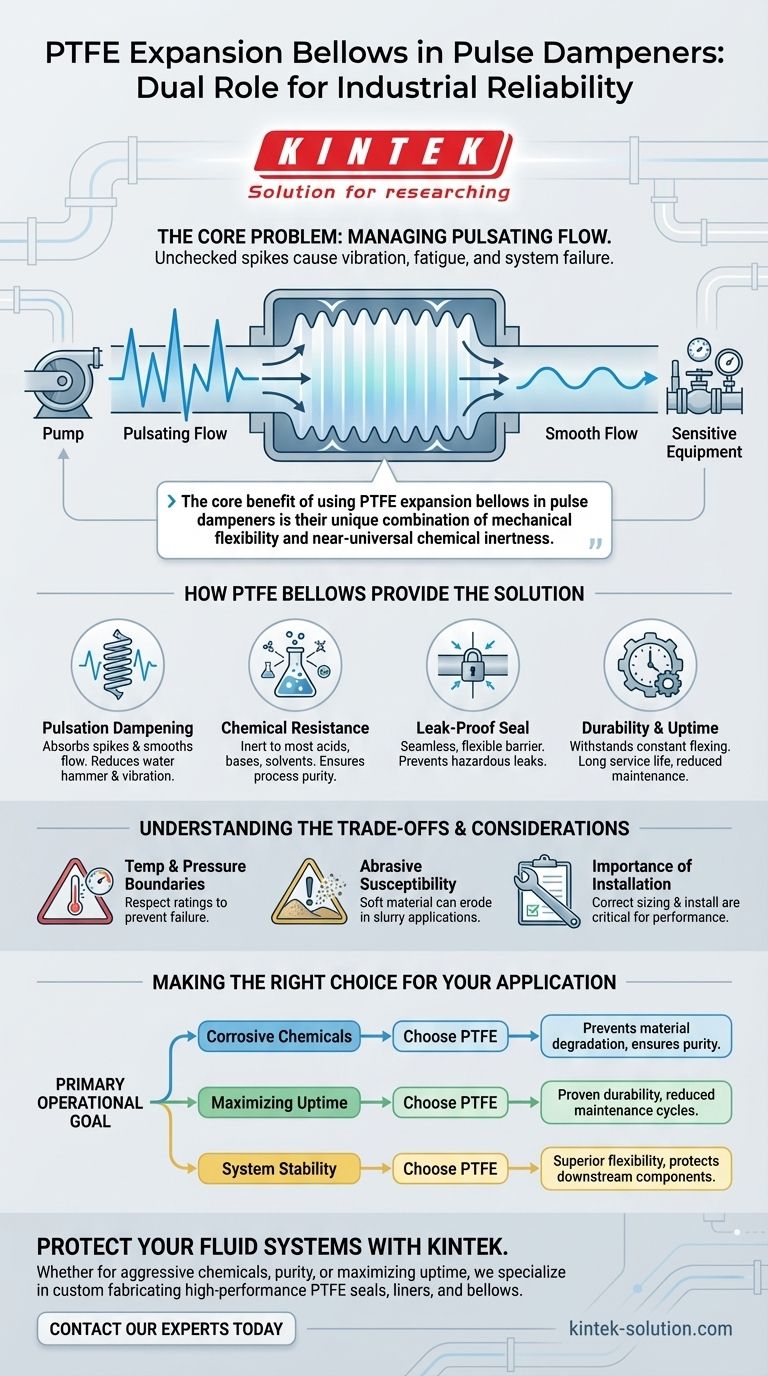

In industrial pulse dampeners, PTFE expansion bellows serve a critical dual role: they physically absorb and smooth out damaging pressure surges while providing exceptional resistance to chemical attack, thereby ensuring both operational stability and long-term system reliability.

The core benefit of using PTFE expansion bellows in pulse dampeners is their unique combination of mechanical flexibility and near-universal chemical inertness. This allows them to protect sensitive equipment from both destructive pressure spikes and corrosive media, a crucial advantage in demanding industrial environments.

The Core Problem: Managing Pulsating Flow

Industrial fluid systems, especially those using positive displacement pumps like diaphragm or piston pumps, do not produce a smooth, consistent stream. They create a series of pressure waves or pulses.

The Source of Pulsation

These pumps work by repeatedly trapping and discharging a fixed volume of fluid. This action inherently creates high-pressure surges followed by low-pressure troughs, resulting in a pulsating flow.

The Impact of Unchecked Pressure Spikes

If left unmanaged, these pressure fluctuations can cause significant problems. They lead to pipeline vibration (water hammer), premature fatigue of valves and fittings, inaccurate readings from pressure gauges, and ultimately, an increased risk of leaks or system failure.

How PTFE Bellows Provide the Solution

A pulse dampener is designed to absorb this unwanted energy. The PTFE expansion bellow is the critical component inside the dampener that makes this possible with unparalleled reliability.

The Mechanism of Fluctuation Absorption

The flexible, accordion-like structure of the PTFE bellow allows it to expand and contract in response to pressure changes. During a pressure spike, the bellow compresses, absorbing the pulse's energy. In the subsequent trough, it expands, releasing the fluid and smoothing the flow downstream.

The Material Advantage: Chemical Inertness

PTFE is renowned for being chemically inert to nearly all industrial chemicals, acids, and bases. This means the bellow will not corrode, degrade, or leach contaminants into the process fluid, making it ideal for applications in chemical processing, pharmaceuticals, and food production.

The Durability Factor: Long-Term Reliability

The inherent durability of PTFE ensures a long service life even under constant flexing. This characteristic drastically reduces the need for frequent maintenance and minimizes costly operational downtime associated with component replacement.

Ensuring a Tight, Leak-Proof System

The bellow itself acts as a seamless, flexible barrier. This design ensures a tight, leak-proof seal within the pulse dampener, which is essential for maintaining system efficiency and preventing the escape of hazardous materials.

Understanding the Trade-offs and Considerations

While highly effective, PTFE bellows are not a universal solution. An objective assessment requires understanding their operational limits.

Temperature and Pressure Boundaries

PTFE has specific temperature and pressure ratings that must be respected. Exceeding these limits can lead to material degradation or mechanical failure. Always verify that the component specifications match the system's operating conditions.

Susceptibility to Abrasives

PTFE is a relatively soft material. In applications with highly abrasive slurries or particulates, the bellow can be susceptible to erosion over time, which may shorten its service life.

Importance of Correct Installation

The performance of a PTFE bellow is highly dependent on proper installation and sizing. An incorrectly specified or installed bellow can fail prematurely or fail to dampen pulsations effectively.

Making the Right Choice for Your Application

Selecting the right component is about matching its strengths to your primary operational goal.

- If your primary focus is handling highly corrosive chemicals: PTFE is the default choice due to its near-universal chemical resistance, which prevents material degradation and ensures process purity.

- If your primary focus is maximizing system uptime: The proven durability and long service life of PTFE bellows directly translate to reduced maintenance cycles and minimized operational downtime.

- If your primary focus is system stability and equipment protection: The superior flexibility of PTFE bellows effectively absorbs pressure fluctuations, safeguarding downstream components from damaging vibration and fatigue.

Ultimately, selecting PTFE expansion bellows for pulse dampening is a strategic decision to enhance the integrity, safety, and efficiency of your entire fluid system.

Summary Table:

| Benefit | Description |

|---|---|

| Pulsation Dampening | Absorbs pressure spikes and smooths flow from positive displacement pumps. |

| Chemical Resistance | Inert to most acids, bases, and solvents, ensuring process purity and longevity. |

| Leak-Proof Seal | Provides a seamless, flexible barrier to prevent leaks of hazardous fluids. |

| Durability & Uptime | Withstands constant flexing for long service life and reduced maintenance downtime. |

| Equipment Protection | Shields valves, gauges, and pipes from damaging vibration and fatigue. |

Protect your fluid systems with precision-engineered PTFE components from KINTEK.

Whether your priority is handling aggressive chemicals in semiconductor production, ensuring purity in pharmaceutical or laboratory applications, or maximizing uptime in industrial processes, KINTEK has the solution. We specialize in custom fabricating high-performance PTFE seals, liners, bellows, and labware—from initial prototypes to high-volume production—to meet your exact specifications.

Contact our experts today to discuss how our PTFE components can enhance the reliability, safety, and efficiency of your pulse dampeners and other critical equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications