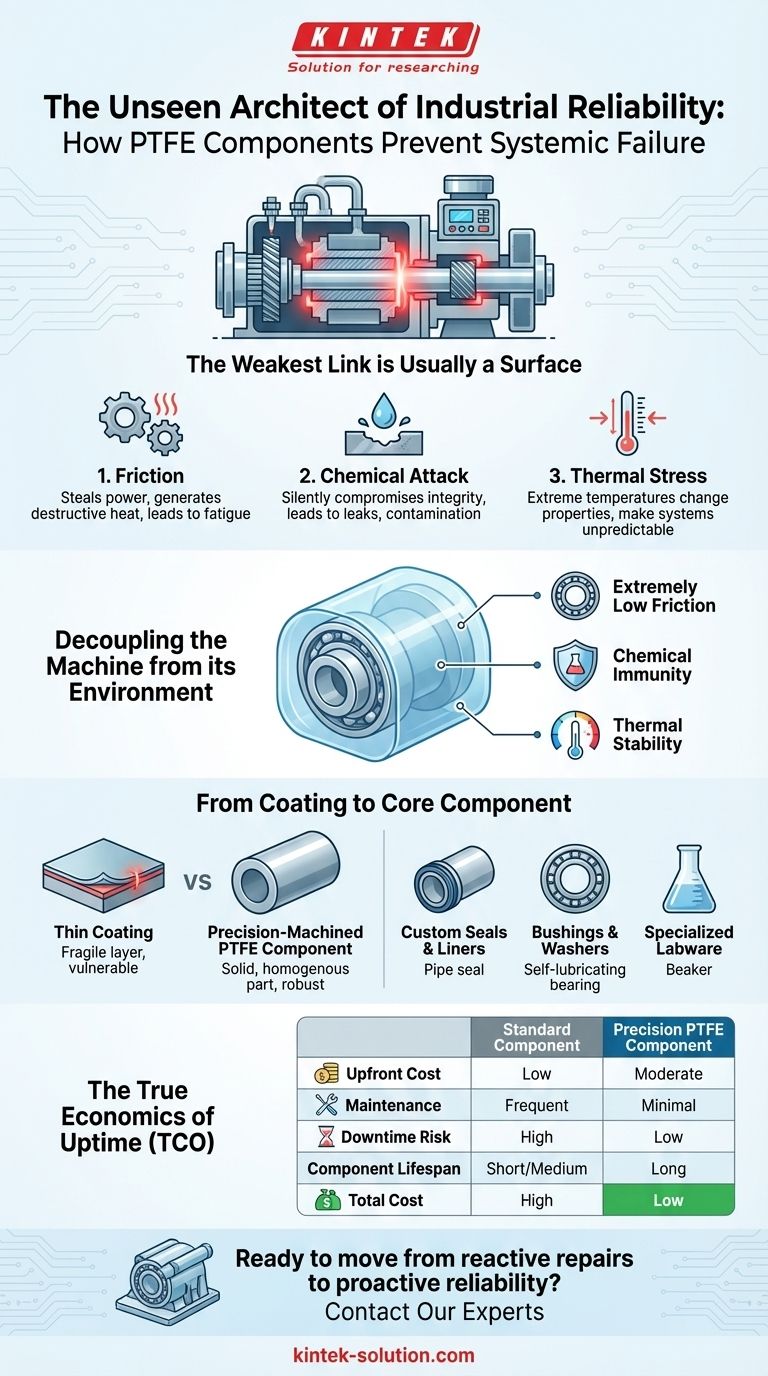

The Weakest Link is Usually a Surface

A catastrophic failure in a complex machine rarely begins with a loud bang. It starts silently, at the microscopic level, where two surfaces meet.

It’s the subtle friction in a bushing that generates just enough extra heat to degrade a lubricant. It’s the corrosive fluid that slowly, invisibly, compromises the integrity of a valve seat. It’s the thermal stress that causes a critical seal to lose its flexibility at the worst possible moment.

We tend to focus on the strength of large structures—the steel girders, the motor horsepower, the pressure ratings. But the long-term reliability of a system is almost always dictated by the integrity of its smallest, most vulnerable interfaces. The problem isn't the material of the machine; it's the environment the material is forced to endure.

The Three Forces of Mechanical Decay

Every mechanical system is in a constant battle against three invisible forces that relentlessly seek to degrade it. Understanding them is the first step to defeating them.

-

Friction: This is more than just wear and tear. It’s a constant tax on your system's energy. It steals power, generates destructive heat, and creates physical stress that leads to fatigue and failure.

-

Chemical Attack: Most strong, structural materials like steel are chemically reactive. In industrial processes, they are often exposed to acids, bases, or solvents that silently eat away at them, leading to leaks, contamination, and a catastrophic loss of integrity.

-

Thermal Stress: Extreme temperatures—both hot and cold—change the properties of materials. Metals expand, polymers can become brittle or melt. When a component cannot maintain its form and function under thermal load, the entire system becomes unpredictable and unsafe.

Decoupling the Machine from its Environment

The most elegant engineering solutions don't try to fight these forces with brute strength. Instead, they sidestep the conflict entirely.

This is the principle behind Polytetrafluoroethylene (PTFE), the material most famously known as Teflon. Its true value isn't just being "non-stick." In an industrial setting, its purpose is to decouple a component's structural material from its hostile operating environment.

By strategically placing PTFE at critical interfaces, you create an inert, low-friction, and thermally stable barrier. You insulate the core machinery from the very forces trying to destroy it.

The Power of an Inert Barrier

- Extremely Low Friction: PTFE has one of the lowest coefficients of friction of any solid. This drastically reduces mechanical wear on moving parts, lowers energy consumption, and minimizes heat generation—turning a maintenance liability into a predictable asset.

- Chemical Immunity: Being chemically inert, PTFE is virtually immune to corrosion. It doesn't react with acids, solvents, or bases. This allows you to use cost-effective structural metals for your machinery, knowing the surface in contact with the process fluid will not degrade.

- Thermal Stability: PTFE maintains its properties across a vast temperature range, from cryogenic lows to high-temperature industrial processes. This ensures components perform predictably, whether it's a seal in a liquid nitrogen line or a bushing in a high-temperature motor.

From Coating to Core Component

Applying a thin PTFE coating is a common solution, but it has limitations. A coating's performance is entirely dependent on its bond to the substrate, and it can be vulnerable to abrasive wear.

The most robust solutions are not applied to a part; they are the part.

This is where precision-machined PTFE components become the superior engineering choice. Instead of a fragile surface layer, you get a solid, homogenous component that embodies all the protective properties of the material.

At KINTEK, we specialize in fabricating these exact solutions. By moving beyond simple coatings to engineered components, we address the root cause of failure.

- Custom Seals and Liners: These create an unbreakable, chemically inert seal for pipelines, valves, and vessels, preventing leaks and protecting product purity in semiconductor or medical applications.

- Bushings and Washers: As solid, self-lubricating parts, they completely eliminate the need for grease in high-friction points. This creates a cleaner, lower-maintenance system that is less prone to failure from lubricant breakdown.

- Specialized Labware and Components: For industries where purity and reliability are paramount, custom-fabricated PTFE parts ensure that the equipment itself does not react with or contaminate the sensitive materials it handles.

The True Economics of Uptime

A specialized PTFE component may have a higher upfront cost than a standard metal part. This is where human psychology often leads us astray—we fixate on the immediate, visible cost.

The true calculation is the Total Cost of Ownership (TCO). The initial investment is weighed against the immense, often hidden, costs of failure.

| Metric | Standard Component | Precision PTFE Component |

|---|---|---|

| Upfront Cost | Low | Moderate |

| Maintenance | Frequent (lubrication) | Minimal (self-lubricating) |

| Downtime Risk | High (corrosion, seizure) | Low (inert, low-friction) |

| Component Lifespan | Short to Medium | Long |

| Total Cost | High | Low |

Investing in a precisely engineered component isn't a cost; it's the purchase of predictability. It's an investment in uptime, safety, and peace of mind.

By strategically upgrading the small, unseen parts that bear the brunt of friction, chemicals, and heat, you are not just fixing a machine. You are building a more resilient, reliable, and efficient system from the inside out.

Ready to move from reactive repairs to proactive reliability? Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

Related Articles

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics