Yes, a towel can be used in an absolute emergency, but it is a high-risk substitute for a proper Teflon sheet. While a towel provides a barrier, it lacks the critical non-stick and consistent heat-resistant properties of Teflon, which are essential for protecting both your heat press and your garment from damage.

The core issue isn't just finding a cover, but rather managing heat, preventing adhesion, and ensuring consistency. A Teflon sheet is an engineered tool for this purpose, whereas a towel is a temporary workaround with significant trade-offs.

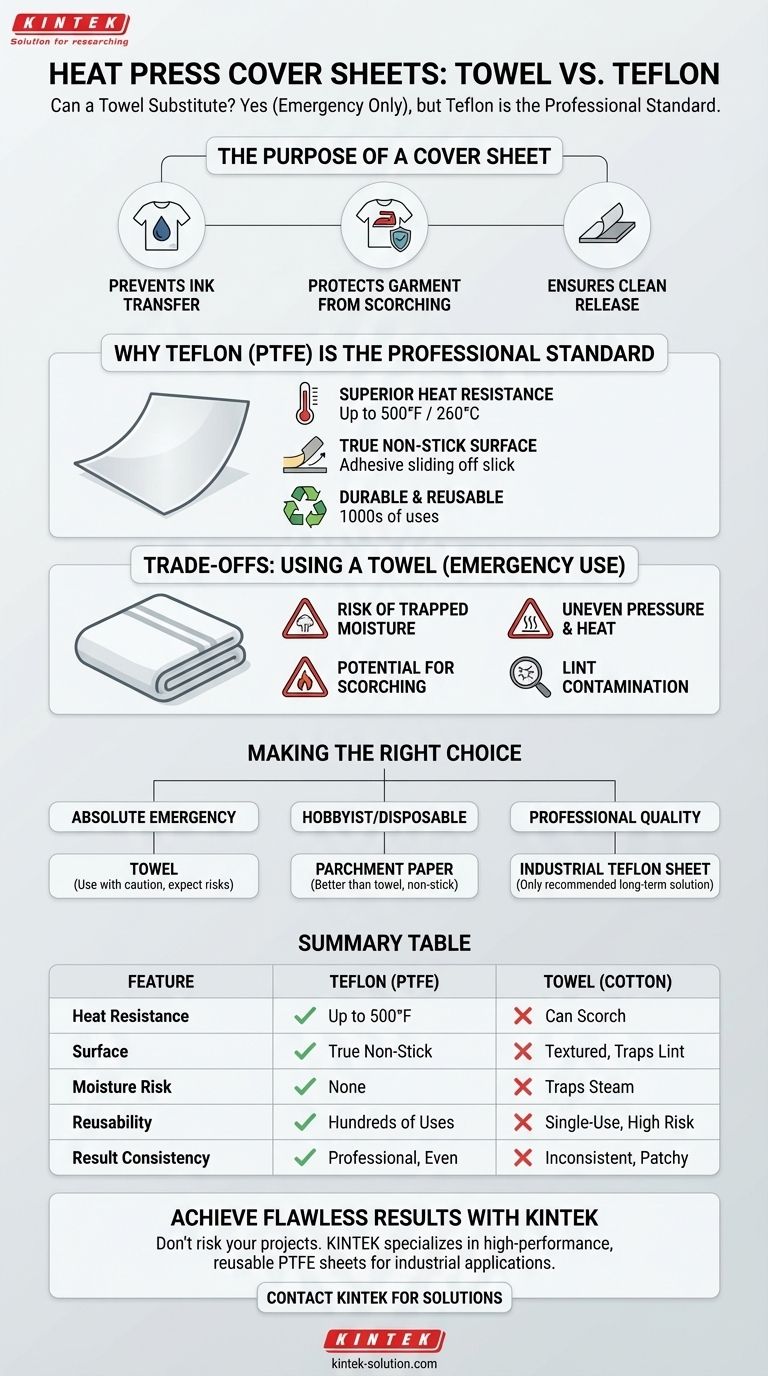

The Purpose of a Protective Cover Sheet

To understand the comparison, we must first establish the non-negotiable roles of a cover sheet in any heat press application.

Preventing Ink and Adhesive Transfer

A primary function is to create a barrier between your design and the heated upper platen of your press. This prevents ink, vinyl, or adhesive from melting onto the platen, which would stain it and transfer to all future projects.

Protecting Your Garment

Direct, high-temperature contact can scorch or even melt certain fabrics. A cover sheet shields the material from direct contact with the metal platen, diffusing the heat slightly and preventing scorch marks.

Ensuring a Clean Release

The cover sheet ensures that when you open the press, nothing sticks to the upper platen. This clean release is critical for a sharp, professional-looking transfer.

Why Teflon is the Professional Standard

A Teflon (PTFE) sheet is specifically designed to excel in the high-heat, high-pressure environment of a heat press.

Superior Heat Resistance

Teflon sheets are rated to withstand temperatures up to 500°F (260°C) or more without degrading. This means they will not burn, scorch, or release fumes within the operating range of any standard heat press.

A True Non-Stick Surface

The defining characteristic of Teflon is its slick, non-stick surface. Inks, adhesives, and vinyl simply do not bond to it, which guarantees a clean release and makes cleanup effortless.

Durability and Reusability

A single Teflon sheet can be wiped clean and reused for thousands of pressings. This makes it a cost-effective and reliable tool for anyone serious about producing quality results.

Understanding the Trade-offs: Using a Towel

Using a common household towel introduces several variables that can compromise your project and even your equipment.

Risk of Trapped Moisture

Towels can retain ambient moisture from the air. When placed under high heat and pressure, this moisture turns to steam, which can ruin an adhesive transfer by preventing it from curing properly.

Uneven Pressure and Heat

The texture and weave of a towel create an uneven surface. This can result in inconsistent pressure across your design, leading to patchy transfers where some parts adhere perfectly and others fail.

Potential for Scorching

Most towels are made of cotton, which can begin to scorch at temperatures commonly used for heat pressing. A scorched towel can transfer discoloration to your garment.

Lint Contamination

Towels shed fibers and lint. These tiny particles can get trapped in your design during pressing, creating permanent imperfections in the final product.

Making the Right Choice for Your Goal

Your choice of cover sheet should align directly with your desired outcome and frequency of use.

- If you are in an absolute emergency for a single project: Use a thin, clean, and completely dry tea towel, but be aware of the risks of uneven pressing and potential scorching.

- If you are a hobbyist seeking a disposable alternative: High-quality parchment paper is a far better choice than a towel, as it provides a non-stick surface without the risk of lint or trapped moisture.

- If your primary focus is professional quality and consistency: An industrial Teflon sheet is the only recommended long-term solution for protecting your investment and ensuring flawless results.

Ultimately, protecting your work with the right tool is the simplest step toward achieving a professional finish every time.

Summary Table:

| Feature | Teflon (PTFE) Sheet | Towel (Cotton) |

|---|---|---|

| Heat Resistance | Up to 500°F (260°C) | Can scorch at heat press temperatures |

| Surface | True non-stick | Textured, can trap lint |

| Moisture Risk | None | Can trap steam, ruining transfers |

| Reusability | Hundreds of uses | Single-use, high risk |

| Result Consistency | Professional, even press | Inconsistent, patchy results |

Achieve flawless, professional heat press results every time. Don't risk your projects or equipment with makeshift solutions. KINTEK specializes in manufacturing high-performance, reusable PTFE (Teflon) sheets and components designed for the demanding environments of industrial, laboratory, and specialized applications. Our sheets offer superior non-stick properties, exceptional heat resistance, and unmatched durability.

Whether you need a standard size or a custom-fabricated solution for your unique press, we provide precision production from prototypes to high-volume orders.

Contact KINTEK today to protect your investment and ensure consistent, high-quality transfers.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems