PTFE gaskets are critical components in industries where chemical resistance, temperature stability, and long-term sealing performance are non-negotiable. Yet, their durability hinges on proper installation—a process often underestimated. This guide explores the essential protocols to maximize PTFE gasket lifespan and prevent costly operational failures.

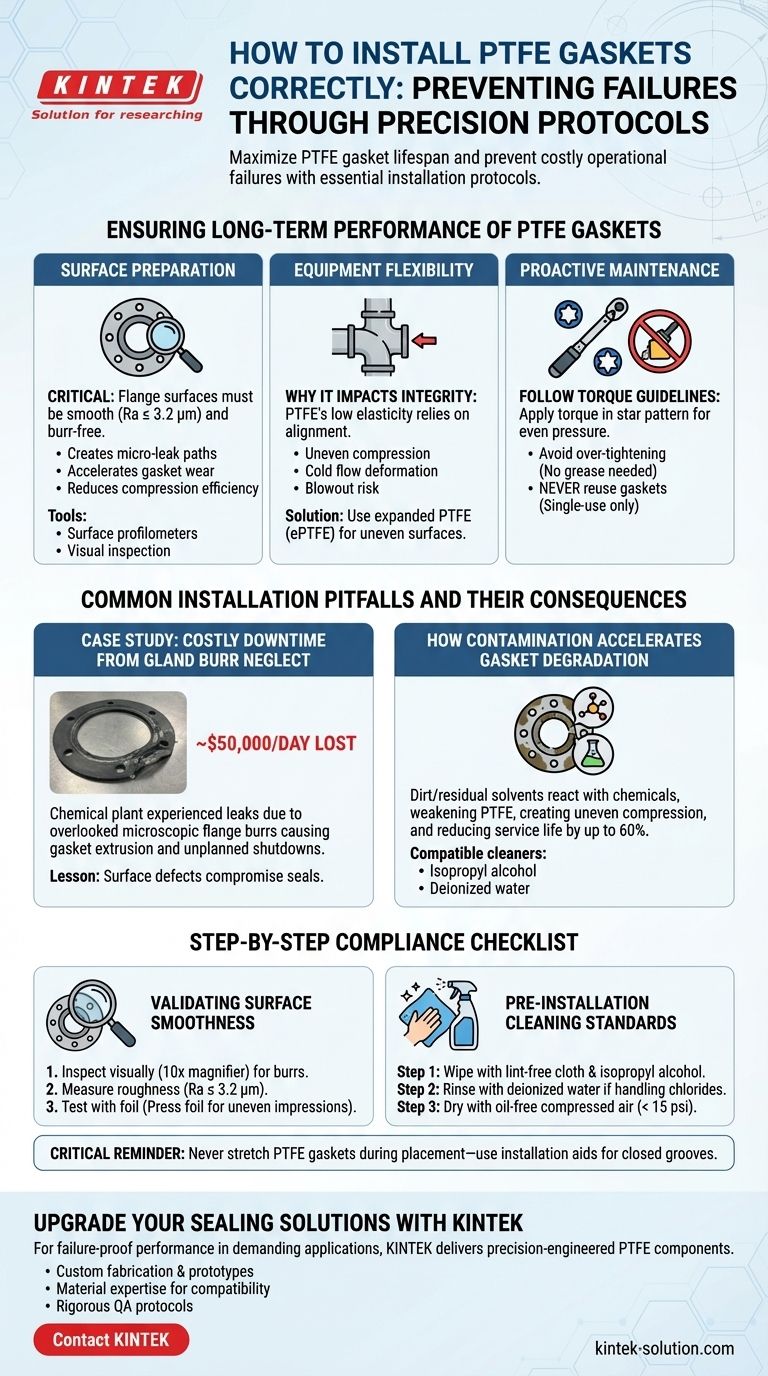

Ensuring Long-Term Performance of PTFE Gaskets

PTFE gaskets excel in harsh environments, resisting temperatures from -200°C to 400°C and corrosive chemicals. However, their performance depends on three foundational installation principles:

The Critical Role of Surface Preparation

Flange surfaces must be smooth and free of burrs or debris. Even minor imperfections can:

- Create micro-leak paths

- Accelerate gasket wear

- Reduce compression efficiency

Tools for validation:

- Surface profilometers (for roughness checks)

- Visual inspection under bright light

Why Equipment Flexibility Impacts Seal Integrity

PTFE’s low elasticity means it relies on proper flange alignment. Misalignment can:

- Cause uneven compression

- Lead to cold flow (permanent deformation)

- Increase the risk of blowouts

Solution: Use expanded PTFE (ePTFE) gaskets for uneven surfaces—they require less torque and adapt better to irregularities.

Proactive Maintenance Through Proper Installation

Follow these torque and compression guidelines:

- Apply torque in a star pattern to distribute pressure evenly

- Avoid over-tightening (PTFE doesn’t require grease due to low friction)

- Never reuse a gasket—cold flow makes them single-use

Common Installation Pitfalls and Their Consequences

Case Study: Costly Downtime from Gland Burr Neglect

A chemical plant experienced repeated leaks in a sulfuric acid line. Investigation revealed:

- Microscopic flange burrs (overlooked during inspection)

- Gasket material extruding into gaps over time

- Unplanned shutdowns costing ~$50,000/day

Lesson: Surface defects, even invisible ones, compromise seals.

How Contamination Accelerates Gasket Degradation

Dirt or residual solvents between flanges can:

- React with process chemicals, weakening PTFE

- Create uneven compression zones

- Reduce service life by up to 60%

Compatible cleaners:

- Isopropyl alcohol (for most contaminants)

- Deionized water (for salt deposits)

Step-by-Step Compliance Checklist

Validating Surface Smoothness (Tools & Methods)

- Inspect visually: Use a 10x magnifier to detect burrs.

- Measure roughness: Ensure Ra (average roughness) is ≤ 3.2 µm.

- Test with foil: Press aluminum foil onto the flange—uneven impressions reveal high spots.

Pre-Installation Cleaning Standards for Chemical Resistance

- Step 1: Wipe with lint-free cloth soaked in isopropyl alcohol.

- Step 2: Rinse with deionized water if handling chlorides.

- Step 3: Dry with oil-free compressed air (< 15 psi).

Critical reminder: Never stretch PTFE gaskets during placement—use installation aids for closed grooves.

Upgrade Your Sealing Solutions with KINTEK

PTFE gaskets are only as reliable as their installation. For industries where failure isn’t an option—semiconductor cleanrooms, medical sterilization systems, or corrosive chemical processing—KINTEK’s precision-engineered PTFE components deliver unmatched performance.

Why choose KINTEK?

- Custom fabrication from prototypes to high-volume orders

- Material expertise ensuring compatibility with your specific media

- Rigorous QA protocols mirroring aerospace standards

Ensure your next installation is failure-proof. [Contact KINTEK] for gaskets designed to outlast your most demanding applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

Related Articles

- Your "Inert" PTFE Component Might Be the Real Source of System Failure

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- How PTFE Solves Critical Industrial Challenges Through Material Superiority