In short, PTFE lip seals are used in demanding industrial applications where standard elastomer seals would quickly fail. They are a high-performance solution for sealing high-speed rotating shafts in equipment like air compressors, chemical pumps, mixers, and gearboxes that operate under extreme temperatures, high pressures, or exposure to aggressive chemicals.

The core reason for using a PTFE lip seal is to solve a sealing problem that is beyond the capability of a conventional rubber seal. They are not a simple replacement but a specialized component engineered for longevity and reliability in the most challenging operational environments.

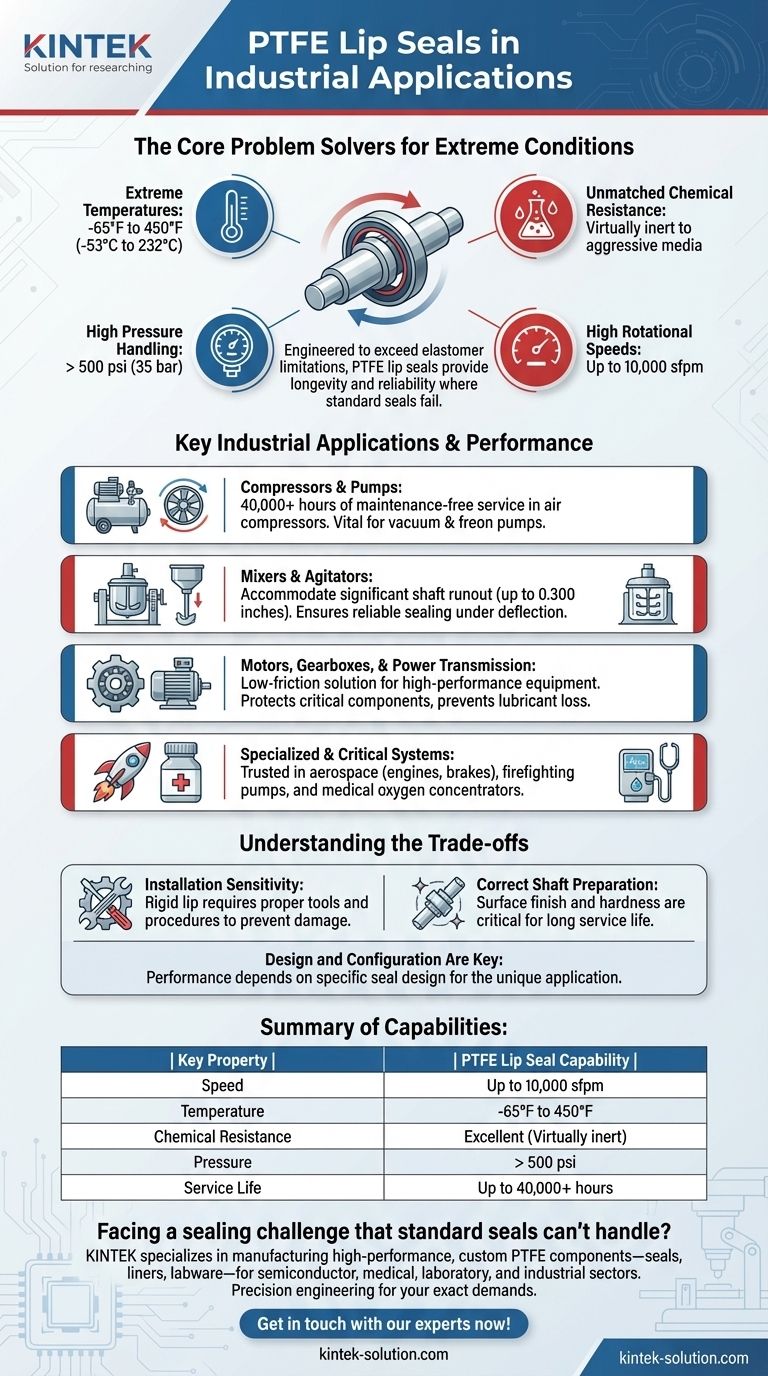

The Core Problem PTFE Lip Seals Solve

PTFE lip seals are fundamentally problem-solvers. They are specified when the operational conditions of a rotating shaft—speed, temperature, pressure, or chemical environment—are too severe for traditional sealing materials.

Exceeding Elastomer Limitations

Standard elastomer (rubber) seals have a limited operational window. PTFE seals are chosen when applications exceed these limits, offering a significantly more robust and durable alternative.

Handling High Rotational Speeds

The inherently low friction of PTFE allows these seals to operate at very high surface speeds, often up to 10,000 surface feet per minute (sfpm). This is critical in equipment like rotary screw compressors (1,000-6,000 RPM) and turbochargers (up to 36,000 RPM), where a rubber seal would generate excessive heat and wear out rapidly.

Tolerating Extreme Temperatures

PTFE maintains its integrity across a vast temperature range, typically from -65°F to 450°F (-53°C to 232°C). This makes it the ideal choice for cryogenic applications as well as high-heat environments like aircraft engines and industrial blowers.

Providing Unmatched Chemical Resistance

PTFE is virtually inert to most industrial chemicals, acids, and solvents. This makes it essential for use in chemical pumps, mixers, and processing equipment where aggressive media would degrade other materials. FDA-compliant grades are also available for food, beverage, and pharmaceutical applications.

Withstanding High Pressure

While primarily designed for dynamic sealing, PTFE lip seals can be engineered to handle significant pressures, often in excess of 500 psi (35 bar). This capability is valuable in hydraulic actuators and certain compressor systems.

A Survey of Key Industrial Applications

The unique properties of PTFE seals make them indispensable across a wide range of critical industries and machinery.

Compressors and Pumps

This is a primary application area. In industrial air compressors, PTFE seals can deliver over 40,000 hours of maintenance-free service. They are also vital in vacuum pumps, freon recovery pumps, and blowers where reliability is paramount.

Mixers and Agitators

Industrial mixers often experience significant shaft runout or deflection. PTFE seals can be designed to accommodate shaft deflection up to 0.300 inches, ensuring a reliable seal where more rigid seal types would fail.

Motors, Gearboxes, and Power Transmission

In high-performance motors, gearboxes, spindles, and robotics, PTFE seals provide a long-lasting, low-friction solution that protects bearings and other critical components from contamination while preventing lubricant loss at high speeds.

Specialized and Critical Systems

The reliability of PTFE seals makes them a trusted component in mission-critical systems. This includes aerospace applications like aircraft engines and brake systems, as well as specialized uses like firefighting pumps handling chemical retardants and piston cup seals in medical oxygen concentrators.

Understanding the Trade-offs

While highly effective, PTFE seals are an engineered solution with specific considerations. They are not a universal drop-in replacement for every elastomer seal.

The Need for Correct Shaft Preparation

To achieve their characteristic long life, PTFE lip seals require a properly prepared shaft. The shaft surface finish and hardness are more critical than with forgiving elastomer seals, as a rough or soft shaft can cause premature wear on the PTFE lip.

Installation Sensitivity

Proper installation is crucial. The relatively rigid nature of a PTFE lip means it can be more susceptible to damage during installation than a flexible rubber seal. Using correct tools and procedures is essential to prevent nicks or scratches that could cause leaks.

Design and Configuration Are Key

The performance of a PTFE seal is heavily dependent on its design, from the profile of the lip to the specific blend of PTFE and filler materials used. Achieving optimal results requires selecting or designing a seal specifically for the application's unique combination of speed, temperature, pressure, and media.

Making the Right Choice for Your Application

Selecting a PTFE seal should be driven by the specific operational challenge you need to overcome.

- If your primary focus is extreme reliability and long service life: PTFE is ideal for equipment like industrial compressors where maintenance is costly and uptime is critical.

- If your primary focus is high-speed rotation: The low-friction nature of PTFE is essential for gearboxes, spindles, and motors to prevent heat buildup and premature wear.

- If your primary focus is chemical or food-grade compatibility: PTFE's chemical inertness makes it the mandatory choice for chemical pumps, mixers, and pharmaceutical equipment.

- If your primary focus is extreme temperature or pressure: PTFE provides the material stability required for aerospace, cryogenic, or high-pressure hydraulic systems where elastomers would fail catastrophically.

Ultimately, PTFE lip seals provide a robust engineering solution that enables machinery to operate reliably under conditions where nothing else will work.

Summary Table:

| Key Property | PTFE Lip Seal Capability |

|---|---|

| Speed | Up to 10,000 sfpm |

| Temperature | -65°F to 450°F (-53°C to 232°C) |

| Chemical Resistance | Excellent (Virtually inert) |

| Pressure | > 500 psi (35 bar) |

| Service Life | Up to 40,000+ hours (e.g., compressors) |

Facing a sealing challenge that standard seals can't handle? KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision engineering and custom fabrication capabilities, from prototypes to high-volume orders, ensure you get a reliable solution tailored to your exact operational demands. Contact us today to discuss how our PTFE lip seals can enhance your equipment's reliability and longevity in extreme conditions. Get in touch with our experts now!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments