You've done everything by the book. The flange surfaces were clean, the new PTFE gasket was carefully installed, and the bolts were tightened to spec. Yet a week later, there it is: a tell-tale wisp of vapor, a dreaded drip on the floor, or a pressure gauge that simply won't hold steady. Your system has a leak. Again.

So begins a frustrating and costly ritual familiar to many engineers, lab managers, and maintenance teams.

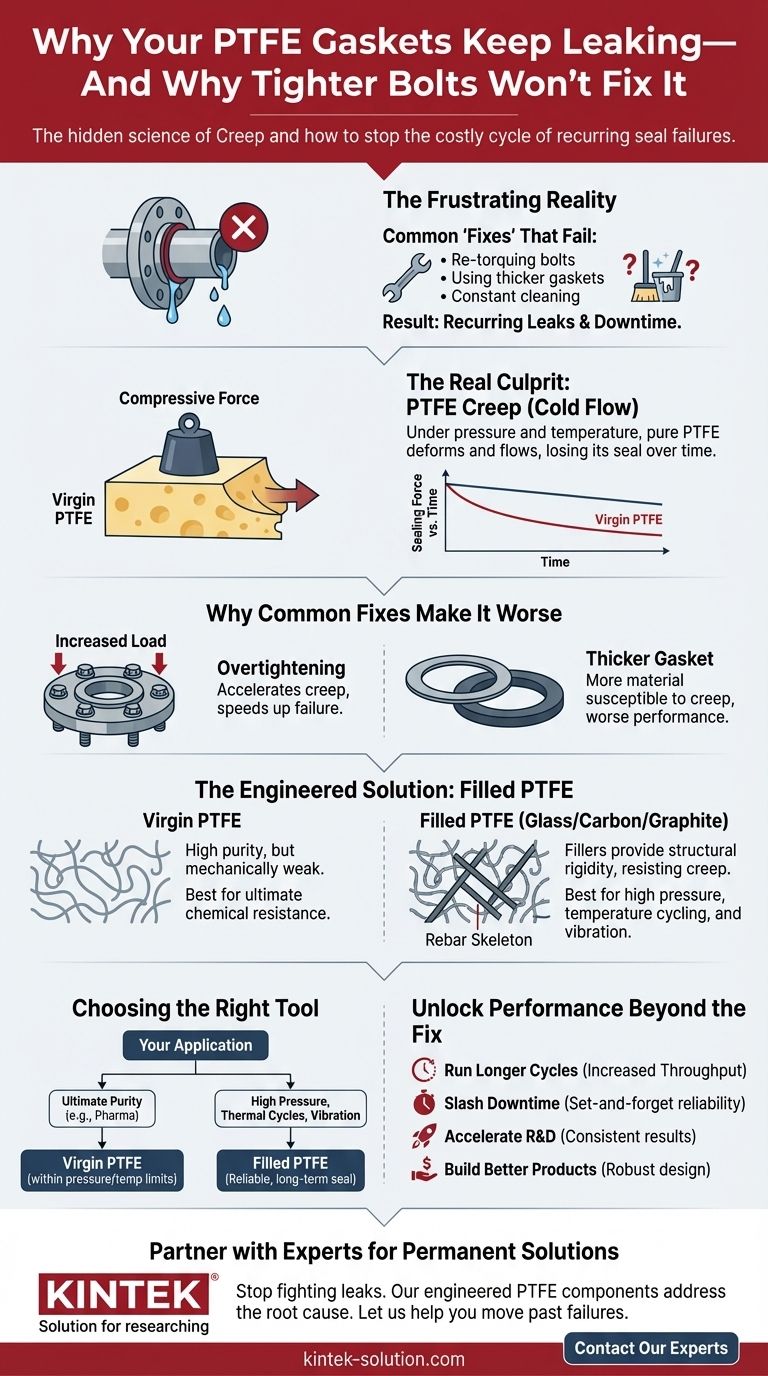

The Costly Cycle of 'Fixes' That Don't Work

When a high-performance PTFE gasket fails, the immediate assumption is an error in installation or selection. You and your team are sent chasing ghosts:

- "Maybe the bolts weren't tight enough?" You re-torque everything, sometimes exceeding specifications, hoping more force will solve the problem.

- "Maybe the gasket was too thin?" You order a thicker 1/8" gasket to replace the 1/16" one, assuming more material will fill any potential gaps.

- "Maybe the surface was contaminated?" You shut down the line, disassemble the entire flange joint, meticulously clean every surface, and reinstall a brand-new gasket.

Each attempt costs hours, if not days, of expensive downtime. For a semiconductor fab, it can mean a contaminated batch worth thousands. In a chemical plant, it represents a safety hazard and lost production. For a medical device, it's a potential point of failure that is simply unacceptable.

And yet, the leak often returns. Why? Because these common "fixes" are merely treating a symptom, not the underlying disease.

The Real Culprit: Meet 'Creep,' Your System's Silent Saboteur

The reason your PTFE gaskets are failing has less to do with your installation process and more to do with the fundamental physics of the material itself. The culprit is a phenomenon called creep, or cold flow.

Imagine a block of hard cheese sitting on a counter with a heavy weight on top of it. Even at room temperature, the cheese will slowly flatten and spread out over time.

This is exactly what happens to a standard PTFE gasket.

Under the constant compressive force from the bolted flanges, the "pure" or "virgin" PTFE material slowly flows outwards, away from the pressure. As it deforms, it loses its initial compressive force. The tight, leak-proof seal you created during installation literally loosens itself over hours or days. Vibration and temperature cycles dramatically accelerate this process.

Now, it becomes clear why the common "fixes" fail:

- Overtightening bolts only increases the compressive load, which actually accelerates creep and causes the gasket to fail faster.

- Using a thicker gasket provides more material that is susceptible to creep, often making the problem worse, not better.

You're not failing at installation. You're fighting a battle against the inherent nature of the material you're using.

Fighting Creep with Smarter Material, Not More Force

To achieve a permanent, reliable seal, you don't need more bolt torque. You need a material that is engineered from the ground up to resist creep.

This is where the distinction between "virgin PTFE" and "filled PTFE" becomes the most important decision you can make. While virgin PTFE offers the absolute highest chemical purity, its mechanical weakness makes it unsuitable for many demanding pressure or thermal cycling applications.

Filled PTFE is the engineered solution to this problem.

By incorporating specific additives—like glass fiber, carbon, or graphite—into the base PTFE, the material's properties are fundamentally changed. These fillers act like a microscopic rebar skeleton within the PTFE matrix. They provide structural rigidity and support, drastically reducing the material's tendency to creep or flow under pressure.

Virgin vs. Filled PTFE: Choosing the Right Tool for the Job

A professional doesn't use a single wrench for every bolt, and you shouldn't use a single type of PTFE for every application. The solution lies in selecting the material that directly counters the primary stress in your system.

- For ultimate purity (e.g., pharmaceutical, high-purity semiconductor): Virgin PTFE is the correct choice, but the system must be designed to operate within its lower pressure and temperature limits.

- For high pressure, temperature cycles, or vibration: A filled PTFE is essential. The filler provides the mechanical backbone needed to maintain a continuous, leak-free seal long after virgin PTFE would have failed.

This is not about finding a "better" gasket; it's about a strategic approach to material science. At KINTEK, we don't just supply PTFE components. We manufacture them based on a deep understanding of these failure modes. Our ability to fabricate precision parts from both virgin and a wide array of filled PTFE grades isn't just a capability—it's the embodiment of the solution to the problem of creep. We provide the right tool for the job.

Beyond the Fix: From Preventing Leaks to Unlocking Performance

When you stop fighting recurring gasket failures, something powerful happens. The resources once spent on reactive maintenance are freed up, unlocking new potential for your operations.

- Run Longer, More Demanding Cycles: You can now confidently operate your systems at their intended pressures and temperatures without worrying about seal integrity, increasing throughput and efficiency.

- Slash Maintenance Downtime: "Set-and-forget" reliability means your most skilled personnel can focus on value-added projects instead of repeatedly fixing the same flange connection.

- Accelerate R&D: In a lab setting, reliable seals mean your experiments are no longer interrupted by equipment failure, allowing for faster and more accurate data collection.

- Build a More Reliable End Product: For OEMs, designing with the correct, creep-resistant seal from the start means a more robust and dependable product, enhancing your brand's reputation for quality.

Choosing the right gasket is more than just checking a chemical compatibility chart; it's a strategic decision that ensures the long-term reliability, safety, and performance of your entire system. Moving from a generic material to one precisely engineered for your application's mechanical stresses is the difference between a temporary patch and a permanent solution. Your challenge might be a persistent leak, but our expertise addresses the root cause to strengthen your entire operation. Let our team help you move past recurring failures and unlock the full potential of your systems. Contact Our Experts to discuss your unique application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

Related Articles

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- Your "Inert" PTFE Component Might Be the Real Source of System Failure