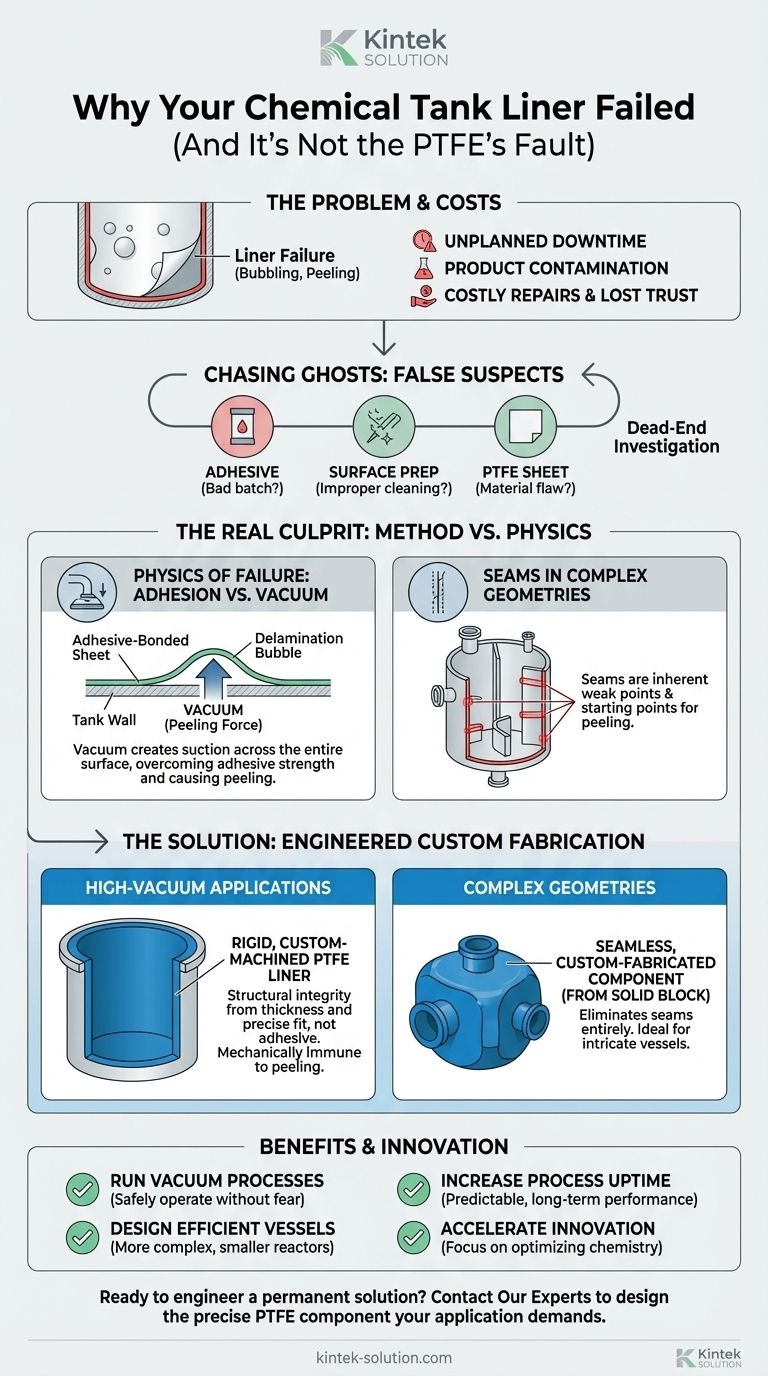

It’s a scenario that keeps plant managers and process engineers up at night. You've invested in a new, large-scale chemical tank, lined with what you were told was the gold standard: PTFE. It was chosen for its legendary chemical resistance, a supposed guarantee of a long, trouble-free service life. Then, weeks or months later, the alarms go off. A post-shutdown inspection reveals the liner has bubbled, peeled away from the wall, and failed. Production is halted, expensive product is potentially contaminated, and a costly, time-consuming repair is now your top priority.

Everyone is asking the same question: "How did the 'best' material fail?"

Chasing Ghosts: Why 'Better' Adhesives and Surfaces Aren't the Answer

This type of failure is frustratingly common, and it often kicks off an investigation that goes in circles. The immediate suspects are usually:

- The Adhesive: Was it a bad batch? Was it applied incorrectly?

- The Surface Prep: Was the metal tank not cleaned or primed properly?

- The PTFE Sheet: Was there a flaw in the material itself?

Teams can spend weeks and significant budget exploring these dead ends. They might specify a "stronger" adhesive or a more rigorous surface preparation protocol for the next installation, only to experience the exact same failure down the line.

The business consequences are severe. Beyond the obvious cost of a new liner and the labor to install it, the unplanned downtime cripples production schedules. For industries like semiconductors or pharmaceuticals, where product purity is paramount, a liner breach can lead to the loss of entire batches, costing hundreds of thousands of dollars. The most significant cost, however, is the erosion of trust in your critical process equipment.

The Hidden Culprit: It's Not the Material, It's the Method

Here is the turning point in understanding this problem: The failure is almost never the fault of the PTFE material itself. The culprit is a fundamental mismatch between the lining method—adhesive-bonded sheets—and the mechanical forces at play within your tank.

The root of the problem lies in a simple fact of physics.

The Physics of Failure: Adhesion vs. Vacuum

PTFE is famous for being non-stick (it has very low surface energy). To get anything to stick to it, the back of a PTFE sheet must be chemically "etched." This process roughens the surface on a molecular level, allowing a specialized, high-strength adhesive to form a bond.

This bond is very strong against shear forces (forces that run parallel to the surface). However, it is fundamentally vulnerable to peeling forces—especially when those forces are applied uniformly over a large area.

And what creates a perfect, uniform peeling force? A vacuum.

If your process involves any level of negative pressure, even small, transient vacuums created during draining or cooling cycles, it creates suction across the entire inner surface of the liner. This suction pulls the sheet directly away from the tank wall. No adhesive, no matter how "strong," can indefinitely resist this peeling force. It will inevitably find a weak point, and a small bubble will form. Once started, delamination spreads rapidly, leading to catastrophic failure.

The same issue applies to tanks with complex internal geometries, like nozzles or baffles. Trying to line these shapes with flat sheets requires numerous seams. Each seam is an edge—a built-in starting point for a peel to begin.

This is why chasing "better" adhesives is futile. You are fighting a battle against physics that you are destined to lose.

Beyond the Sheet: Choosing the Right PTFE Form Factor

To solve this problem permanently, you must move beyond the one-size-fits-all approach of sheet lining. The solution is to select a form of PTFE that is inherently immune to the failure mode. This requires a partner who understands not just the material, but its fabrication and application.

This is where the distinction between a material supplier and a fabrication specialist becomes critical. The right approach isn't to hope an adhesive sheet works; it's to engineer a solution based on a deep understanding of the root cause.

The Power of Precision: How Custom Fabrication Solves the Root Problem

As specialists in precision PTFE manufacturing, we see this challenge differently. The goal is to create a liner whose integrity doesn't depend on a thin layer of glue.

-

For High-Vacuum Applications: Instead of a thin, flexible sheet, the solution is often a thick, rigid, custom-machined PTFE liner. This liner can be designed to be self-supporting or to mechanically lock into the vessel. Its structural integrity comes from its own thickness and precise fit, not from an adhesive. It physically cannot be "peeled" off the wall by a vacuum.

-

For Complex Geometries: For a small, intricate vessel, the answer isn't to cut and paste dozens of small sheet pieces. The reliable solution is a single, custom-fabricated component machined from a solid block of PTFE. This completely eliminates seams, which are the primary failure points in complex, sheet-lined tanks.

This approach attacks the root of the problem. It replaces a failure-prone method (adhesion) with a mechanically robust solution (precision fabrication) designed for the specific stresses of the application.

From Preventing Failure to Enabling Innovation

When you engineer the right PTFE solution for your tank, you do more than just prevent costly failures. You unlock a new level of process capability and confidence.

With a mechanically sound liner, you can:

- Run Vacuum Processes: Safely operate processes that involve vacuum cycles for degassing, drying, or transfers, without any fear of liner delamination.

- Design More Efficient Vessels: Engineer smaller, more complex reactors with internal components, knowing they can be reliably lined with seamless, custom-fabricated PTFE.

- Increase Process Uptime: Move from a cycle of reactive repairs to predictable, long-term performance, guaranteeing the availability and purity of your process.

- Accelerate Innovation: Focus your engineering talent on optimizing your chemistry and products, not on fighting with unreliable equipment.

By matching the form and fabrication of your PTFE components to the real-world physics of your operation, you transform a chronic problem into a competitive advantage.

Stop letting the limitations of one-size-fits-all sheet lining dictate your process capabilities. If you're ready to engineer a permanent solution for your chemical containment challenges, our team of fabrication specialists is here to help you design the precise PTFE component your application demands. Let's discuss your project and ensure your next tank is built for lasting success. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Asymmetric Cost of Failure: Why Precision PTFE Is Your Last Line of Defense

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- The Engineer's Dilemma: Navigating the Trade-offs Between PTFE and Its Alternatives