It’s a familiar and frustrating scenario for any plant or lab manager. A critical flanged connection, one that was just serviced weeks ago, is showing the tell-tale signs of a leak. Whether it's a visible drip, a subtle chemical scent, or an alert from a pressure sensor, the result is the same: another unplanned shutdown, another maintenance order, and another blow to your operational schedule. You check the torque on the bolts, you schedule a replacement, and you wonder why this keeps happening.

Chasing Symptoms: Why Retightening and Replacing Aren't Working

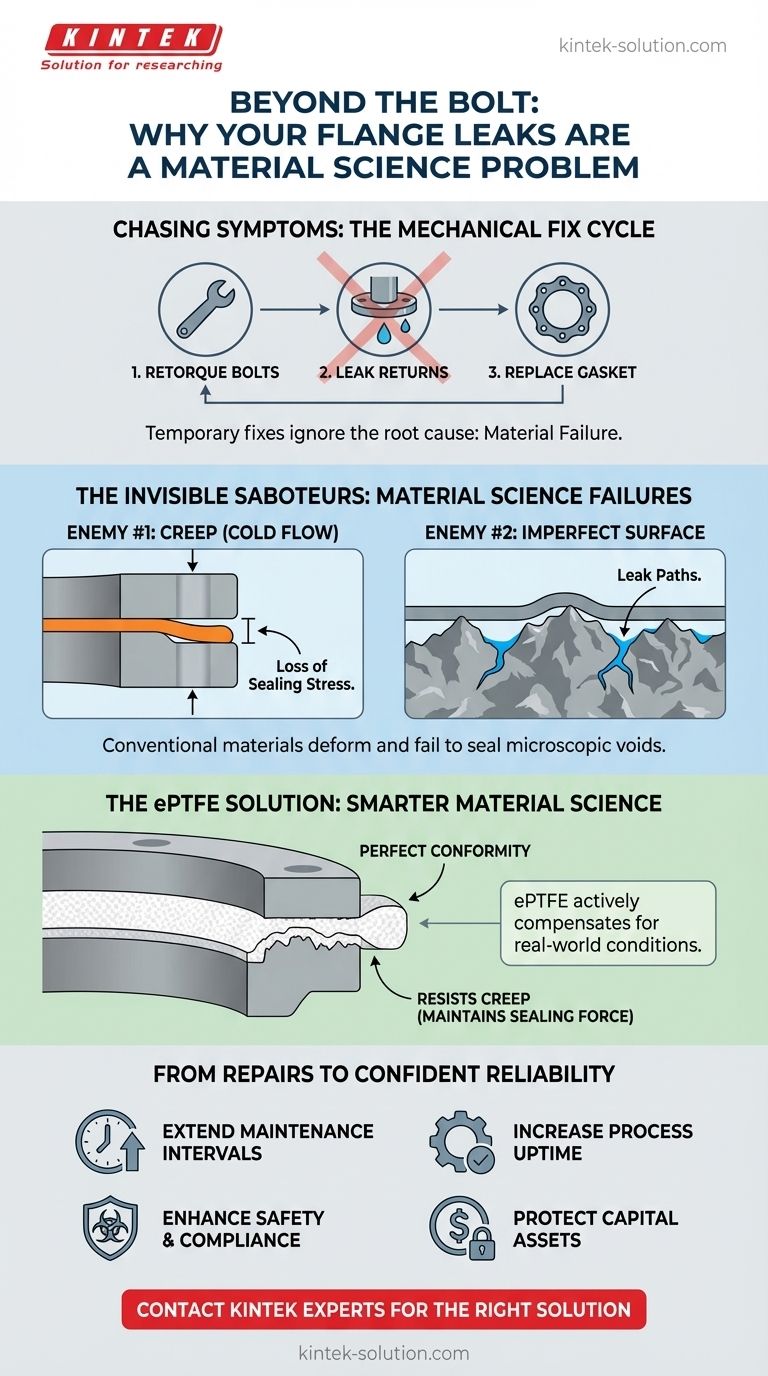

When a flange leaks, our instincts tell us it's a mechanical problem. The common response is a cycle of reactive fixes:

- Retorque the Bolts: The first step is always to apply more force. This might stop the leak for a few hours or a few days, but it’s rarely a permanent solution. The leak almost always returns.

- Replace the Gasket: The next step is to schedule downtime, pull the system apart, and install a new gasket—often the exact same type that just failed.

- Inspect the Flanges: If the problem persists, you might even resurface the flange faces, assuming they are warped or damaged.

This cycle of "tighten, replace, repeat" treats the symptom—the leak—but completely ignores the underlying disease. The business consequences are significant and compounding. Every instance means costly downtime, wasted maintenance hours, potential safety hazards from hazardous materials, and the risk of product contamination. Over time, slow, corrosive leaks can permanently damage expensive flange assets, turning a small problem into a capital expenditure.

The Invisible Saboteurs: Meet Creep and the Imperfect Surface

What if the problem isn't your bolts, your flanges, or your installation procedure? What if the conventional gasket material itself is designed to fail in this exact way over time? The root cause of most recurring flange leaks isn't a single event, but a slow-motion failure driven by two invisible material science principles.

Enemy #1: Creep (or Cold Flow)

Imagine squeezing a piece of modeling clay between your palms. Under constant pressure, it slowly deforms and spreads outward. Many standard gasket materials behave in the exact same way. This phenomenon is called creep or cold flow. From the moment you tighten the bolts, the gasket material begins to slowly "flow" out from between the flanges. This process reduces the sealing stress, creating microscopic pathways for leaks to begin. Retightening the bolts is just a temporary fix because it can’t stop the material itself from continuing to deform.

Enemy #2: The Imperfect Surface

Under a microscope, even a perfectly machined and polished metal flange face looks like a rugged mountain range. It’s covered in microscopic peaks, valleys, scratches, and voids. Rigid or conventional gaskets can't flow into every single one of these imperfections. They bridge the gaps, leaving behind a network of tiny, invisible tunnels. While it may pass a pressure test initially, these tunnels are the highways where leaks are born, especially as temperature and pressure fluctuations cause the flanges to expand and contract.

The common "solutions" fail because they don't address these two fundamental material failures. You can't tighten a bolt hard enough to stop a material that is determined to creep.

Fighting Material Failure with Material Science: The ePTFE Solution

To win this battle, you don't need more force; you need smarter material. You need a gasket that is engineered to defeat creep and perfectly conform to real-world surfaces. This is precisely what Expanded Polytetrafluoroethylene (ePTFE) is designed to do.

An ePTFE gasket isn't just a passive seal; it's an active component that solves the root problems of leakage:

- It Conforms Perfectly: The unique, soft microstructure of ePTFE allows it to flow like a viscous liquid under compression. It fills every microscopic scratch, pit, and valley on the flange face, creating a void-free, perfect initial seal that eliminates leak paths from the start.

- It Resists Creep: Unlike conventional materials, the fibrous structure of ePTFE provides exceptional creep resistance. It maintains its shape and density under sustained load and thermal cycling. This means it continues to exert a consistent, reliable sealing force—what engineers call "spring back"—long after other materials would have failed. It stays put and keeps the seal tight.

A KINTEK ePTFE gasket isn't just a replacement part; it's a strategic upgrade. It is a solution designed from a deep understanding of why seals really fail, offering a direct countermeasure to the invisible forces that cause chronic leaks.

From Constant Repairs to Confident Reliability

Once you solve the root cause of persistent leaks, you fundamentally change how you operate. The cycle of reactive maintenance ends, unlocking new potential and allowing your team to focus on proactive improvements rather than constant firefighting.

By installing a seal that actively compensates for real-world conditions, you can:

- Dramatically Extend Maintenance Intervals: Move from a schedule of frequent, unplanned repairs to predictable, long-term reliability.

- Increase Process Uptime: Run your critical systems with the confidence that your connections will hold, maximizing output and efficiency.

- Enhance Safety and Compliance: Securely contain aggressive or hazardous media, protecting your personnel and the environment.

- Protect Capital Assets: Prevent the slow, corrosive damage that degrades expensive flange assemblies over time.

Solving this persistent problem isn't just about stopping a drip. It's about building a more robust, reliable, and profitable operation. If you're ready to move beyond temporary fixes and address the true source of your sealing challenges, our team of material science experts can help you specify the right solution for your unique application. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

Related Articles

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems