Teflon is most commonly incorporated into clothing as a protective finish, applied to items like high-performance outerwear, industrial workwear, and everyday apparel to make them resistant to water, stains, and heat. You will find it used in waterproof jackets, firefighter gear, boilersuits, and even on items like leggings, shoes, and belts to enhance their durability and longevity.

The key is to understand that Teflon is not the fabric itself, but rather a high-performance treatment applied to textiles. Its purpose is to create an invisible, protective shield that repels liquids and stains without compromising the fabric's feel or breathability.

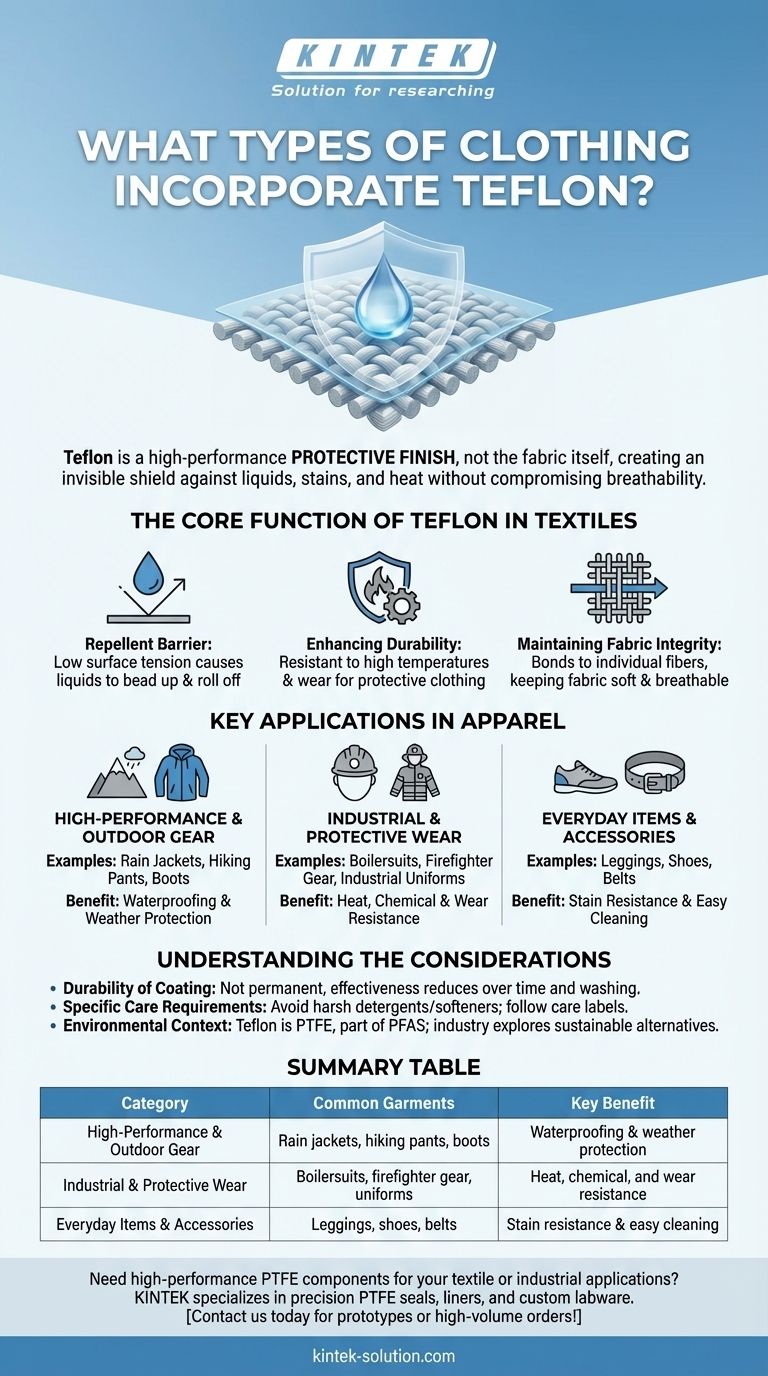

The Core Function of Teflon in Textiles

Teflon's value in the apparel industry comes from its unique chemical properties, which allow it to enhance a fabric's performance significantly. It acts as a shield against the elements and everyday mishaps.

Creating a Repellent Barrier

The primary function of a Teflon fabric protector is to create a surface with very low surface tension. This causes water, oil, and other liquids to bead up and roll off rather than soaking into the fibers. This is the principle behind its exceptional water and stain repellency.

Enhancing Durability and Protection

Beyond stain resistance, Teflon adds a layer of durability. Its resistance to high temperatures and general wear makes it ideal for protective clothing. This is why it is a standard component in gear for firefighters and industrial workers who need protection from heat and liquid spills.

Maintaining Fabric Integrity

A crucial benefit of modern Teflon finishes is that they can be applied without creating a thick, plastic-like coating. The treatment bonds to individual fibers, allowing the fabric to remain soft, lightweight, and breathable. This ensures comfort is not sacrificed for performance.

Key Applications in Apparel

The use of Teflon can be categorized based on the specific performance requirements of the garment. It is found in everything from extreme-weather gear to common accessories.

High-Performance and Outdoor Gear

For outdoor enthusiasts, staying dry is critical. Teflon finishes are applied to rain jackets, hiking pants, and boots to provide a robust waterproof or water-repellent barrier. This keeps the wearer dry from external moisture while often allowing internal moisture (sweat) to escape.

Industrial and Protective Wear

In high-impact environments, clothing must be exceptionally resilient. Boilersuits, firefighter gear, and other forms of industrial uniforms are treated with Teflon to provide resistance against heat, chemicals, and intense wear and tear, ensuring worker safety and extending the life of the garment.

Everyday Items and Accessories

The benefits of Teflon also extend to everyday clothing. It is used on items like leggings, shoes, and belts to resist dirt and stains, keeping them looking new for longer. This application focuses on convenience and maintaining the appearance of the apparel.

Understanding the Considerations

While highly effective, it's important to understand the context and potential trade-offs associated with any fabric treatment, including Teflon.

Durability of the Coating

The Teflon finish is not permanent. Over time, repeated washing, abrasion, and exposure to the elements can gradually reduce its effectiveness. The repellent properties may need to be refreshed with specialized care products.

Specific Care Requirements

Garments treated with a performance finish often require specific care to maintain their function. Using harsh detergents or fabric softeners can clog the protective layer and diminish its ability to repel water and stains. Always follow the manufacturer's care label.

Environmental Context

Teflon is a brand name for PTFE, which belongs to a larger family of chemicals known as PFAS. There are ongoing discussions and evolving regulations regarding the environmental impact of these chemicals. As a result, many brands are actively exploring and shifting toward alternative, more sustainable water-repellent technologies.

Making the Right Choice for Your Goal

When selecting apparel, understanding why a Teflon finish might be included helps you align your purchase with your specific needs.

- If your primary focus is extreme weather protection: Look for Teflon or similar branded finishes on high-end outdoor gear where reliable waterproofing is essential for safety and comfort.

- If your primary focus is workplace safety: Seek out industrial or protective clothing that explicitly lists a protective coating for resistance against heat, oil, and spills.

- If your primary focus is everyday convenience and stain resistance: Consider it a valuable feature on items like work trousers, school uniforms, or upholstery to simplify cleaning and prolong their life.

Ultimately, choosing clothing with a Teflon finish is a decision based on a clear need for enhanced protection, durability, and performance.

Summary Table:

| Category | Common Garments | Key Benefit |

|---|---|---|

| High-Performance & Outdoor Gear | Rain jackets, hiking pants, boots | Waterproofing & weather protection |

| Industrial & Protective Wear | Boilersuits, firefighter gear, uniforms | Heat, chemical, and wear resistance |

| Everyday Items & Accessories | Leggings, shoes, belts | Stain resistance & easy cleaning |

Need high-performance PTFE components for your textile or industrial applications?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for industries like semiconductor, medical, and laboratory. Whether you require prototypes or high-volume orders, our custom fabrication ensures durability and reliability.

Contact us today to discuss how our PTFE solutions can enhance your product performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability