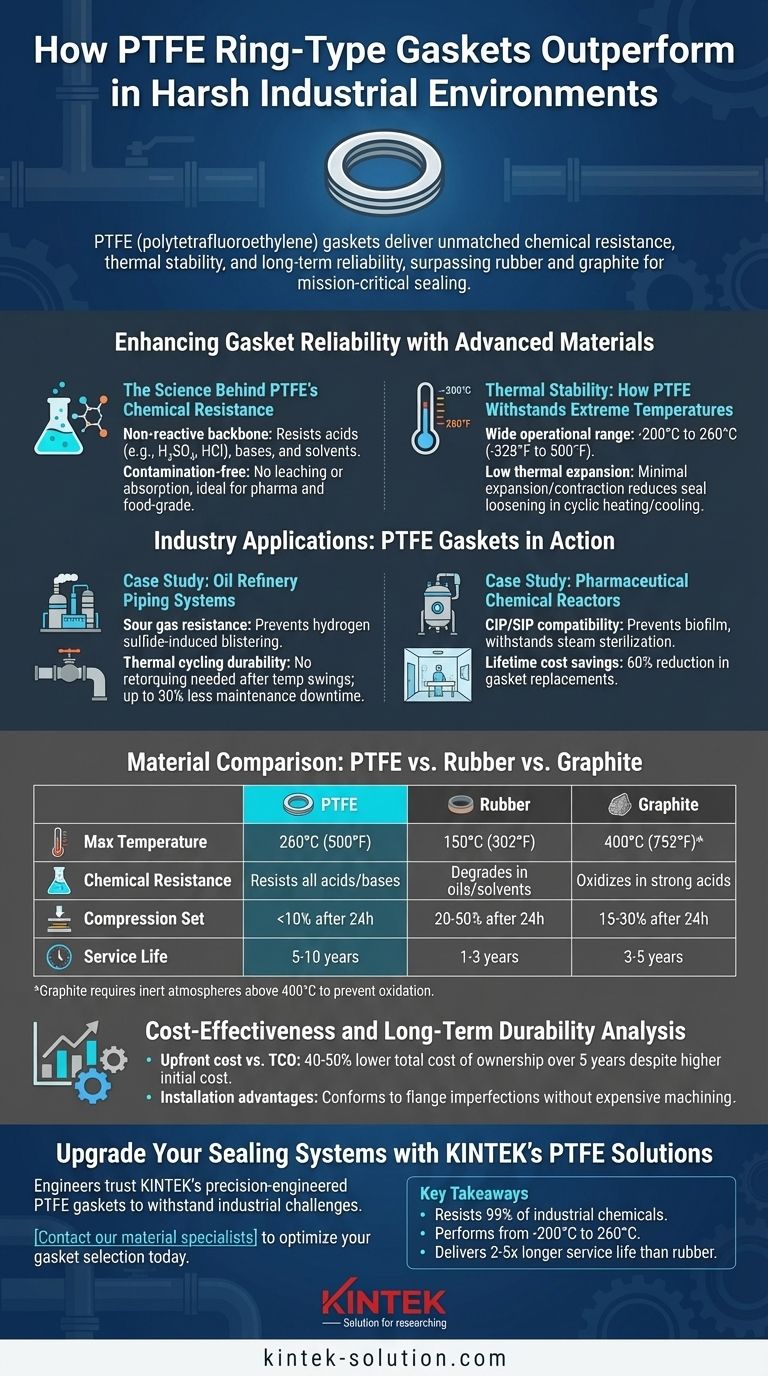

When sealing systems face corrosive chemicals, extreme temperatures, or demanding operational cycles, material selection becomes critical. PTFE (polytetrafluoroethylene) ring-type gaskets consistently outperform alternatives like rubber or graphite by combining unmatched chemical resistance, thermal stability, and long-term reliability. Here’s why industries from oil refineries to pharmaceutical plants rely on PTFE for mission-critical sealing.

Enhancing Gasket Reliability with Advanced Materials

PTFE’s molecular structure delivers inherent properties that address the top failure modes of industrial gaskets: chemical degradation, thermal stress, and mechanical wear.

The Science Behind PTFE’s Chemical Resistance

- Non-reactive backbone: PTFE’s carbon-fluorine bonds are among the strongest in organic chemistry, resisting attacks from acids (e.g., sulfuric, hydrochloric), bases, and solvents. Research shows PTFE labware remains intact even when exposed to highly concentrated corrosive agents.

- Contamination-free performance: Unlike rubber or graphite, PTFE doesn’t leach additives or absorb process fluids, making it ideal for pharmaceutical and food-grade applications where purity is paramount.

Thermal Stability: How PTFE Withstands Extreme Temperatures

- Wide operational range: PTFE maintains structural integrity from cryogenic conditions (-200°C/-328°F) to sustained high heat (260°C/500°F), outperforming rubber (max ~150°C/302°F) and graphite (prone to oxidation above 400°C/752°F).

- Low thermal expansion: PTFE’s minimal expansion/contraction under temperature fluctuations reduces the risk of seal loosening—a common issue with elastomers in cyclic heating/cooling applications.

Industry Applications: PTFE Gaskets in Action

Case Study: Oil Refinery Piping Systems

In refinery environments, PTFE ring gaskets solve two critical challenges:

- Sour gas resistance: PTFE seals prevent hydrogen sulfide-induced blistering, a failure point for metal-reinforced rubber gaskets.

- Thermal cycling durability: Unlike graphite, PTFE doesn’t require retorquing after temperature swings, reducing maintenance downtime by up to 30% in flange connections.

Case Study: Pharmaceutical Chemical Reactors

- CIP/SIP compatibility: PTFE’s non-stick surface prevents biofilm buildup during clean-in-place (CIP) cycles, while its steam resistance (up to 150°C/302°F at 4 bar) ensures sterility in steam-in-place (SIP) systems.

- Lifetime cost savings: One pharmaceutical plant reported a 60% reduction in gasket replacements after switching from EPDM to PTFE in reactor lid seals.

Material Comparison: PTFE vs. Rubber vs. Graphite

| Property | PTFE | Rubber | Graphite |

|---|---|---|---|

| Max Temperature | 260°C (500°F) | 150°C (302°F) | 400°C (752°F)* |

| Chemical Resistance | Resists all acids/bases | Degrades in oils/solvents | Oxidizes in strong acids |

| Compression Set | <10% after 24h | 20-50% after 24h | 15-30% after 24h |

| Service Life | 5-10 years | 1-3 years | 3-5 years |

*Graphite requires inert atmospheres above 400°C to prevent oxidation.

Cost-Effectiveness and Long-Term Durability Analysis

- Upfront cost vs. TCO: While PTFE gaskets cost 2-3x more than rubber equivalents, their 3x longer lifespan and reduced downtime lead to 40-50% lower total cost of ownership over 5 years.

- Installation advantages: Expanded PTFE variants conform to flange imperfections without requiring expensive surface machining—a key benefit over rigid graphite.

Upgrade Your Sealing Systems with KINTEK’s PTFE Solutions

Engineers trust KINTEK’s precision-engineered PTFE gaskets to withstand the toughest industrial challenges while reducing lifecycle costs. Whether you’re sealing aggressive chemicals in semiconductor fabs or high-temperature steam lines, our custom formulations balance performance with reliability. [Contact our material specialists] to optimize your gasket selection today.

Key Takeaways

- PTFE’s molecular structure provides inherent resistance to 99% of industrial chemicals.

- Performs across -200°C to 260°C without losing sealing force.

- Delivers 2-5x longer service life than rubber in corrosive applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

Related Articles

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- How PTFE Solves Critical Industrial Challenges Through Material Superiority