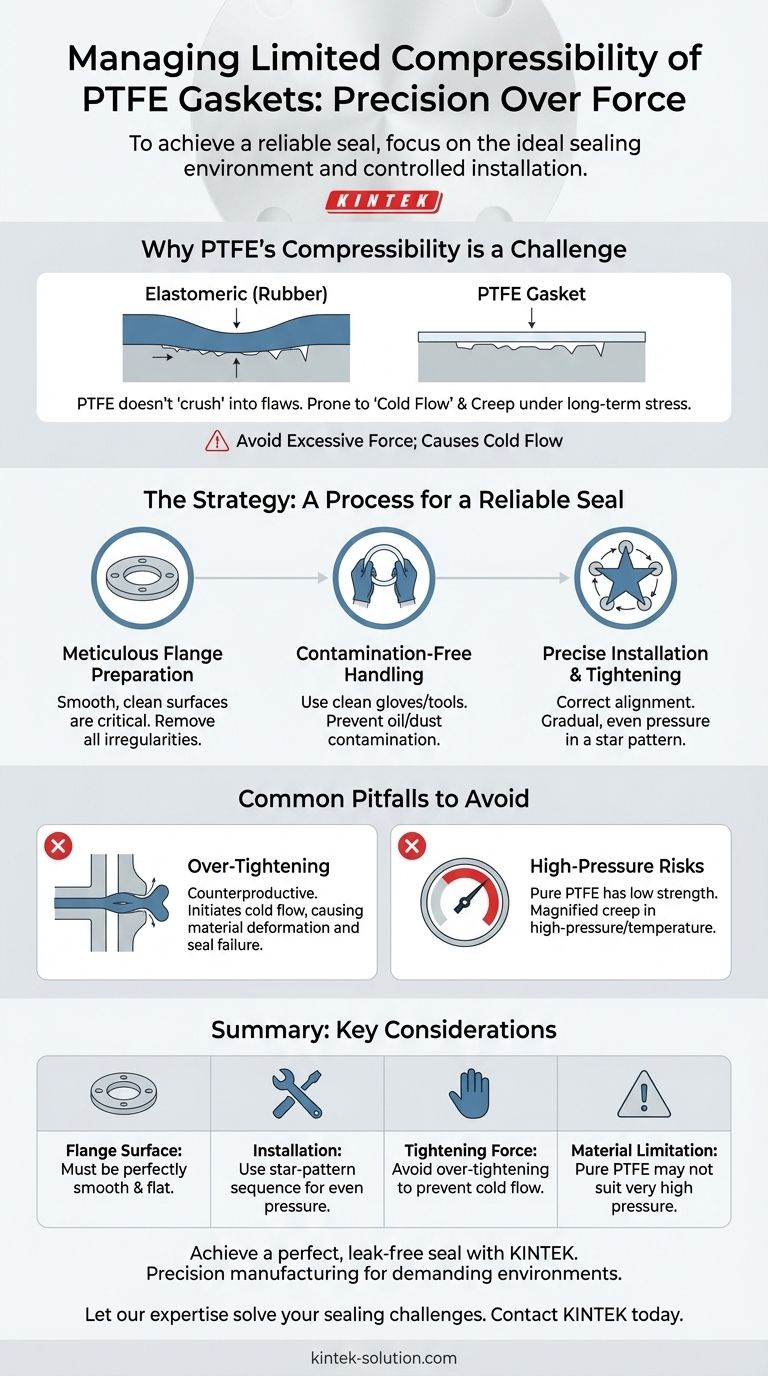

To manage the limited compressibility of PTFE gaskets, you must focus on creating an ideal sealing environment through meticulous flange surface preparation and a highly controlled installation process. Because PTFE does not easily conform to imperfections, you cannot rely on compressive force to create a seal; you must eliminate the imperfections themselves.

The core challenge with PTFE is that it doesn't "crush" into surface flaws like a rubber gasket. Instead of applying more force, which can cause detrimental "cold flow," the solution is to perfect the mating surfaces and apply seating stress with absolute precision.

Why PTFE's Compressibility is a Challenge

Unlike elastomeric materials that compress and rebound to fill gaps, Polytetrafluoroethylene (PTFE) behaves differently under pressure. Understanding its unique mechanical properties is the first step to achieving a reliable seal.

The Problem of "Cold Flow" and Creep

PTFE is a relatively soft material prone to creep, which is a gradual deformation under long-term stress. It also exhibits cold flow, a tendency to deform and "flow" away from pressure, even at lower stress levels and elevated temperatures. This means the gasket material can slowly move out of the sealed area, leading to a loss of sealing integrity over time.

The Impact on Imperfect Surfaces

The limited compressibility means a PTFE gasket has difficulty conforming to flange surfaces that are not perfectly smooth and flat. Scratches, pits, or other irregularities create leak paths that the gasket material cannot easily fill. Applying excessive pressure to try and force it into these gaps will only accelerate cold flow and worsen the problem.

The Strategy: A Process for a Reliable Seal

Because the material itself is not forgiving, your process must be. Success depends on careful execution at every stage, from preparation to final tightening.

Step 1: Meticulous Flange Preparation

This is the most critical step. The goal is to make the flange surfaces as clean, smooth, and uniform as possible. Any existing irregularities must be addressed before the gasket is installed. The gasket cannot compensate for a flawed surface.

Step 2: Contamination-Free Handling

Always handle PTFE gaskets with clean gloves or tools. Contamination from oils, dust, or other particles on your hands can compromise the seal. Similarly, avoid using sharp tools that could scratch the gasket's surface, as even minor damage can create a potential failure point.

Step 3: Precise Installation and Tightening

Proper installation ensures that pressure is distributed evenly across the gasket surface. First, ensure the gasket is the correct size and is perfectly aligned with the flange faces. Then, tighten the bolts gradually in a diagonal or star pattern to apply even pressure. This controlled approach seats the gasket correctly without concentrating stress in one area.

Common Pitfalls to Avoid

Understanding the limitations of PTFE is just as important as knowing the proper procedures. Certain common mistakes can guarantee a seal failure.

The Risk of Over-Tightening

The natural instinct when facing a potential leak is to apply more torque. With PTFE, this is counterproductive. Over-tightening will not improve the seal; it will initiate cold flow, causing the gasket material to deform and extrude from the flange, leading to a complete loss of bolt load and sealing capability.

Material Weakness in High-Pressure Scenarios

Pure PTFE gaskets have low mechanical strength and poor wear resistance. In high-pressure applications, their tendency to creep and deform is magnified. This can make them unsuitable for certain demanding conditions where maintaining a constant sealing stress is critical.

How to Apply This to Your Project

Your approach should be dictated by your equipment's condition and the operational demands of the application.

- If your primary focus is creating a leak-proof seal with new or well-maintained equipment: Your priority must be a precise, by-the-book installation protocol, with special attention to even bolt torque.

- If you are dealing with older or imperfect flange surfaces: You must invest the time to resurface and clean the flanges properly; the gasket cannot and will not compensate for these flaws.

- If you are working in high-pressure or high-temperature systems: Acknowledge that pure PTFE's tendency for cold flow may be a limiting factor and a reinforced or alternative gasket material might be necessary.

Ultimately, achieving a dependable seal with PTFE is a matter of precision and control, not brute force.

Summary Table:

| Key Consideration | Action Required |

|---|---|

| Flange Surface | Must be perfectly smooth and flat; imperfections cause leaks. |

| Installation | Use a star-pattern bolt tightening sequence for even pressure. |

| Tightening Force | Avoid over-tightening to prevent cold flow and seal failure. |

| Material Limitation | Pure PTFE may be unsuitable for very high-pressure applications. |

Achieve a perfect, leak-free seal with PTFE components from KINTEK.

Managing PTFE's unique properties requires precision manufacturing and expert application knowledge. KINTEK specializes in high-performance, custom-fabricated PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our commitment to precision production ensures your gaskets perform reliably in demanding environments.

Let our expertise solve your sealing challenges. Contact KINTEK today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability