You’ve done everything by the book. The sample was prepared perfectly. The multi-million dollar LC/GC system is calibrated. Your method is validated. Yet, the chromatogram on your screen tells a story of failure.

A peak that should be sharp and consistent is worryingly variable. A critical analyte appears to have a lower concentration than expected. You run the analysis again. Same frustrating, unreliable result. Suddenly, a full day’s work—or even a week's—is in question, and you have no clear explanation why.

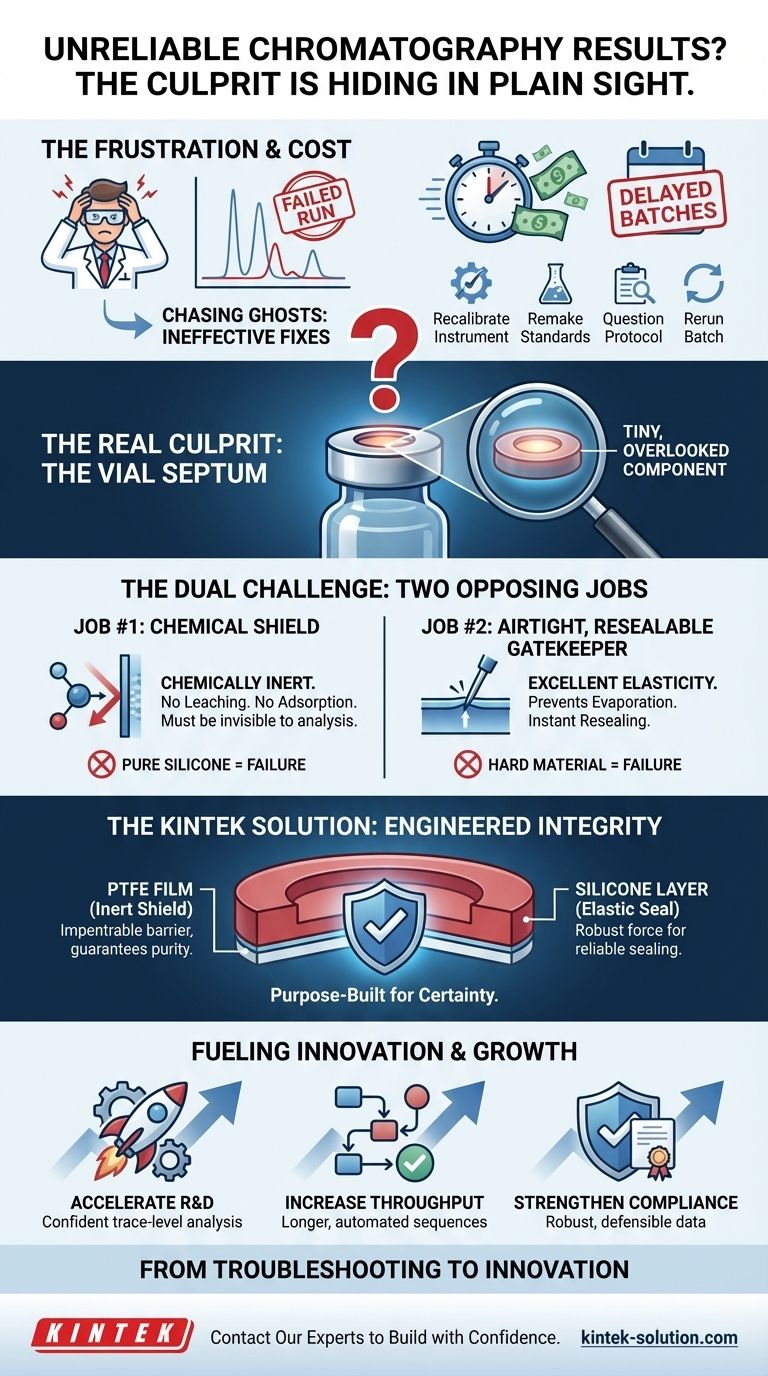

Chasing Ghosts: Why the Usual Fixes Don’t Work

For any lab manager or research scientist, this scenario is both familiar and costly. The immediate reaction is to troubleshoot the most complex and expensive parts of the process.

You might spend hours:

- Recalibrating the instrument’s detector or injector.

- Remaking all your standards and controls from scratch.

- Questioning the sample preparation protocol or the technician’s execution.

- Rerunning the entire batch, hoping for a different outcome.

This cycle of troubleshooting isn't just an academic frustration; it's a significant business bottleneck. Each failed run leads to delayed batch releases for life-saving drugs, wasted high-value reagents, and mounting pressure from project managers. When you can't trust your data, you can't confidently release a product, publish research, or pass a regulatory audit. The financial and reputational costs are immense.

But what if the problem isn’t your process, your people, or your expensive equipment? What if the saboteur is a tiny, overlooked component costing less than a dollar?

The Real Culprit: A Tale of Two Materials

The root cause of this chaos is often hiding in the one place most people never think to look: the vial septum. This small disc of material is the only thing standing between your pristine sample and the outside world. To do its job correctly, it must perform two completely different, non-negotiable tasks simultaneously.

This is the core conflict that many "solutions" fail to address. They treat the septum as a simple plug, but it’s a sophisticated gatekeeper.

Job #1: The Chemically Inert Shield

The part of the septum that touches your sample must be completely invisible to your analysis. It cannot add anything to your sample (leaching) or steal anything from it (adsorption). Pharmaceutical solvents can be highly aggressive, and if your septum material reacts even slightly, it will contaminate the sample and corrupt your data. This is why a simple rubber or pure silicone plug often fails spectacularly; it’s not chemically inert enough for sensitive applications.

Job #2: The Airtight, Resealable Gatekeeper

The septum must also create a perfect, gas-tight mechanical seal against the vial rim to prevent evaporation—which would falsely increase your sample’s concentration. Furthermore, when the autosampler needle punctures it, it must reseal itself instantly to maintain that protection. This requires a material with excellent elasticity and compressibility—a property that hard, chemically-resistant materials often lack.

The common, low-cost "solutions" fail because they only solve for one of these jobs. A pure silicone septum provides a great seal (Job #2) but can fail catastrophically at being chemically inert (Job #1). This is the hidden reason for your inconsistent results: your septum is silently altering your sample before it ever reaches the detector.

Engineered for Integrity: The Purpose-Built Solution

To solve this, you don't need a better instrument; you need a better barrier. You need a component engineered from the ground up with this dual-functionality in mind.

This is precisely why PTFE/Silicone septa were developed. It's not a happy accident; it's a piece of precision engineering designed specifically to conquer this dual challenge.

- A thin, non-reactive PTFE film faces the sample. As one of the most chemically inert polymers known, it acts as an impenetrable shield, guaranteeing that nothing leaches into or adsorbs out of your sample. It flawlessly performs Job #1.

- A thicker, high-purity silicone layer sits behind it. Its elasticity provides the robust, compressible force needed for an airtight seal and reliable resealing after puncture. It perfectly handles Job #2.

A KINTEK PTFE/Silicone septum is the physical embodiment of this solution. We don't just sell components; we manufacture certainty. Our precision production processes ensure that the PTFE layer is uniform and flawless, and that the silicone provides a consistent, reliable seal every single time. By understanding the fundamental science of sample integrity, we build the components that make reliable data possible.

From Fighting Fires to Fueling Innovation

When you eliminate the vial septum as a random source of error, you’re not just fixing a problem—you’re unlocking new potential. The time and resources once spent chasing phantom issues can be reinvested into what truly matters.

- Accelerate R&D: Your research teams can confidently tackle more sensitive trace-level analyses and complex drug formulations without second-guessing their baseline data.

- Increase Throughput: Your QA/QC department can run longer, automated sequences with the assurance that sample integrity will be maintained from the first injection to the last.

- Strengthen Compliance: You can face regulatory audits with robust, defensible data, knowing that your entire analytical workflow is built on a foundation of reliability.

Ultimately, by solving this one small but critical issue, you move your entire operation from a reactive state of troubleshooting to a proactive state of innovation and growth.

Solving the septum problem is just one example of how a deep understanding of material science can eliminate critical business risks. Your challenges may be different—from outgassing in a semiconductor process to chemical compatibility in a medical device. But the principle is the same: the right material, precision-engineered for the task, is the foundation of success. Our experts are ready to apply their deep knowledge of PTFE fabrication to your specific project, ensuring reliability from prototype to production. Contact Our Experts to discuss how we can help you build with confidence.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

Related Articles

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault