You’ve done everything by the book. The flange faces are clean, the bolts are torqued to spec, and the system is ready. But hours or days into a critical process, you see it: the slow, tell-tale drip of a failed seal. It’s a frustratingly common story in labs and industrial plants everywhere, a small failure that can bring an entire operation to a halt.

The Vicious Cycle: Chasing Leaks with the Wrong Solutions

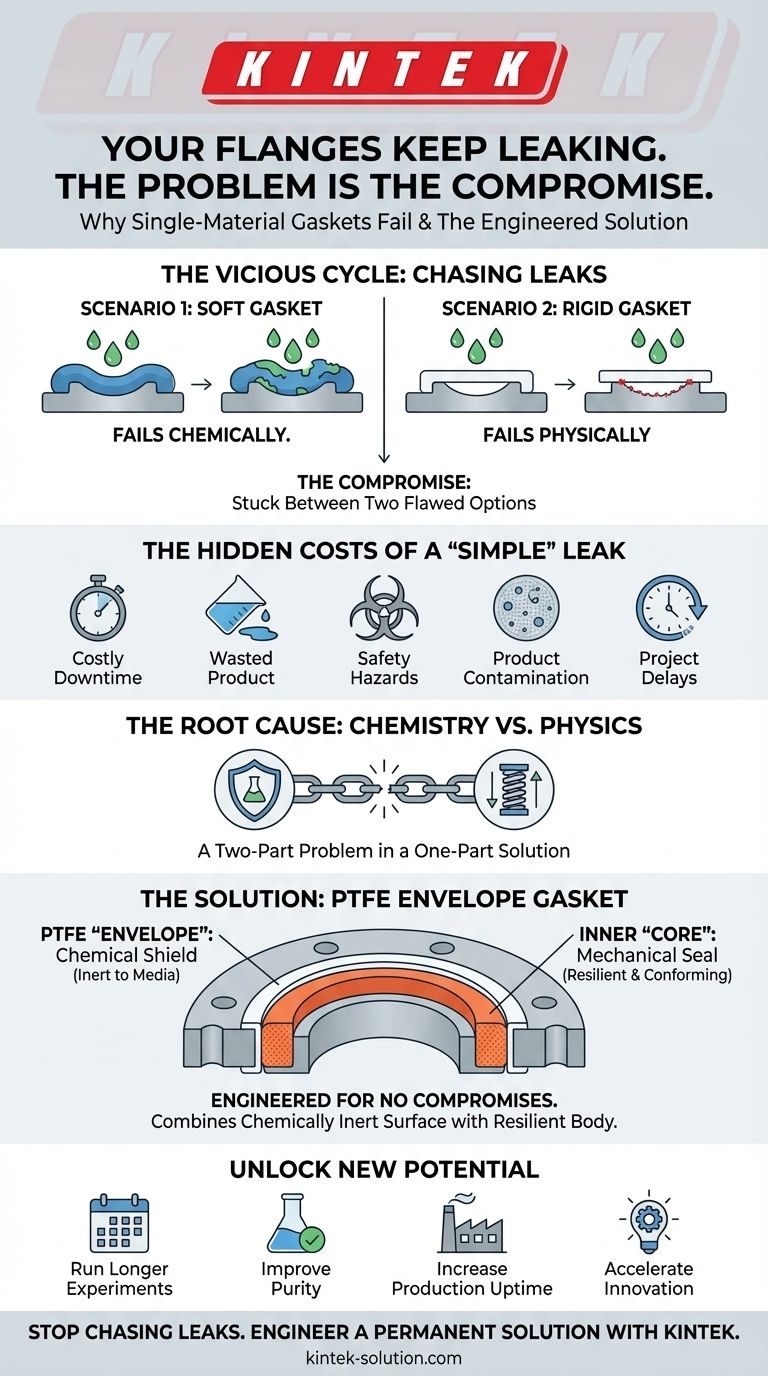

When a seal fails, the troubleshooting cycle begins. This process is often a frustrating journey of trial and error, forcing you to choose between two seemingly logical but ultimately flawed options.

Scenario 1: You choose a soft, compressible gasket. Your first thought might be that the flange surfaces aren't perfectly flat. A soft rubber or elastomer gasket seems like the perfect fix. It compresses beautifully, filling in every minor scratch and warp to create an initially tight seal. But if your process involves aggressive chemicals, acids, or solvents, this gasket soon becomes the weak link. The material swells, hardens, or dissolves. The seal is compromised, and the leak returns.

Scenario 2: You choose a chemically bulletproof gasket. Learning from the last failure, you switch to a solid PTFE gasket. Polytetrafluoroethylene is famous for its near-universal chemical immunity. It won't degrade. The problem? Solid PTFE is also rigid. It lacks the "forgiveness" to conform to the microscopic imperfections found on virtually all real-world flange surfaces. While it survives the chemicals, it fails to create a perfect mechanical seal. A tiny gap remains, and under pressure, it begins to leak.

You are stuck. One gasket solves the chemical problem but fails the physical one; the other solves the physical problem but fails the chemical one.

The Hidden Costs of a 'Simple' Leak

This isn't just a maintenance headache; it's a significant business problem. Each failed seal can lead to:

- Costly Downtime: Shutting down a production line or a long-term experiment for repairs.

- Wasted Product: Loss of valuable chemicals, reagents, or final products.

- Safety Hazards: Leaks of corrosive or hazardous materials pose a direct risk to personnel and the environment.

- Product Contamination: A failing seal can shed particles, compromising purity in sensitive applications like semiconductor or pharmaceutical manufacturing.

- Project Delays: Repeated failures push back timelines for R&D and production, slowing innovation and time-to-market.

The Real Culprit: A Battle Between Chemistry and Physics

The reason for this cycle of failure is not the quality of the gaskets themselves. The root cause is that you've been forced to solve a two-part problem with a one-part solution.

A reliable, long-term seal in a demanding application must do two things simultaneously:

- Survive the Chemistry: It must be completely inert to the process media flowing through the pipes.

- Master the Physics: It must be soft and pliable enough to compress and flow into the microscopic "hills and valleys" of the flange faces, creating a leak-proof mechanical barrier.

Single-material gaskets force a compromise. The materials that excel at mastering the physics (like elastomers) are often vulnerable to chemistry. The materials that are impervious to chemistry (like solid PTFE) are often too rigid to master the physics of sealing imperfect surfaces. Your leak isn't a material failure; it's a design compromise.

The Solution: Stop Compromising, Start Combining

To permanently solve this problem, you don't need a "better" single material. You need a smarter design that refuses to compromise. You need a solution that combines a chemically inert surface with a resilient, compressible body.

This is precisely the principle behind the PTFE envelope gasket. It's not just another gasket; it's an engineered solution to this fundamental conflict.

The PTFE Envelope Gasket: Engineered for No Compromises

This hybrid design provides the best of both worlds by assigning each job to a specialized component:

- The PTFE "Envelope": A thin, pure PTFE shell is the only part that touches your process media. It acts as an impenetrable chemical shield, providing the universal resistance you need while ensuring a non-stick, non-contaminating surface.

- The Inner "Core": Inside this shield sits a compressible, resilient core material (like non-asbestos fiber or an elastomer). This core doesn't need to resist chemicals—it's fully protected. Its only job is to provide the mechanical force and flexibility to create a perfect, void-free seal, even on flanges that aren't perfectly flat.

At KINTEK, we specialize in fabricating these components with extreme precision. We understand that for this system to work, the fit and quality of both the envelope and the core must be perfect. Our PTFE envelope gaskets are not just parts; they are the direct result of understanding why other seals fail and engineering a solution that addresses the root cause.

Beyond the Fix: What's Possible with a Truly Reliable Seal?

When you stop fighting persistent leaks, you unlock new potential. This isn't just about preventing downtime; it's about enabling progress. With a seal you can finally trust, you can:

- Run Longer, More Ambitious Experiments: In the lab, you can confidently run tests for weeks or months without fear of seal degradation or contamination.

- Improve Product Purity and Yield: In semiconductor or pharmaceutical manufacturing, you can maintain ultra-pure process environments, leading to higher quality and less waste.

- Increase Production Uptime: In industrial settings, you can extend maintenance cycles, reduce shutdowns, and run your lines more efficiently and safely.

- Accelerate Innovation: By eliminating a common point of failure, your engineering and R&D teams can focus on core challenges, bringing new products and processes to market faster.

Fixing a persistent leak is more than just a maintenance win; it's a strategic advantage that enhances reliability, purity, and safety across your entire operation. If you're tired of chasing temporary fixes for your critical sealing applications, our team is ready to help you engineer a permanent solution. Let's discuss the unique challenges of your project and find the right approach together. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure