It’s a familiar scene in any pulp and paper mill: a critical pump is down. Again. A seal has failed, leaking corrosive, abrasive slurry onto the floor, halting a production line and triggering another costly, unplanned maintenance call. You’ve tried everything—stronger materials, different suppliers, more frequent replacement schedules—but the problem always comes back. It feels like an unsolvable, expensive fact of life in the industry.

But what if it isn't? What if these chronic failures aren't random, but the predictable result of using the wrong tool for the job?

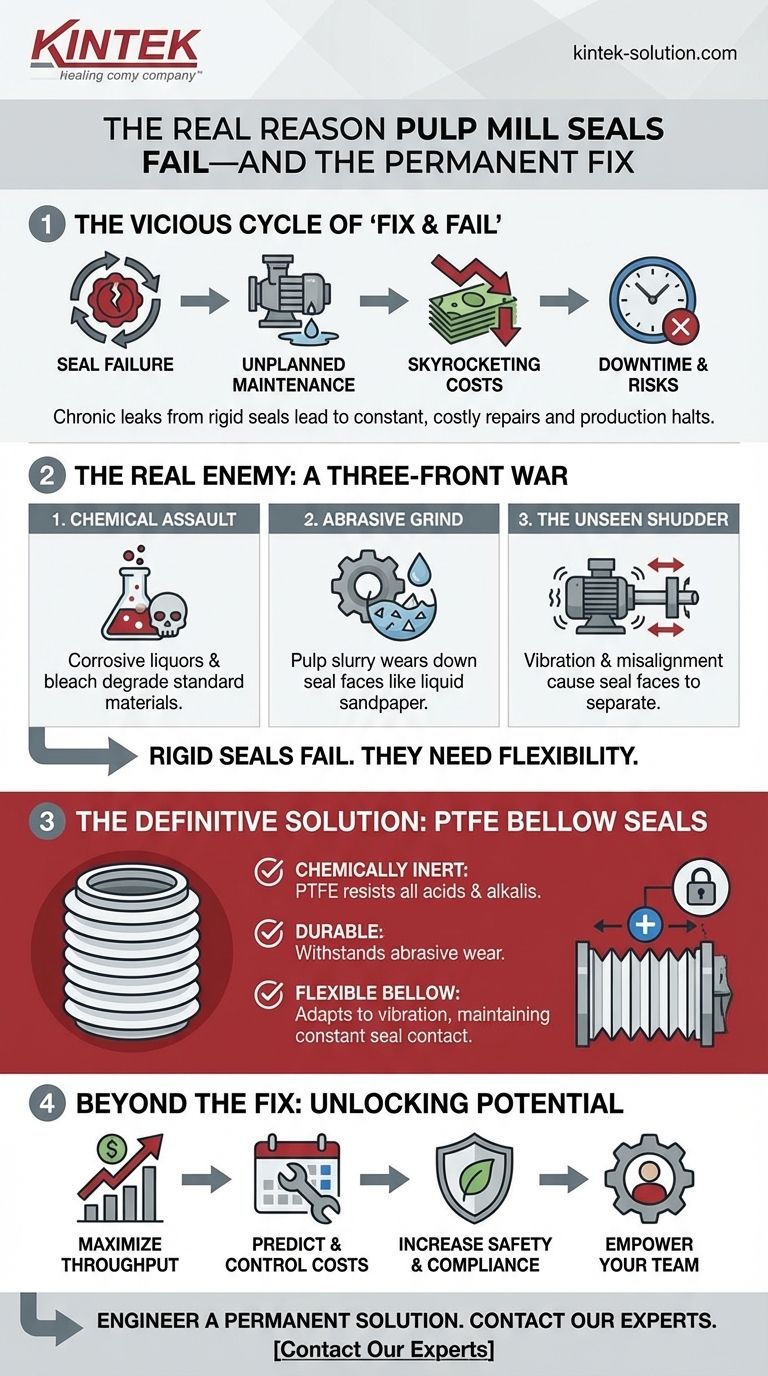

The Vicious Cycle of 'Fix and Fail'

For many plant and maintenance managers, dealing with seal failure is a constant, frustrating battle. When a seal on a stock pump, agitator, or chemical dosing unit leaks, the typical response is to replace it with what seems like a logical upgrade: a seal made from a harder elastomer or one with a more robust-looking design.

For a while, it might even seem to work. But soon enough, the leak returns. This cycle has severe business consequences that go far beyond the cost of a new seal:

- Skyrocketing Downtime Costs: Every hour a paper machine or pulp line is offline translates directly into thousands of dollars in lost production revenue.

- Bloated Maintenance Budgets: Constant emergency repairs drain your maintenance budget and pull your skilled technicians away from proactive, value-adding work.

- Safety and Environmental Risks: Leaks of hot, corrosive black liquor or bleaching agents create slip hazards and pose a direct threat to worker safety and environmental compliance. A single reportable spill can lead to heavy fines and reputational damage.

This isn't a problem of part quality; it's a fundamental mismatch between your equipment and the environment it operates in. Simply trying a "tougher" version of the same seal design is like bringing a stronger shield to a battle that requires agility.

The Real Enemy: A Three-Front War

The reason conventional seals are doomed to fail in a pulp and paper mill is that they are being attacked on three fronts simultaneously. A standard seal might be designed to handle one of these challenges, but almost none are built to withstand all three.

1. The Chemical Assault

The journey from wood chip to paper is a bath in aggressive chemicals. White, green, and black liquors, along with bleaching agents like chlorine dioxide, are highly corrosive. Most standard sealing materials, like common elastomers, will swell, soften, and chemically degrade when exposed to this environment, leading to inevitable failure.

2. The Abrasive Grind

Pulp slurry is not a gentle fluid. It’s a mixture of wood fibers, fillers, and liquid that acts like a constant stream of liquid sandpaper. This abrasive mixture rapidly wears down the precision-finished faces of a rigid mechanical seal, carving a path for leaks.

3. The Unseen Shudder

Large industrial machinery is never perfectly still. Pumps, mixers, and rollers all produce shaft vibration, radial movement, and slight misalignments. A rigid seal cannot compensate for this movement. The seal faces momentarily separate, allowing the abrasive slurry to get between them, which accelerates wear and causes a leak.

This is the crucial insight: your seals aren't failing because they're weak; they're failing because they are rigid in an environment that demands flexibility. The common "solutions" fail because they only address one symptom, not the three-pronged root cause.

A Seal Engineered for the Fight: The PTFE Bellow Solution

To win this three-front war, you don't need a stronger seal. You need a smarter seal, one engineered specifically for this complex challenge. It needs to be:

- Chemically inert to survive the corrosive attack.

- Durable enough to stand up to abrasion.

- Flexible enough to maintain a constant seal despite constant vibration and movement.

This is where a PTFE bellow seal becomes the definitive solution. Its design is not an accident; it is the physical embodiment of the answer to the pulp and paper industry's core sealing problem.

KINTEK's precision-engineered PTFE bellow seals directly neutralize all three threats:

- Against Chemicals: PTFE (Teflon) is one of the most chemically inert materials known. It does not react to the harsh acids and alkalis in your process, ensuring it won't degrade, swell, or weaken over time.

- Against Abrasion & Movement: This is the genius of the bellow design. Unlike a rigid seal, the flexible, accordion-like bellow acts like a spring. It allows the seal face to dynamically adjust to shaft vibration and misalignment, ensuring the sealing surfaces remain in constant, positive contact. This locks out the abrasive slurry and maintains a perfect seal, even on equipment that shudders and moves.

By choosing a component specifically designed for the true nature of the problem, you move from a reactive cycle of failure to a proactive state of control.

Beyond the Fix: Unlocking New Operational Potential

When you solve chronic seal failure, you do more than just stop leaks. You fundamentally change what's possible for your operations.

With reliable, long-lasting seals, you can:

- Maximize Throughput: Run production lines for longer, uninterrupted periods with the confidence that your equipment will perform.

- Predict and Control Costs: Shift your maintenance budget from unpredictable emergency repairs to planned, preventative activities.

- Increase Safety & Compliance: Eliminate a major source of hazardous spills, creating a safer workplace and ensuring you meet or exceed environmental regulations.

- Empower Your Team: Free your skilled maintenance professionals to focus on optimizing equipment and improving plant efficiency, rather than constantly fighting fires.

It’s the shift from asking, "How do we keep this from breaking?" to "How can we optimize our output?"

Solving chronic seal failure is more than a maintenance task; it's a strategic move that directly impacts your plant's profitability, safety, and long-term reliability. If the challenges described here resonate with your operations, it's time for a conversation about a permanent solution. Our experts are ready to understand your specific equipment and process challenges to engineer a PTFE component that delivers lasting performance. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

Related Articles

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good