In short, PTFE is widely used in the medical device industry because it is exceptionally biocompatible, chemically inert, and has an extremely low-friction surface. This unique combination of properties ensures that devices made from it are safe for patient contact, do not degrade when exposed to bodily fluids or aggressive sterilization processes, and can move smoothly within the body or in mechanical assemblies.

The core reason for PTFE's prevalence is its duality: it is one of the most biologically inert materials known, preventing adverse reactions inside the body, while also being physically robust enough to handle the demanding chemical and mechanical environments of modern medicine.

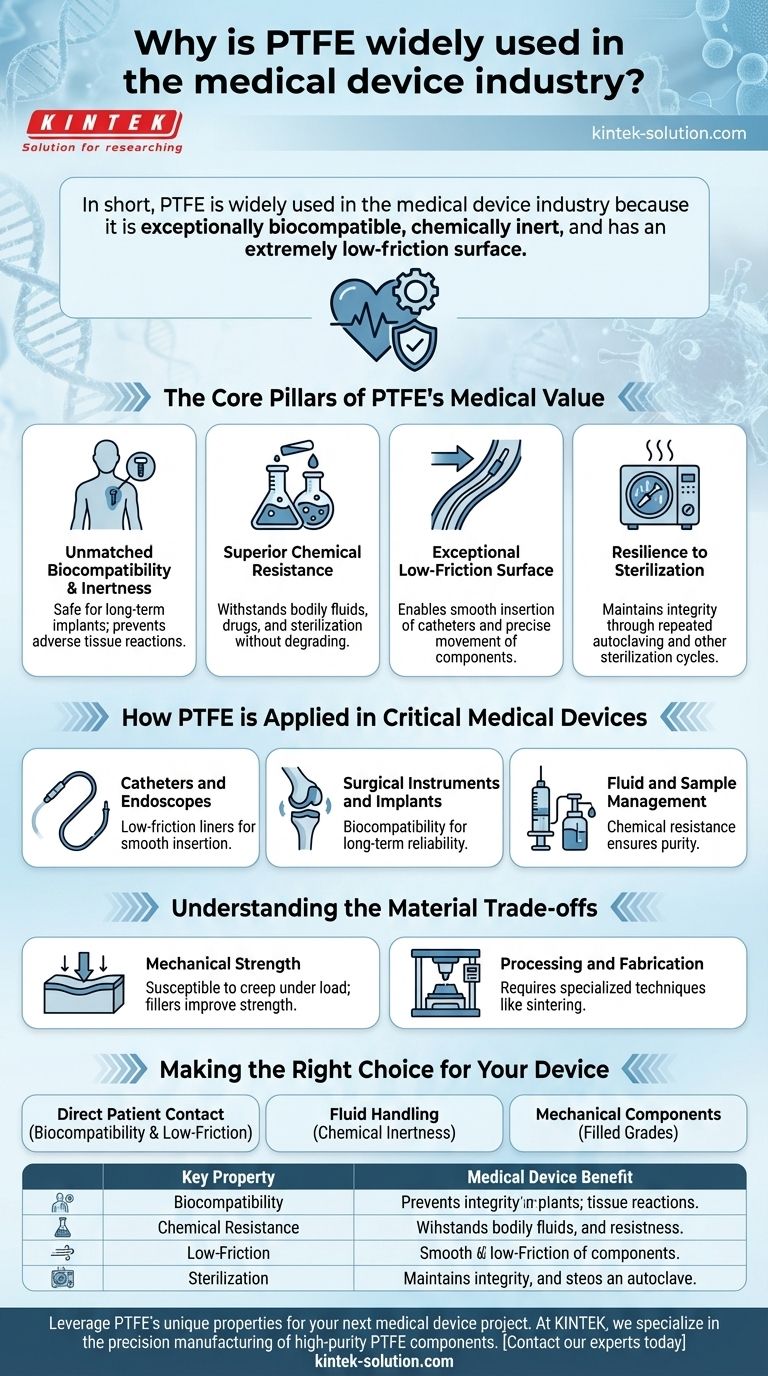

The Core Pillars of PTFE's Medical Value

To understand why PTFE (polytetrafluoroethylene) is a go-to material, we must examine the specific properties that make it uniquely suited for clinical applications. These attributes address the fundamental requirements of safety, reliability, and performance.

Unmatched Biocompatibility and Inertness

PTFE is non-toxic and causes virtually no reaction when it comes into contact with human tissue or fluids. This makes it an ideal material for implants, surgical patches, and other devices that reside within the body for extended periods.

Its inert nature ensures the material itself does not break down or leach harmful substances, protecting the patient from potential complications.

Superior Chemical Resistance

Medical environments are chemically harsh, involving bodily fluids, aggressive cleaning agents, and various pharmaceuticals. PTFE is resistant to nearly all chemicals and solvents.

This property guarantees that components like seals, tubing, and fluid management systems will not corrode or degrade, maintaining the integrity and purity of the substances they transport.

Exceptional Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material, giving it a "non-stick" quality. This is critical for devices that must navigate delicate internal pathways.

For example, catheters with PTFE liners slide smoothly through blood vessels, minimizing tissue damage and discomfort during minimally invasive procedures. This also benefits mechanical parts like syringe plungers, ensuring smooth and precise operation.

Resilience to Sterilization

Medical devices, especially those that are reusable, must withstand repeated sterilization cycles without losing their properties.

PTFE is stable at high temperatures, allowing it to easily handle common methods like steam autoclaving. This ensures that instruments remain sterile and safe for use on multiple patients.

How PTFE is Applied in Critical Medical Devices

These fundamental properties translate directly into solutions for a wide range of medical challenges, making PTFE a versatile workhorse in device design.

Catheters and Endoscopes

The low-friction surface of PTFE is essential for creating liners for catheters and endoscopes. It allows these instruments to be inserted and maneuvered with minimal force, improving both patient safety and procedural success.

Surgical Instruments and Implants

Because of its biocompatibility, PTFE is used in implants and as a component in surgical instruments. Its inertness ensures long-term reliability without causing inflammation or rejection by the body.

Fluid and Sample Management

In laboratory and diagnostic equipment, PTFE's chemical resistance and purity are paramount. It is used for pump seals, syringe components, and sample transport mechanisms to ensure that there is no contamination and that equipment operates flawlessly.

Understanding the Material Trade-offs

While PTFE is an exceptional material, no choice is without its considerations. Acknowledging its limitations is key to proper application.

Mechanical Strength

Standard, unfilled PTFE is a relatively soft material. It can be susceptible to "creep" or deforming under a sustained load, which makes it unsuitable for high-stress structural applications on its own.

To overcome this, fillers like glass or carbon are often added. This creates "filled PTFE" grades with significantly improved strength and wear resistance for components like bearings or high-load seals.

Processing and Fabrication

PTFE can be more challenging to process than common plastics. It cannot be melt-processed in the same way, often requiring specialized techniques like compression molding and sintering, which can impact manufacturing costs and complexity.

Making the Right Choice for Your Device

Selecting the right material requires aligning its properties with the primary goal of your medical device.

- If your primary focus is direct patient contact (implants, catheters): The unparalleled biocompatibility and low-friction surface of PTFE are its most critical advantages.

- If your primary focus is fluid handling (pumps, valves, seals): The material's extreme chemical inertness ensures purity and device integrity.

- If your primary focus is mechanical components (bearings, cutting tools): Consider a filled grade of PTFE to achieve the necessary strength and wear resistance while retaining its other key benefits.

Ultimately, PTFE's unique profile makes it an enabling material that has been instrumental in advancing the safety and effectiveness of medical technology.

Summary Table:

| Key Property | Medical Device Benefit |

|---|---|

| Biocompatibility & Inertness | Safe for long-term implants; prevents adverse tissue reactions. |

| Chemical Resistance | Withstands bodily fluids, drugs, and sterilization without degrading. |

| Low-Friction Surface | Enables smooth insertion of catheters and precise movement of components. |

| Sterilization Resilience | Maintains integrity through repeated autoclaving and other sterilization cycles. |

Leverage PTFE's unique properties for your next medical device project.

At KINTEK, we specialize in the precision manufacturing of high-purity PTFE components—from custom seals and liners to complex labware—for the semiconductor, medical, and laboratory industries. Whether you need prototypes or high-volume production, our expertise ensures your devices meet the highest standards of safety and performance.

Contact our experts today to discuss how our custom PTFE fabrication can enhance your medical device's reliability and patient safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials