To be clear, the seat material (NBR vs. PTFE) and the valve body style (wafer vs. lug) are two independent design choices that address different operational challenges. NBR is a flexible, cost-effective rubber ideal for moderate conditions like oil and water, while PTFE is a rigid polymer offering superior resistance to aggressive chemicals and extreme temperatures. The valve style—wafer or lug—is chosen based on mechanical installation and maintenance requirements, not the seat material itself.

Your selection process should treat these as two separate decisions. First, choose the seat material (NBR or PTFE) based on the chemical and thermal demands of your media. Second, choose the body style (wafer or lug) based on the physical installation and serviceability needs of your piping system.

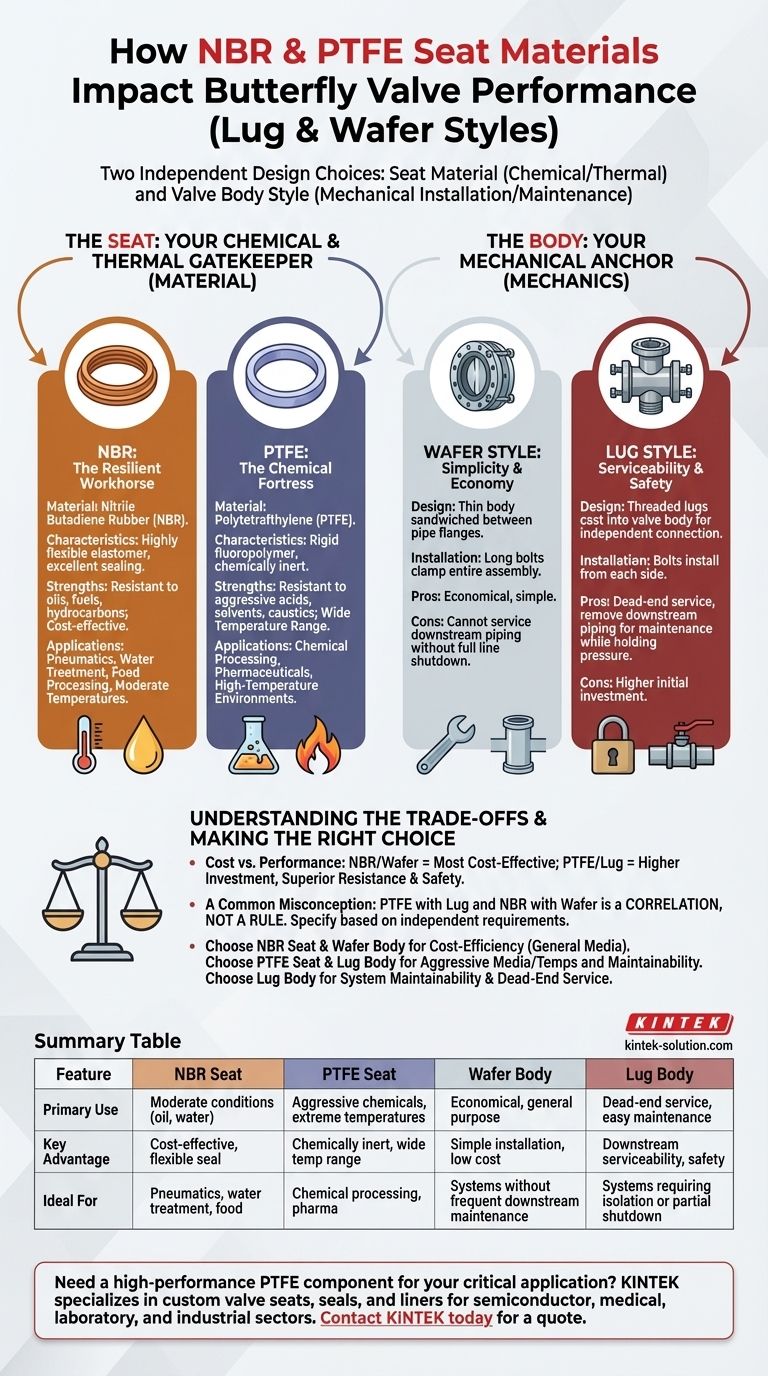

The Two Key Decisions: Material vs. Mechanics

A butterfly valve's performance is not a single characteristic. It's a combination of its chemical resilience and its mechanical integrity. Confusing these two aspects is a common and costly mistake.

The Seat: Your Chemical and Thermal Gatekeeper

The valve seat creates the seal against the disc. Its material is the component in direct, constant contact with the process media.

This means the seat material's properties—not the valve's metal body—dictate its suitability for a specific fluid or temperature range.

The Body: Your Mechanical Anchor

The valve body style determines how the valve is installed and serviced. This is a purely mechanical consideration related to safety, maintenance, and system design.

A lug-style body offers greater security and serviceability but has no inherent impact on the valve's ability to handle corrosive chemicals compared to a wafer style.

NBR vs. PTFE: A Tale of Two Materials

Choosing between these two materials is the most critical factor for ensuring long-term reliability and safety.

NBR: The Resilient Workhorse

NBR (Nitrile Butadiene Rubber) is a highly flexible elastomer known for its excellent sealing capabilities in general-purpose applications.

Its primary strengths are its resistance to oils, fuels, and hydrocarbon-based fluids. It is also very cost-effective. NBR is the default choice for pneumatic systems, water treatment, and food processing applications operating under moderate temperatures.

PTFE: The Chemical Fortress

PTFE (Polytetrafluoroethylene) is a fluoropolymer prized for its near-universal chemical inertness and wide operating temperature range.

It can handle highly aggressive acids, solvents, and caustics that would destroy NBR almost instantly. PTFE is the clear choice for harsh chemical processing, pharmaceuticals, and high-temperature applications.

Wafer vs. Lug: The Mechanical Decision

This choice is about how the valve connects to your piping and what happens when you need to perform maintenance.

The Wafer Style: Simplicity and Economy

A wafer-style butterfly valve is the most common and economical design. It is a thin body that is sandwiched between two pipe flanges.

Long bolts pass through both flanges and the valve body itself, clamping the entire assembly together. Its main drawback is that you cannot service the downstream piping without shutting down the entire line.

The Lug Style: Serviceability and Safety

A lug-style butterfly valve has threaded "lugs" or inserts cast into the valve body. This allows bolts to be installed from each side, connecting the valve to each pipe flange independently.

This design allows the valve to be used for dead-end service and enables the removal of downstream piping for maintenance while the valve remains in place, holding back pressure.

Understanding the Trade-offs

Making the right choice requires balancing performance, safety, and budget.

Cost vs. Performance

There is a significant cost difference between these options. An NBR seat in a wafer-style body is one of the most cost-effective valve configurations available.

Conversely, a PTFE seat in a lug-style body represents a much higher initial investment, justified by its superior chemical resistance and enhanced safety and serviceability features.

A Common Misconception

It's common to see PTFE seats in lug-style valves and NBR seats in wafer-style valves. This is a correlation, not a rule.

Applications requiring expensive PTFE for chemical resistance often also warrant the added safety and serviceability of a lug-style body. However, you can specify the material and body style you need independently based on your specific requirements.

Making the Right Choice for Your Application

Break down your decision based on your primary operational driver.

- If your primary focus is cost-efficiency for general media: Choose an NBR seat. A wafer-style body is likely sufficient and will be the most economical choice.

- If your primary focus is handling aggressive chemicals or extreme temperatures: You must use a PTFE seat. Select a lug-style body if downstream serviceability or dead-end service is a requirement.

- If your primary focus is system maintainability: A lug-style body is the only choice, as it allows for the isolation of downstream equipment without a full system shutdown.

Ultimately, a reliable system is built by selecting each component for its specific purpose.

Summary Table:

| Feature | NBR Seat | PTFE Seat | Wafer Body | Lug Body |

|---|---|---|---|---|

| Primary Use | Moderate conditions (oil, water) | Aggressive chemicals, extreme temperatures | Economical, general purpose | Dead-end service, easy maintenance |

| Key Advantage | Cost-effective, flexible seal | Chemically inert, wide temp range | Simple installation, low cost | Downstream serviceability, safety |

| Ideal For | Pneumatics, water treatment, food processing | Chemical processing, pharmaceuticals | Systems without frequent downstream maintenance | Systems requiring isolation or partial shutdown |

Need a high-performance PTFE component for your critical application?

KINTEK specializes in manufacturing precision PTFE components—including custom valve seats, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring chemical resistance, durability, and reliability for your most demanding environments.

Contact KINTEK today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials