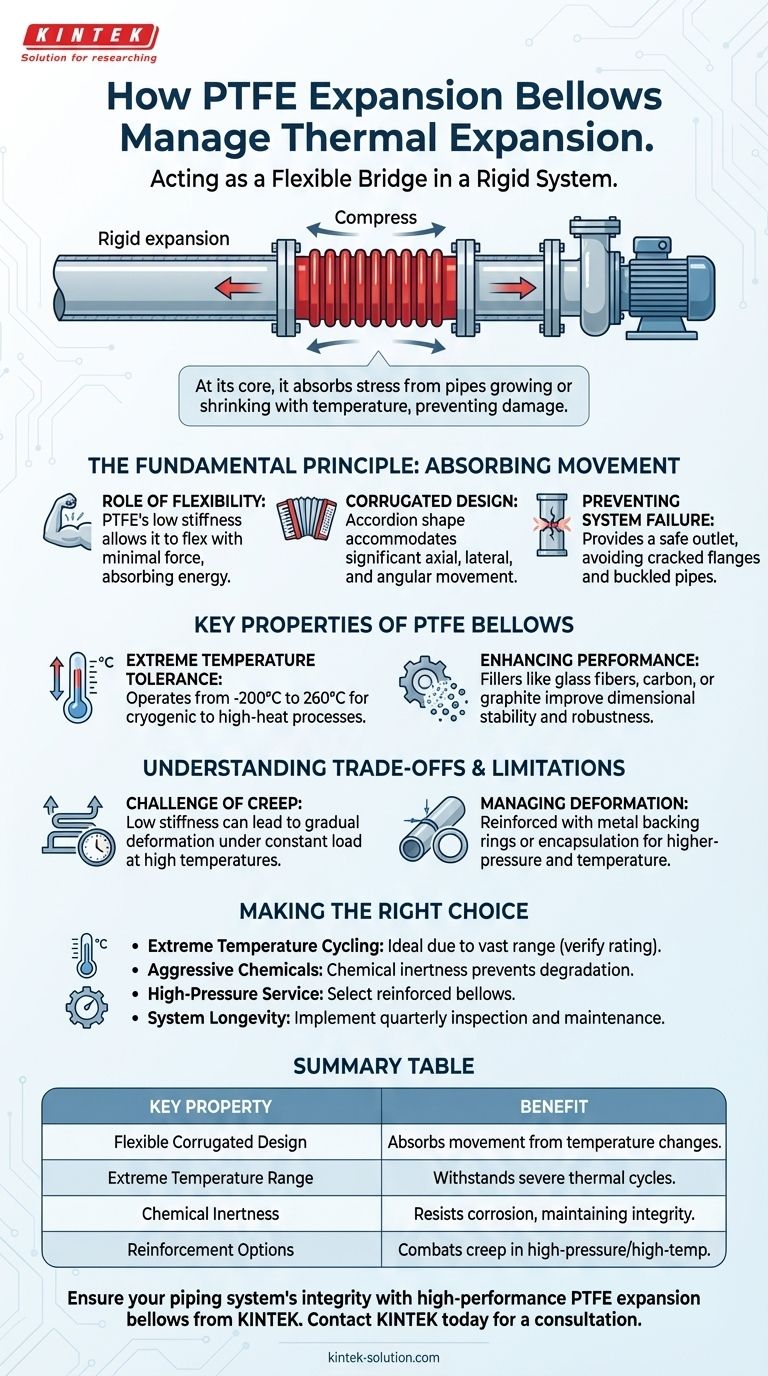

At its core, a PTFE expansion bellow manages thermal expansion by acting as a flexible bridge in a rigid system. It absorbs the stress from pipes that grow or shrink with temperature changes. The bellow's accordion-like design allows it to compress, extend, and flex, preventing the immense forces of thermal expansion from cracking pipes or causing leaks at connection points.

The fundamental challenge in any piping system is not to prevent thermal expansion, but to safely accommodate the movement it creates. PTFE expansion bellows solve this by isolating rigid components from stress, leveraging the material's unique combination of flexibility and extreme temperature resistance.

The Fundamental Principle: Absorbing Movement

PTFE bellows are engineered to be the designated point of movement in a pipeline. They intentionally introduce a flexible element that can safely deform, protecting the rest of the system.

The Role of Flexibility

PTFE is a polymer with inherently low stiffness. This property allows the bellow to flex and move with minimal force, absorbing energy that would otherwise be transferred to the pipes and equipment.

The Corrugated Design

The bellow's signature accordion-like shape is critical. This geometry allows a small component to accommodate significant changes in length (axial movement), shifts in position (lateral movement), or changes in angle (angular movement).

Preventing System Failure

Without a flexible joint, a pipe that expands due to heat has nowhere to go. This builds up immense internal stress, which can lead to catastrophic failures like cracked flanges, buckled pipes, or damaged equipment nozzles. The bellow provides a safe outlet for this movement.

Key Properties of PTFE Bellows

The choice of PTFE is not arbitrary; its specific material properties make it exceptionally well-suited for managing thermal dynamics in demanding environments.

Extreme Temperature Tolerance

PTFE can operate effectively across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F). This makes it suitable for everything from cryogenic applications to high-temperature sterilization processes in the pharmaceutical industry.

Enhancing Performance with Fillers

Standard PTFE can be modified to improve its mechanical properties. Adding fillers like glass fibers, carbon, or graphite enhances dimensional stability and thermal performance, making the bellows more robust in specific temperature or pressure conditions.

Understanding the Trade-offs and Limitations

While highly effective, PTFE bellows have inherent limitations that must be understood and managed to ensure system reliability.

The Challenge of Creep

PTFE's low stiffness and high thermal expansion mean it can be susceptible to creep—a slow, gradual deformation when held under a constant load, especially at elevated temperatures.

Managing Deformation

To counteract creep in higher-pressure or high-temperature applications, PTFE bellows are often reinforced. Methods include using metal backing rings or full encapsulation to provide external structural support without sacrificing flexibility.

The Need for Proper Maintenance

Reliability depends on proactive care. A routine maintenance schedule should include quarterly visual inspections for any signs of cracking, chemical attack, or deformation. The surface should be kept clean with non-abrasive agents.

Making the Right Choice for Your System

Selecting the appropriate expansion bellow requires matching its capabilities to your system's specific demands.

- If your primary focus is extreme temperature cycling: A PTFE bellow is an ideal choice due to its vast operating range, but verify its rating for the full temperature swing.

- If your primary focus is handling aggressive chemicals: PTFE's chemical inertness is a major advantage, ensuring the bellow will not degrade from contact with corrosive media.

- If your primary focus is high-pressure service: Select a reinforced bellow with external backing rings or encapsulation to prevent deformation and creep under sustained load.

- If your primary focus is system longevity: Implement a strict quarterly inspection and maintenance schedule to identify and address potential issues before they lead to failure.

By understanding both its strengths and limitations, you can effectively leverage PTFE expansion bellows to ensure the integrity and safety of your critical piping systems.

Summary Table:

| Key Property | Benefit for Managing Thermal Expansion |

|---|---|

| Flexible Corrugated Design | Absorbs axial, lateral, and angular movement from temperature changes. |

| Extreme Temperature Range (-200°C to 260°C) | Withstands severe thermal cycles from cryogenic to high-heat processes. |

| Chemical Inertness | Resists corrosion from aggressive media, maintaining integrity. |

| Reinforcement Options | Backing rings or encapsulation combat creep in high-pressure/high-temperature applications. |

Ensure your piping system's integrity with high-performance PTFE expansion bellows from KINTEK.

Whether you're in the semiconductor, pharmaceutical, laboratory, or industrial sector, our bellows are precision-engineered to manage thermal expansion, absorb stress, and prevent costly failures. We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today for a consultation and let our experts help you select the perfect bellow for your temperature, pressure, and chemical requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability