It’s a scenario that’s both frustrating and familiar. A critical process line—handling high-purity chemicals or a sensitive pharmaceutical compound—is down. The cause? A leak at a flanged connection. You investigate, only to find the culprit is a PTFE gasket.

This is the one component you trusted to be invincible. PTFE is legendary for its near-universal chemical resistance and temperature stability. It shouldn’t fail. And yet, it has. Again.

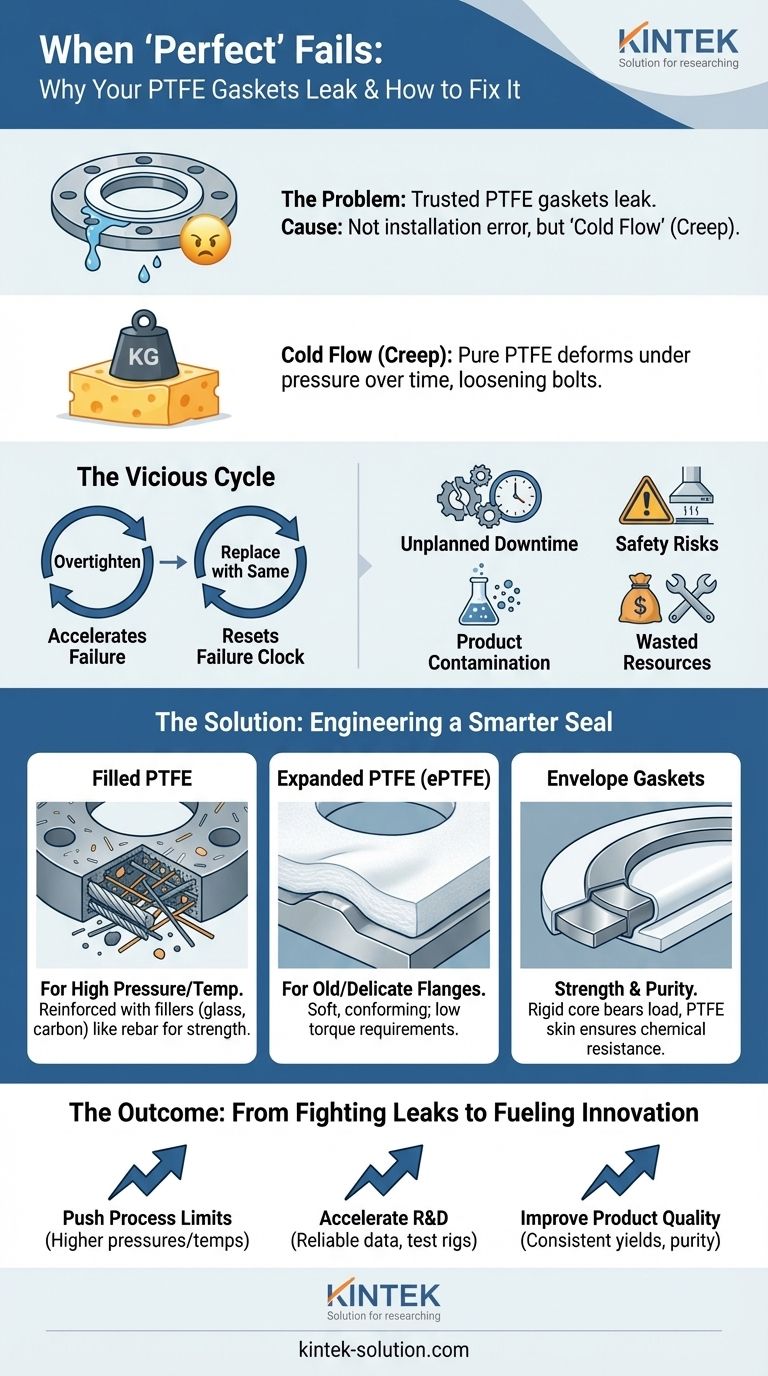

The Vicious Cycle of 'Fixing' the Seal

If this sounds familiar, you also know what comes next. The first assumption is usually installer error. "Maybe we didn't tighten the bolts enough," someone suggests. So, you replace the gasket and apply more torque. The seal holds... for a while. Then it leaks again.

The next time, the theory changes. "Maybe we overtightened it and crushed the gasket." So you replace it again, this time meticulously following torque specifications. The result is the same: a temporary fix followed by another inevitable failure.

This cycle of trial and error is more than just an operational headache. It has severe business consequences:

- Unplanned Downtime: Each failure brings a high-value process to a grinding halt, costing thousands in lost production.

- Product Contamination: In semiconductor, medical, or pharmaceutical applications, even a microscopic leak can compromise an entire multi-million dollar batch.

- Safety Risks: Leaks in aggressive chemical lines pose a direct threat to personnel and the environment.

- Wasted Resources: Engineering and maintenance teams spend their valuable time fighting recurring fires instead of optimizing processes or driving innovation.

You've tried everything—retorquing, replacing, and hoping—but the problem persists. That’s because these "fixes" are only addressing the symptom, not the root cause.

The Hidden Culprit: Unmasking 'Cold Flow'

The reason your "perfect" PTFE gaskets fail has little to do with installation and everything to do with a fundamental property of pure PTFE: creep, or cold flow.

Imagine placing a heavy weight on a block of hard cheese. Over time, even at room temperature, the cheese will slowly deform and "flow" outwards, away from the pressure.

Pure, or 'Virgin,' PTFE behaves in a similar way under the immense compressive force of a bolted flange. It slowly flows, thinning out where the pressure is greatest. As the gasket thins, the bolts lose their tension. A once-tight seal loses its compressive load, a microscopic gap forms, and a leak begins. This effect is only accelerated at higher temperatures.

This is why your standard troubleshooting fails:

- Overtightening a Virgin PTFE gasket only accelerates the cold flow, making the seal fail faster.

- Replacing it with another Virgin PTFE gasket simply resets the clock on the exact same failure mechanism.

You are not fighting a bad gasket; you are fighting the physics of the material itself.

The Right Tool for the Job: Engineering a Smarter Seal

To truly solve this problem, you don't need to abandon PTFE's incredible chemical resistance. You need to use a version of PTFE that has been specifically engineered to defeat cold flow under the mechanical stresses of your application.

This is where understanding the different types of PTFE gaskets moves from an academic exercise to a powerful problem-solving tool. They aren't just options; they are targeted solutions.

The Reinforcement: Filled PTFE

For systems with high pressure or temperature, Filled PTFE is the answer. By blending pure PTFE with reinforcing fillers like glass or carbon, we create a composite material. These fillers act like rebar in concrete, providing a rigid internal structure that physically resists deformation and cold flow. It gives you the chemical inertness you need, with the mechanical strength you demand.

The Conformist: Expanded PTFE (ePTFE)

What if you're sealing old, damaged, or delicate flanges, like those on glass-lined equipment? Here, high bolt torque is not an option. The solution is Expanded PTFE (ePTFE), a soft, marshmallow-like material. It is incredibly compressible, allowing it to conform to surface imperfections and create a tight seal with very low torque. It solves the problem by requiring far less force in the first place, thus reducing the stress that causes creep.

The Armored Core: Envelope Gaskets

For the ultimate combination of strength and purity, an Envelope Gasket is the ideal choice. This design features a rigid inner core (made of a material like stainless steel) wrapped in a thin "envelope" of pure PTFE. The strong core handles the high compressive load and prevents creep, while the PTFE envelope ensures that only the chemically inert material ever touches your process fluid.

At KINTEK, we see these not just as products, but as engineering solutions. Our expertise in precision fabrication allows us to help you diagnose the specific forces at play in your system and manufacture the exact PTFE component—from custom gaskets to liners and seals—that will deliver a reliable, long-lasting seal.

Beyond the Fix: From Fighting Leaks to Fueling Innovation

When you finally solve the persistent problem of gasket failure, the benefits extend far beyond simply stopping a leak. You unlock new potential across your operations.

Predictable, long-lasting seals mean you can shift from reactive maintenance to planned, extended service cycles. The risk of batch contamination vanishes, guaranteeing the integrity of your high-value products. Most importantly, your best engineers are freed from the recurring nightmare of troubleshooting leaks and can now focus on what they do best:

- Pushing Process Limits: Confidently run your systems at higher pressures and temperatures to increase throughput.

- Accelerating R&D: Build more reliable pilot plants and test rigs that produce consistent, trustworthy data.

- Improving Product Quality: Ensure process stability and purity, leading to higher yields and better end-products.

The right seal is more than a component; it's a catalyst for reliability and innovation. The challenges of cold flow, pressure, and temperature are complex, but the solution doesn't have to be a mystery. Our team doesn't just fulfill orders; we partner with you to solve your most demanding sealing challenges. Let's discuss the unique requirements of your project and engineer a solution that lasts. Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

Related Articles

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- How PTFE Solves Critical Industrial Challenges Through Material Superiority