Yes, absolutely. PTFE (Polytetrafluoroethylene) flange gaskets are not only customizable, but their capacity for customization is a primary reason for their widespread use in demanding industrial applications. You can tailor them by size, shape, and even material composition to achieve a precise fit and optimal performance for your specific operational requirements.

Customization is a core feature of PTFE gasket technology. It moves beyond simply matching a flange size to engineering a specific sealing solution designed to withstand the unique chemical, thermal, and mechanical stresses of your application.

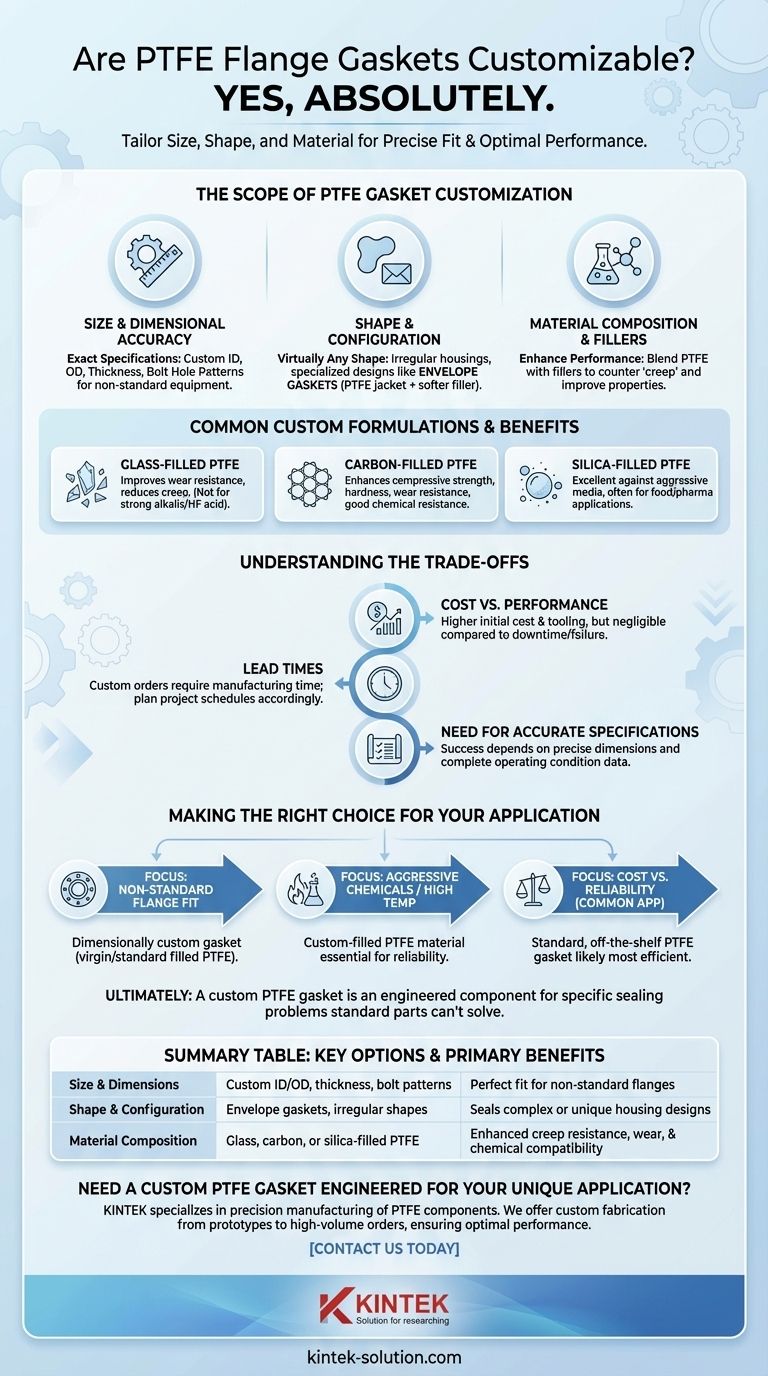

The Scope of PTFE Gasket Customization

True customization goes far beyond just ordering a non-standard diameter. It involves tailoring multiple aspects of the gasket to create a component that is perfectly suited for its intended environment.

Size and Dimensional Accuracy

The most basic level of customization is dimensional. Manufacturers can fabricate gaskets to your exact specifications, ensuring a perfect seal for non-standard or legacy equipment. This includes custom inner diameters (ID), outer diameters (OD), thickness, and specific bolt hole patterns.

Shape and Configuration

PTFE gaskets are not limited to simple flat rings. Using advanced machining techniques, they can be produced in virtually any shape to fit irregularly shaped housings or complex sealing faces. This includes specialized designs like envelope gaskets, where a PTFE "jacket" encloses a softer filler material to combine chemical resistance with improved compressibility.

Material Composition and Fillers

This is the most critical area of customization for performance. Virgin PTFE is known for its incredible chemical inertness but can be prone to "creep" or cold flow under pressure. To counteract this and enhance other properties, PTFE can be blended with various fillers.

Common custom formulations include:

- Glass-Filled PTFE: Improves wear resistance and reduces creep, but is not suitable for strong alkalis or hydrofluoric acid.

- Carbon-Filled PTFE: Enhances compressive strength, hardness, and wear resistance while providing good chemical resistance.

- Silica-Filled PTFE: Often used in food and pharmaceutical applications, it offers excellent performance against a wide range of aggressive media.

Understanding the Trade-offs

While customization offers significant advantages, it is important to approach it with a clear understanding of the associated considerations.

Cost vs. Performance

Custom-fabricated gaskets will inherently have a higher unit cost and may require tooling charges compared to standard, off-the-shelf parts. However, this initial investment is often negligible compared to the cost of downtime, product loss, or safety incidents caused by a failed standard gasket.

Lead Times

Standard gaskets are typically in stock and ready to ship. Custom gaskets are made to order, which introduces a manufacturing lead time. This must be factored into your project planning and maintenance schedules to avoid delays.

The Need for Accurate Specifications

The success of a custom gasket depends entirely on the quality of the information you provide. Inaccurate dimensions or an incomplete understanding of the operating conditions (pressure, temperature, and chemical media) will result in a gasket that fails to perform as expected.

Making the Right Choice for Your Application

Use your specific goal to determine the level of customization you need.

- If your primary focus is fitting a non-standard flange: A dimensionally custom gasket made from virgin or standard filled PTFE is your solution.

- If your primary focus is sealing aggressive chemicals or operating at high temperatures: A custom-filled PTFE material is essential for long-term reliability and safety.

- If your primary focus is balancing cost with reliability for a common application: A standard, off-the-shelf PTFE gasket is likely the most efficient and economical choice.

Ultimately, a custom PTFE gasket is an engineered component designed to solve a specific sealing problem that standard parts cannot.

Summary Table:

| Customization Aspect | Key Options | Primary Benefit |

|---|---|---|

| Size & Dimensions | Custom ID/OD, thickness, bolt patterns | Perfect fit for non-standard flanges |

| Shape & Configuration | Envelope gaskets, irregular shapes | Seals complex or unique housing designs |

| Material Composition | Glass, carbon, or silica-filled PTFE | Enhanced creep resistance, wear, and chemical compatibility |

Need a custom PTFE gasket engineered for your unique application? KINTEK specializes in precision manufacturing of PTFE components, including seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your gaskets deliver optimal performance under specific chemical, thermal, and mechanical stresses. Contact us today to discuss your requirements and get a tailored solution that maximizes reliability and safety!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability