is processed to create a porous, web-like internal structure, giving it a sponge-like quality.

The core decision between standard and expanded PTFE gaskets is a function of your flange condition. Standard PTFE's rigidity is suited for perfect, high-pressure surfaces, while expanded PTFE's soft, compressible nature is designed to create a reliable seal on irregular or delicate surfaces.

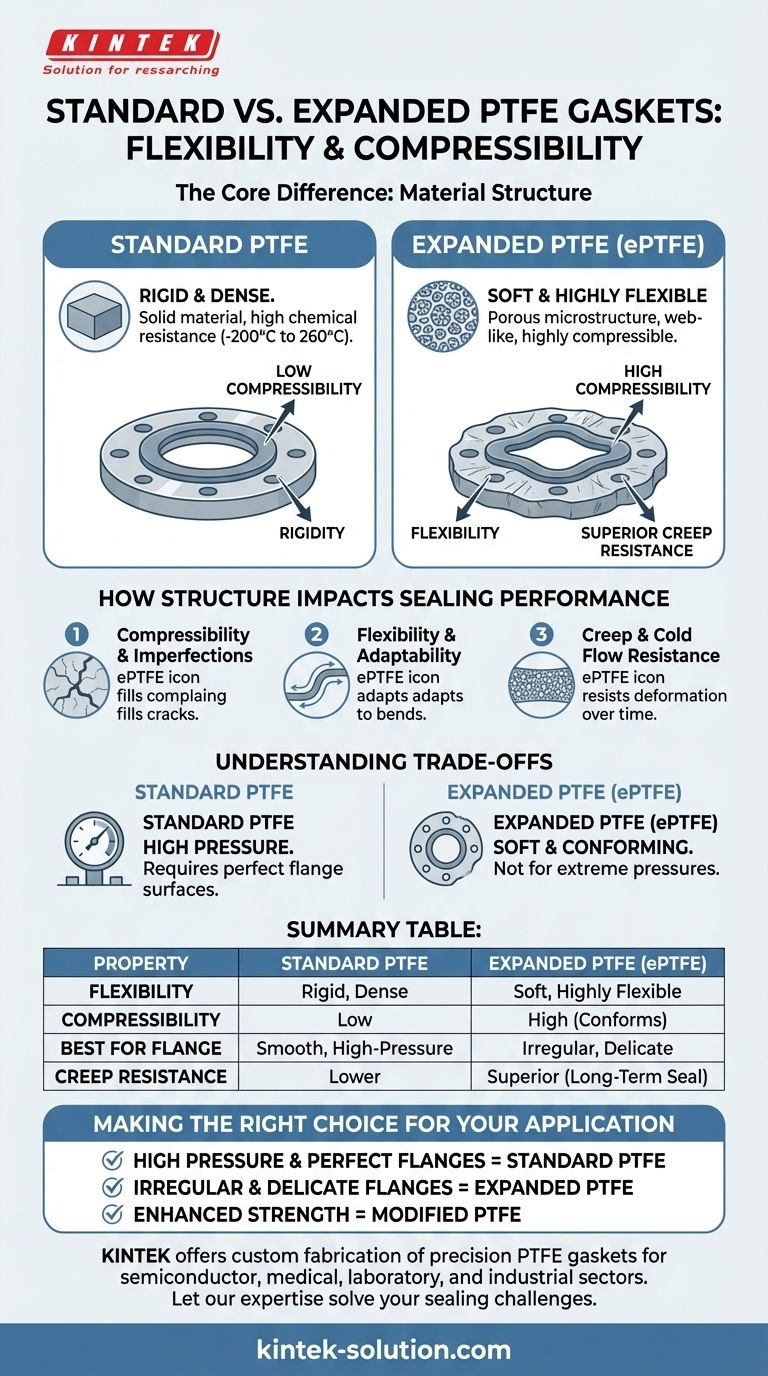

The Core Difference: Material Structure

The properties of flexibility and compressibility are a direct result of how each material is constructed at a microscopic level.

Standard PTFE: A Solid, Rigid Material

Standard Polytetrafluoroethylene (PTFE) is a solid polymer. Think of it as a solid, dense block of plastic.

This structure gives it its characteristic rigidity and durability. It has excellent chemical resistance and can handle a wide temperature range, from -200°C to 260°C (-328°F to 500°F).

Expanded PTFE (ePTFE): A Porous, Flexible Network

Expanded PTFE (ePTFE) starts as standard PTFE but undergoes a special expansion process. This creates a porous microstructure of fibers and nodes.

This internal network is what makes ePTFE exceptionally soft, flexible, and compressible, unlike its solid counterpart.

How Structure Impacts Sealing Performance

The difference in internal structure directly translates to how each gasket performs in a real-world application, especially when dealing with less-than-perfect conditions.

Compressibility: The Key to Imperfect Surfaces

Because ePTFE is soft and porous, it compresses easily under load.

This high compressibility allows it to conform and fill in minor imperfections, scratches, or irregularities on a flange face, ensuring a tight seal where a rigid gasket might fail.

Flexibility and Adaptability

The flexible nature of ePTFE makes it easier to handle and install, especially on complex or large flanges.

It can also better compensate for flange deformation that might occur due to temperature fluctuations or pressure changes, maintaining a consistent seal.

Superior Creep and Cold Flow Resistance

Creep, or cold flow, is the tendency of a material to slowly deform over time when under constant pressure.

Despite its softness, the fibrous structure of ePTFE gives it excellent resistance to creep. It maintains its shape and sealing pressure far better than standard PTFE, leading to a more durable, long-lasting seal.

Understanding the Trade-offs

Choosing a material always involves balancing its strengths and weaknesses for a specific job.

Pressure Limitations of ePTFE

The primary trade-off for ePTFE's softness and compressibility is its performance in very high-pressure applications.

Its porous structure is not as resistant to extreme pressures as the solid, dense body of a standard PTFE gasket.

The Rigidity Advantage of Standard PTFE

Standard PTFE's rigidity and durability make it a reliable choice for high-pressure systems, provided the flange surfaces are smooth, parallel, and in excellent condition.

Its solid structure provides the mechanical strength needed to withstand high bolt loads and internal pressures without being crushed.

The "Modified PTFE" Alternative

Modified PTFE gaskets bridge the gap between standard and expanded versions.

By adding fillers like glass fiber or graphite powder, manufacturers can improve the strength, durability, and creep resistance of standard PTFE while retaining its core chemical properties.

Making the Right Choice for Your Application

Your flange condition and operating parameters should dictate your gasket choice.

- If your primary focus is high-pressure sealing with perfect flanges: Standard PTFE's rigidity and durability offer a reliable solution.

- If your primary focus is sealing older, irregular, or delicate flanges: Expanded PTFE's superior compressibility and flexibility will create a more effective and reliable seal.

- If your primary focus is improving upon standard PTFE's performance: A modified PTFE gasket can offer enhanced strength and durability for demanding applications.

Ultimately, a successful seal depends on choosing the gasket material that best conforms to the specific conditions of your equipment.

Summary Table:

| Property | Standard PTFE | Expanded PTFE (ePTFE) |

|---|---|---|

| Flexibility | Rigid and dense | Soft and highly flexible |

| Compressibility | Low | High (conforms to imperfections) |

| Best For Flange Type | Smooth, parallel, high-pressure | Irregular, scratched, or delicate |

| Creep/Cold Flow Resistance | Lower | Superior (maintains seal long-term) |

Struggling to achieve a reliable seal on your equipment? The right PTFE gasket is critical for performance and safety. KINTEK manufactures precision PTFE components, including standard, expanded (ePTFE), and modified PTFE gaskets, for the semiconductor, medical, laboratory, and industrial sectors. We provide custom fabrication from prototypes to high-volume orders to ensure a perfect seal for your specific flange conditions and operating parameters.

Contact KINTEK today for a consultation and let our expertise solve your sealing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection