Fillers are added to Polytetrafluoroethylene (PTFE) to fundamentally enhance its mechanical and thermal properties, transforming it from a soft, compliant material into a robust engineering plastic. This reinforcement dramatically improves wear resistance, reduces deformation under load, and increases thermal conductivity, making PTFE suitable for a wide range of demanding industrial applications where virgin PTFE would fail.

While pure PTFE is renowned for its chemical inertness and low friction, it suffers from poor wear resistance and "creep" under load. Fillers act as a reinforcing matrix, dramatically improving hardness, wear life, and dimensional stability, though often at the cost of some chemical resistance and electrical insulation.

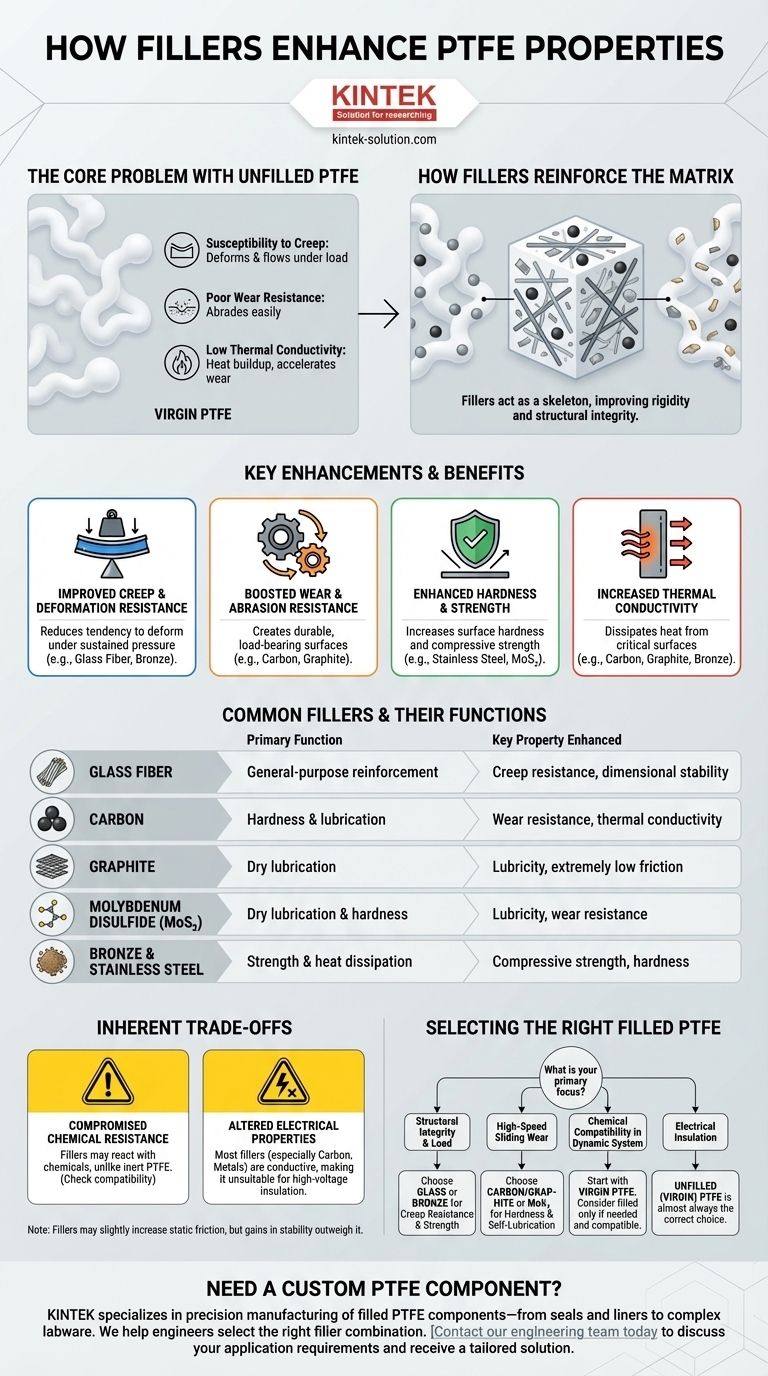

The Core Problem with Unfilled PTFE

To understand the role of fillers, we must first recognize the inherent weaknesses of pure, or "virgin," PTFE. While it has exceptional properties, it has key limitations for mechanical use.

Susceptibility to Creep

Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress. Unfilled PTFE is soft and will slowly change shape or "flow" when a load is applied, especially over time.

Poor Wear Resistance

Despite its low coefficient of friction, virgin PTFE abrades very easily. In dynamic applications like seals or bearings, it wears down quickly, limiting its service life. Research shows filled PTFE can offer up to 1000 times the abrasion resistance.

Low Thermal Conductivity

PTFE is an excellent thermal insulator. In high-speed sliding applications, this is a disadvantage, as frictional heat cannot dissipate effectively. This heat buildup can accelerate wear and cause component failure.

How Fillers Reinforce the PTFE Matrix

Fillers are non-PTFE particles blended into the base resin before it is sintered. These particles create a composite material that physically addresses the weaknesses of the pure polymer.

Improving Creep and Deformation Resistance

Fillers like glass fiber and bronze add rigidity and structural integrity to the PTFE matrix. They act like a skeleton within the material, significantly reducing its tendency to deform under sustained pressure.

Boosting Wear and Abrasion Resistance

Hard particles like carbon and graphite serve as load-bearing points. They create a more durable surface that resists abrasion far better than the soft PTFE resin alone.

Enhancing Hardness and Strength

Metallic fillers like stainless steel or additives like molybdenum disulfide directly increase the surface hardness and compressive strength of the material. This makes it more resistant to indentation and extrusion under high loads.

Increasing Thermal Conductivity

Fillers such as carbon, graphite, and bronze have much higher thermal conductivity than PTFE. They create a pathway for heat to move away from critical surfaces, which is essential for managing friction in high-speed bearings or seals.

Common Fillers and Their Specific Functions

The choice of filler is determined entirely by the demands of the application. Each type imparts a distinct set of properties.

Glass Fiber

This is a general-purpose filler that provides excellent creep resistance and dimensional stability. It is one of the most common and cost-effective ways to improve PTFE's mechanical strength.

Carbon

Carbon enhances hardness, wear resistance, and compressive strength. It also improves thermal conductivity and is electrically conductive, making it unsuitable for applications requiring electrical insulation.

Graphite

Often used in conjunction with carbon, graphite provides excellent self-lubricating properties. This results in an extremely low coefficient of friction, ideal for high-speed, non-lubricated applications.

Molybdenum Disulfide (MoS₂)

Like graphite, MoS₂ is a dry lubricant that enhances lubricity and reduces friction. It also significantly increases the hardness and wear resistance of the PTFE compound.

Bronze & Stainless Steel

These metallic fillers offer the best improvements in strength, hardness, and thermal conductivity. They are ideal for applications requiring high compressive strength and rapid heat dissipation.

Understanding the Inherent Trade-offs

Adding fillers is not a universal upgrade. Enhancing one property often means compromising another, a critical factor in material selection.

Compromised Chemical Resistance

One of PTFE's most prized features is its near-universal chemical inertness. Most fillers do not share this property. The choice of filler must be carefully evaluated against the chemical environment to avoid degradation.

Altered Electrical Properties

Virgin PTFE is an outstanding electrical insulator. Most common fillers, especially carbon and metals, are conductive. This makes most filled PTFE variants unsuitable for high-voltage or high-frequency insulation applications.

A Note on Friction

While fillers drastically improve wear life, some may slightly increase the static coefficient of friction compared to virgin PTFE. However, the gains in dimensional stability and longevity under load almost always outweigh this minor change.

Selecting the Right Filled PTFE for Your Application

The optimal material is the one that directly addresses the primary failure mode of your application.

- If your primary focus is structural integrity under load: Choose glass or bronze-filled PTFE for superior creep resistance and compressive strength.

- If your primary focus is high-speed, sliding wear: Choose a carbon/graphite or molybdenum disulfide-filled PTFE for a combination of hardness and self-lubrication.

- If your primary focus is chemical compatibility in a dynamic system: Start with virgin PTFE and only consider a filled compound if wear or creep is a proven issue, ensuring the filler itself is compatible.

- If your primary focus is electrical insulation: Unfilled (virgin) PTFE is almost always the correct choice.

By understanding these targeted enhancements and their associated trade-offs, you can select a filled PTFE compound precisely engineered to meet your performance requirements.

Summary Table:

| Common Filler | Primary Function | Key Property Enhanced |

|---|---|---|

| Glass Fiber | General-purpose reinforcement | Creep resistance, dimensional stability |

| Carbon/Graphite | Hardness & lubrication | Wear resistance, thermal conductivity |

| Bronze/Stainless Steel | Strength & heat dissipation | Compressive strength, hardness |

| Molybdenum Disulfide | Dry lubrication | Lubricity, wear resistance |

Need a custom PTFE component that balances performance with durability?

KINTEK specializes in precision manufacturing of filled PTFE components—from seals and liners to complex labware. We help engineers in the semiconductor, medical, laboratory, and industrial sectors select the right filler combination (glass, carbon, bronze, and more) to combat creep, improve wear life, and enhance thermal management.

Whether you require prototypes or high-volume production, our expertise ensures your PTFE parts meet exacting specifications. Contact our engineering team today to discuss your application requirements and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials