The biocompatibility of Polytetrafluoroethylene (PTFE) is a direct result of its extreme chemical inertness. This stability stems from the powerful atomic bonds between carbon and fluorine that make up its structure. Because PTFE does not react with chemicals or biological fluids, it can be placed in direct contact with human tissue without causing adverse reactions, toxicity, or rejection by the body's immune system.

The core reason for PTFE's biocompatibility is its molecular structure. The exceptionally strong carbon-fluorine bonds create a chemically stable and non-reactive material that the human body effectively ignores, making it a safe and reliable choice for medical applications.

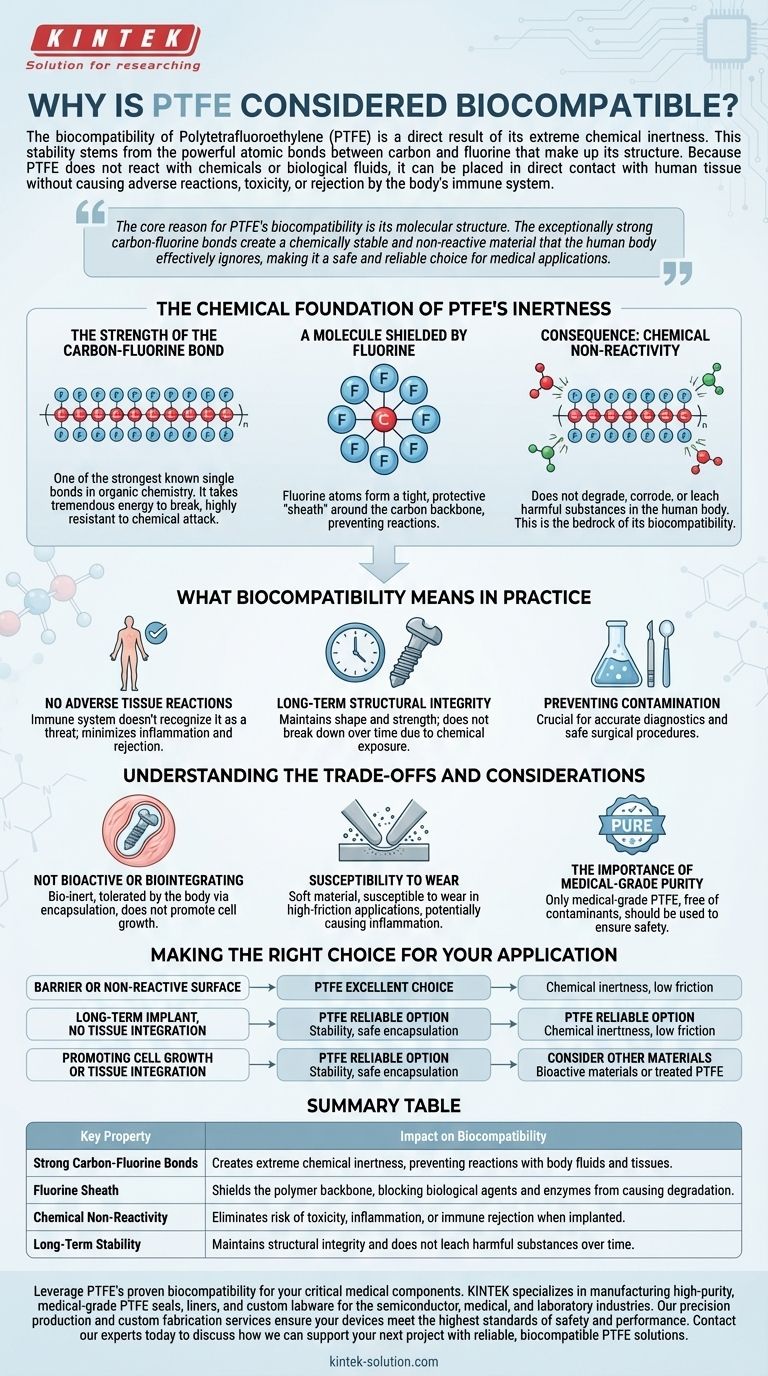

The Chemical Foundation of PTFE's Inertness

To understand why PTFE is so compatible with living tissue, we must first look at its fundamental chemistry. Its properties are not accidental; they are a direct consequence of its unique molecular architecture.

The Strength of the Carbon-Fluorine Bond

The bond between a carbon atom and a fluorine atom is one of the strongest known single bonds in organic chemistry. PTFE is a long polymer chain of a carbon backbone completely surrounded by fluorine atoms.

This immense bond strength means it takes a tremendous amount of energy to break the molecule apart. It is highly resistant to chemical attack from acids, bases, and enzymes found within the body.

A Molecule Shielded by Fluorine

The fluorine atoms are larger than the carbon atoms they are bonded to. They effectively form a tight, protective "sheath" around the vulnerable carbon backbone.

This fluorine sheath prevents other chemicals and biological agents from ever getting close enough to react with the carbon chain, further enhancing its non-reactive nature.

Consequence: Chemical Non-Reactivity

Because of these two factors—strong bonds and molecular shielding—PTFE is one of the most chemically inert substances known.

It does not degrade, corrode, or leach harmful substances when exposed to the complex chemical environment of the human body. This is the bedrock of its biocompatibility.

What Biocompatibility Means in Practice

The chemical inertness of PTFE translates directly into predictable and safe performance when used in medical devices and implants.

No Adverse Tissue Reactions

Since PTFE doesn't react with or release substances into the body, the immune system generally does not recognize it as a foreign threat.

This minimizes the risk of inflammation, allergic reaction, or implant rejection, which is critical for devices that reside within the body for extended periods.

Long-Term Structural Integrity

PTFE's stability ensures that it maintains its physical shape and strength after implantation.

A medical device made from PTFE will not break down or weaken over time due to chemical exposure, ensuring it performs its intended function reliably for the life of the device.

Preventing Contamination

In laboratory or surgical settings, PTFE's inertness is also crucial. Tools or containers made from PTFE will not contaminate biological samples or react with sterilization chemicals.

This purity is essential for accurate diagnostics and safe surgical procedures.

Understanding the Trade-offs and Considerations

While highly biocompatible, PTFE is not the perfect solution for every medical application. Understanding its limitations is key to using it effectively.

Not Bioactive or Biointegrating

Biocompatibility is not the same as bioactivity. PTFE is bio-inert, meaning the body tolerates it by walling it off with a thin layer of fibrous scar tissue.

It does not promote cell growth or actively integrate with surrounding tissue. For applications that require the implant to merge with bone or tissue, other materials or surface modifications are necessary.

Susceptibility to Wear

While chemically robust, PTFE is a relatively soft material. In high-friction applications, such as in joint implants, it can be susceptible to mechanical wear, which may produce particles that can cause an inflammatory response.

The Importance of Medical-Grade Purity

The biocompatibility of a device depends on the purity of the material. Only medical-grade PTFE, which is manufactured under strict controls to be free of contaminants, should be used.

Using an industrial grade of PTFE could introduce impurities that would compromise safety and cause adverse reactions.

Making the Right Choice for Your Application

Ultimately, the decision to use PTFE depends on the specific requirements of your medical device or application.

- If your primary focus is a barrier or non-reactive surface (e.g., catheter liners, grafts): PTFE is an exceptional choice due to its chemical inertness and low friction.

- If your primary focus is a long-term implant that requires no tissue integration: PTFE's stability makes it a reliable option, as it will be safely encapsulated by the body.

- If your primary focus is promoting cell growth or tissue integration: Standard PTFE is unsuitable; you must consider a bioactive material or a PTFE product with specialized surface treatments.

Understanding that PTFE's biocompatibility is rooted in its chemical stability allows you to leverage its strengths with confidence.

Summary Table:

| Key Property | Impact on Biocompatibility |

|---|---|

| Strong Carbon-Fluorine Bonds | Creates extreme chemical inertness, preventing reactions with body fluids and tissues. |

| Fluorine Sheath | Shields the polymer backbone, blocking biological agents and enzymes from causing degradation. |

| Chemical Non-Reactivity | Eliminates risk of toxicity, inflammation, or immune rejection when implanted. |

| Long-Term Stability | Maintains structural integrity and does not leach harmful substances over time. |

Leverage PTFE's proven biocompatibility for your critical medical components. KINTEK specializes in manufacturing high-purity, medical-grade PTFE seals, liners, and custom labware for the semiconductor, medical, and laboratory industries. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure your devices meet the highest standards of safety and performance. Contact our experts today to discuss how we can support your next project with reliable, biocompatible PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs