The Illusion of Simplicity

A multi-million dollar satellite fails. A sterile bioreactor is contaminated. A semiconductor production line grinds to a halt. The culprit in these catastrophic failures is often not a complex electronic component, but a tiny polymer ring, costing only a few dollars.

This happens because we fall for a cognitive shortcut. We see a seal and think of it as a simple, passive component—a commodity. We treat a high-performance PTFE seal like a rubber O-ring, expecting it to just "work."

This is a fundamental misunderstanding. A PTFE seal is not a component; it is the visible part of an invisible, interconnected system. Its failure is rarely a failure of the seal itself, but a failure of the system as a whole.

The Three-Body Problem of Sealing

Achieving a reliable, long-lasting seal is a constant negotiation between three critical elements. Like a stable orbit, success depends on the perfect balance of forces between them. Ignoring one will send the entire system into chaos.

1. The Seal's Intrinsic Character: Material and Profile

The first element is the seal's own nature. This begins with the material choice, which defines its core capabilities.

- Virgin (Pure) PTFE: This is the diplomat, chosen for its unparalleled chemical inertness. In the pristine environments of pharmaceutical or semiconductor manufacturing, its purity is its greatest strength.

- Filled PTFE: This is the workhorse. By introducing fillers—carbon, glass, bronze—we enhance specific traits. These compounds gain immense wear resistance and resistance to "creep" (deformation under load), making them essential for high-pressure and dynamic applications.

The seal profile—the physical geometry of its lips and body—is its strategy. A V-ring, a U-cup, or a custom lip seal each has a different way of engaging with a surface, responding to pressure, and managing friction. The shape must be matched to the task.

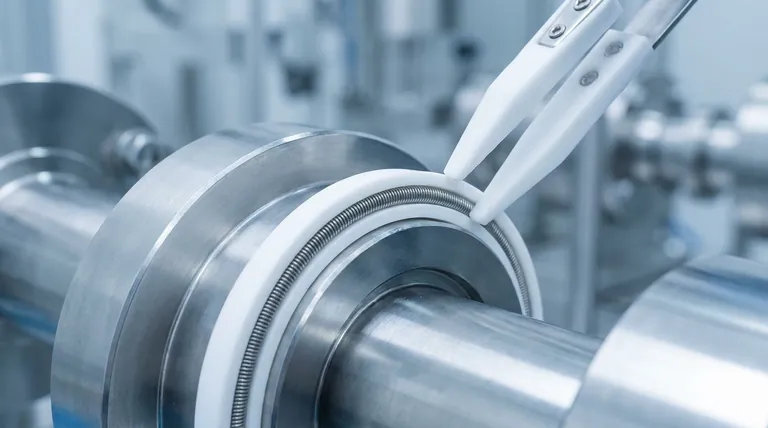

2. The Hidden Force: The Energizer

Here lies the most misunderstood aspect of a PTFE seal. Unlike elastic rubber, PTFE is a plastic. When compressed, it has very little "memory" or desire to spring back. It will hold its new, compressed shape.

This is why high-performance PTFE seals are energized.

Inside the PTFE jacket sits a spring (or sometimes an O-ring). This energizer is the seal's will. It provides a constant, active force, pushing the seal lips against the hardware. It is the mechanism that compensates for tiny imperfections, material creep, and the microscopic wear that occurs over millions of cycles.

The choice of energizer—a V-spring for high loads, a helical spring for wide temperature ranges—is as critical as the choice of PTFE itself. It is the soul of the machine.

3. The World It Inhabits: Hardware Design

You can specify the most advanced seal ever conceived, but it will fail instantly if its environment is hostile. The mating hardware is not a passive stage; it is an active participant in the sealing system.

Three hardware characteristics are paramount:

- Surface Finish: It's a delicate balance. Too rough, and the surface acts like sandpaper, abrading the seal lip. Too smooth, and it prevents a microscopic film of system media from forming, leading to high friction and heat.

- Hardness: The hardware must be significantly harder than the seal material, especially when using aggressive filled PTFE compounds. Otherwise, the hardware wears, not the seal, leading to catastrophic leaks.

- The Extrusion Gap: This is the tiny clearance between moving and static parts. Under high pressure, this gap becomes a weapon. If it's too large, the immense force will physically push the soft PTFE material into the gap, shredding it. This is a primary cause of failure in high-pressure hydraulic and pneumatic systems.

The Psychology of Failure: Overlooking the Obvious

The unique properties of PTFE introduce challenges that are often overlooked, not because they are complex, but because they seem mundane.

- The Installation Hurdle: PTFE is rigid. It cannot be stretched and rolled into a groove like rubber. Installation requires care, proper tools, and often hardware designed specifically to allow the seal to be installed without damage. A tiny scratch from a sharp thread during installation can create a leak path that dooms the application from day one.

- The Friction Fallacy: We hear "low friction" and think "no friction." But in high-speed applications, even PTFE's minimal friction generates heat. This thermal energy must be managed through lubrication or heat dissipation, or the seal material can exceed its temperature limits and fail.

Designing for Success

To build a reliable system, you must start with the right questions, guided by your primary challenge.

| Primary Challenge | System Design Focus |

|---|---|

| Extreme Chemical Resistance | Prioritize virgin PTFE or a compatible filled grade. Ensure the metal energizer (e.g., Hastelloy) is equally resistant to the aggressive media. |

| High-Pressure Containment | Obsess over the extrusion gap—make it as small as manufacturing allows. Select a robust seal profile with a high-force energizer to resist extrusion. |

| Dynamic or High-Wear Service | Use a filled PTFE compound. Critically specify and verify hardware surface finish and hardness to create a durable, low-friction pairing. |

True reliability doesn't come from a catalog part number. It comes from a holistic engineering approach that treats the seal, the energizer, and the hardware as one integrated system.

At KINTEK, we don't just manufacture components; we engineer solutions. We specialize in precision PTFE seals, liners, and custom parts for the most demanding semiconductor, medical, and industrial applications. We understand that success requires a partnership built on a deep understanding of your entire system. Let's design a solution that accounts for every variable. Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

Related Articles

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics