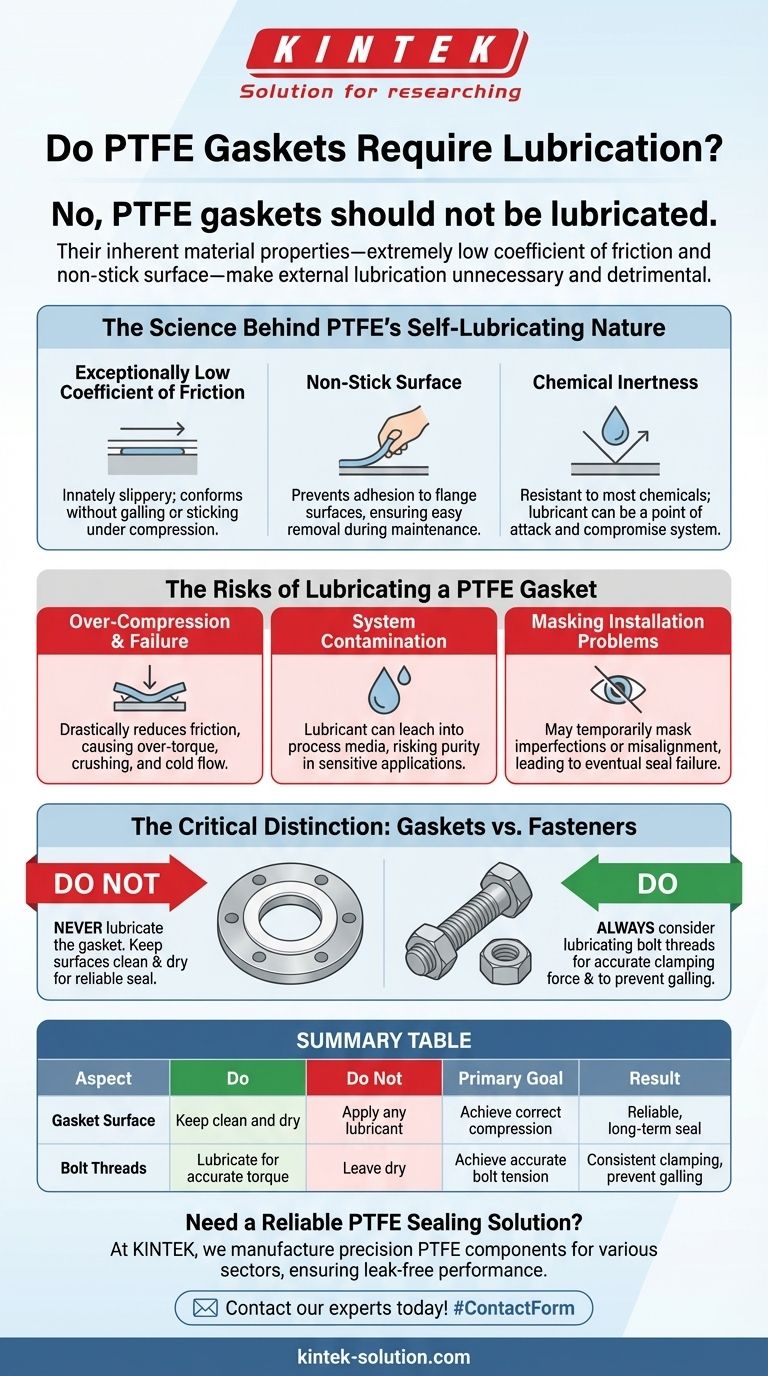

No, PTFE gaskets should not be lubricated. Their inherent material properties, specifically an extremely low coefficient of friction and a non-stick surface, make any external lubricant unnecessary for achieving a proper seal. Adding a lubricant to the gasket surface can actually be detrimental to the integrity of the connection.

The core principle of sealing with PTFE is to rely on its natural slipperiness for proper seating. Applying lubricant to the gasket itself introduces a significant risk of over-compression and failure, while proper lubrication of the bolt threads is the correct practice for achieving accurate clamping force.

The Science Behind PTFE's Self-Lubricating Nature

Understanding why PTFE (polytetrafluoroethylene) behaves this way is crucial for proper installation. The material's unique molecular structure gives it properties that are ideal for sealing without any external aids.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This innate "slipperiness" allows the gasket to easily conform and seat into the flange surfaces under compression without galling or sticking.

Non-Stick Surface

The same properties that make PTFE non-stick in cookware prevent it from adhering to flange surfaces. This ensures that the gasket can be easily removed during maintenance without damaging the flanges, a task for which lubricants are sometimes used with other gasket materials.

Chemical Inertness

PTFE is virtually inert and resistant to almost all industrial chemicals. Adding a lubricant, which may not share this level of resistance, can introduce a potential point of chemical attack and compromise the entire system.

The Risks of Lubricating a PTFE Gasket

While it may seem like a helpful step, applying substances to a PTFE gasket's sealing surfaces is a common but critical installation error. It actively works against the goal of a reliable, long-term seal.

The Primary Danger: Over-Compression

The most significant risk is over-compressing and destroying the gasket. Fastener torque specifications are calculated based on a certain amount of friction. Lubricating the gasket and flange faces drastically reduces this friction.

When an installer applies the specified torque, the nuts will turn much farther than intended, generating excessive compressive force. This force can easily crush the PTFE material, causing it to cold flow excessively and leading to immediate or eventual seal failure.

Introducing System Contamination

In many applications, such as food processing, pharmaceutical manufacturing, or high-purity chemical lines, maintaining system purity is paramount. Any lubricant applied to the gasket surface can leach into the process media, causing contamination.

Masking Installation Problems

A clean, dry, and properly aligned flange is essential for a good seal. A lubricant might temporarily mask minor surface imperfections or misalignments that should be corrected before assembly, giving a false sense of a proper seal that is destined to fail.

The Critical Distinction: Gaskets vs. Fasteners

The confusion around lubrication often stems from misunderstanding what should be lubricated in a bolted flange connection. The rule is simple: never lubricate the gasket, but always consider lubricating the fasteners.

Lubricate the Bolt Threads

Applying a proper, system-compatible lubricant to the threads of the stud or bolt is a widely accepted best practice.

This practice has nothing to do with the gasket itself. Its purpose is to reduce friction between the nut and the bolt threads, ensuring that the applied torque is translated into consistent, accurate clamping force (bolt stretch).

Prevent Fastener Galling

Lubricating fasteners is especially critical when using stainless steel or other alloys that are prone to galling (thread seizure). This ensures the joint can be properly tightened and, just as importantly, disassembled later for maintenance.

Making the Right Choice for Your Goal

Achieving a reliable, leak-free seal with a PTFE gasket depends on directing your effort to the correct components of the assembly.

- If your primary focus is a reliable, long-term seal: Keep the gasket and flange faces perfectly clean and dry, and achieve the correct compression by applying proper, even torque to the fasteners.

- If your primary focus is preventing system contamination: Never allow any lubricant or foreign substance to touch the gasket's sealing surfaces.

- If your primary focus is achieving accurate bolt tension: Apply an appropriate, high-quality lubricant to the fastener threads and the face of the nuts, well away from the gasket itself.

Ultimately, the key is to trust the material properties of PTFE and focus all installation efforts on clean surfaces and correct fastener tension.

Summary Table:

| Aspect | Do | Do Not |

|---|---|---|

| Gasket Surface | Keep clean and dry | Apply any lubricant |

| Bolt Threads | Lubricate for accurate torque | Leave dry |

| Primary Goal | Achieve correct compression | Mask installation issues |

| Result | Reliable, long-term seal | Risk of over-compression & failure |

Need a Reliable PTFE Sealing Solution?

PTFE's unique properties are key to a successful seal, but proper installation is critical. At KINTEK, we manufacture precision PTFE components—including seals, gaskets, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We ensure your components are made to the highest standards, providing the material reliability you need for leak-free performance.

Let us help you achieve a perfect seal. Contact our experts today to discuss your application or request a custom quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application