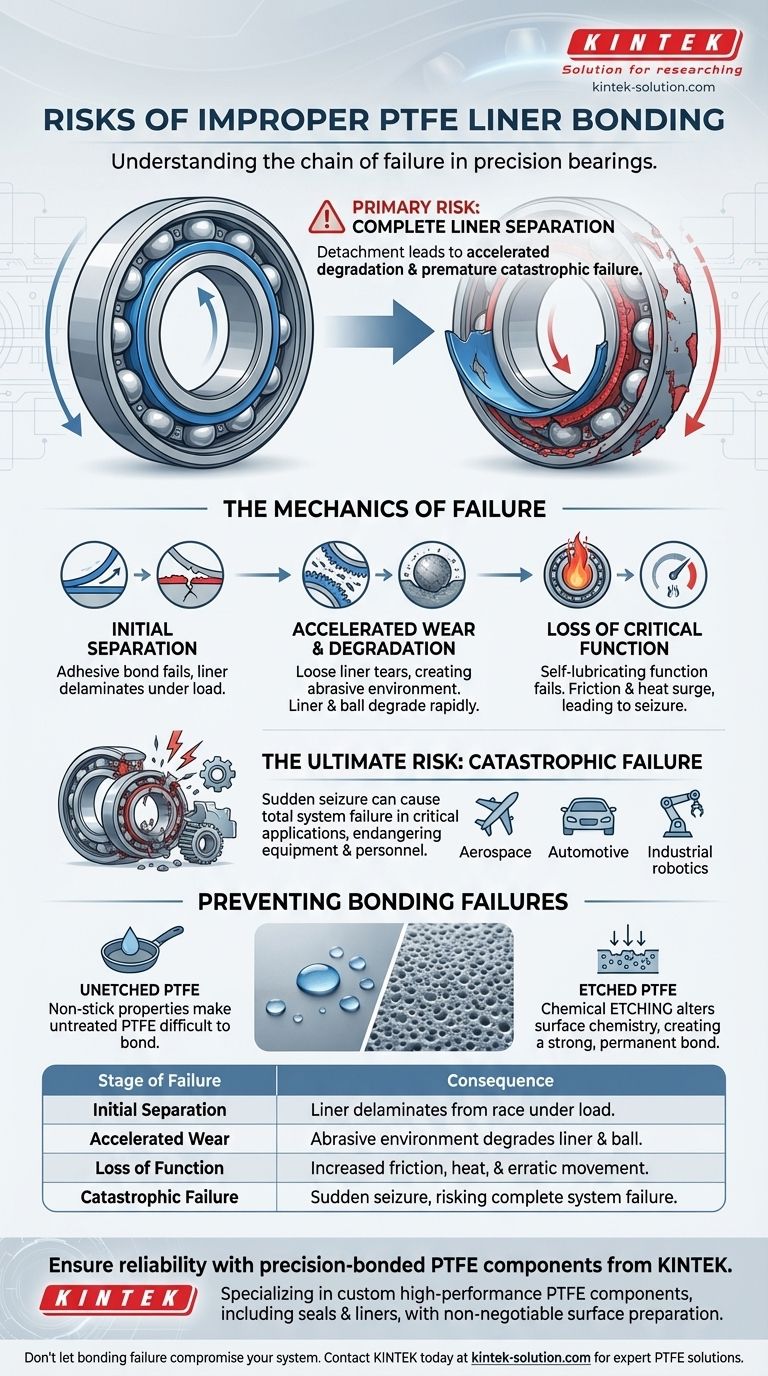

The primary risk of improper PTFE liner bonding is the complete separation of the liner from its housing, known as the race. This detachment leads to accelerated degradation of both the liner and the bearing ball, culminating in premature and often catastrophic failure of the entire bearing assembly.

The adhesive bond is not a secondary detail; it is the fundamental mechanism that ensures the PTFE liner functions as an integrated part of the bearing. When this bond fails, the bearing's integrity is compromised, turning a precision component into a critical and unpredictable point of failure.

The Mechanics of Failure: What Happens When a Bond Fails?

When the bond between a PTFE liner and the bearing race is insufficient, a predictable chain of events begins. This process rapidly moves from a minor defect to a complete functional breakdown.

The Initial Separation

The adhesive bond is the only thing holding the low-friction PTFE liner securely against the outer race. An improper bond allows the liner to delaminate or pull away from this surface under operational loads.

Accelerated Wear and Degradation

Once separated, the liner is no longer a stable, smooth surface. It can bunch up, tear, or shred. This loose material creates an abrasive environment that rapidly degrades not only the liner itself but also the precision-ground surface of the bearing's ball.

Loss of Critical Function

The purpose of the liner is to provide a self-lubricating, low-friction interface. A detached and degrading liner cannot perform this function. The result is a sudden increase in friction, heat, and erratic movement, leading to bearing seizure.

The Ultimate Risk: Catastrophic Component Failure

The consequences of a failed bond extend far beyond the bearing itself. In any system where bearings are used, their failure can have severe and wide-ranging impacts.

From Minor Defect to Total Failure

What begins as a microscopic bonding failure quickly escalates. The bearing's performance degrades, introducing slop and resistance into the system until it fails entirely. This failure is often not gradual but sudden.

The Impact in Critical Applications

In critical systems, such as aerospace controls, automotive steering, or industrial robotics, this type of failure can be catastrophic. The sudden seizure of a rod end or spherical bearing can lead to a complete loss of control or system functionality, endangering equipment and personnel.

Preventing Bonding Failures

Understanding why bonds fail is key to preventing it. The inherent properties of PTFE make it a challenging material to adhere to, which is why surface preparation is non-negotiable.

The Challenge of Bonding PTFE

PTFE is known for its non-stick properties, which makes it an excellent bearing surface but exceptionally difficult for adhesives to grip. Standard, untreated PTFE will not form a reliable bond.

The Critical Role of Etching

To ensure proper adhesion, PTFE liners must be chemically etched on the bonding side. This process alters the surface chemistry of the material, creating a bondable face that allows adhesives to form a strong, permanent connection with the race. Using liners that are not properly etched is the primary cause of bonding failure.

Making the Right Choice for Your Application

Ensuring bond integrity is a matter of material specification and quality control. The focus must be on the liner's preparation before it is ever installed.

- If your primary focus is safety and reliability in critical systems: Mandate the use of properly etched PTFE liners and verify the bonding process, as this is a foundational requirement for preventing catastrophic failure.

- If your primary focus is longevity and performance: Proper bonding is essential for achieving the expected service life of a bearing, directly preventing the premature wear that leads to costly downtime and repairs.

Ultimately, the integrity of the entire mechanical system relies on the quality of a bond measured in thousandths of an inch.

Summary Table:

| Stage of Failure | Consequence |

|---|---|

| Initial Separation | Liner delaminates from the race under load. |

| Accelerated Wear | Liner shreds, creating an abrasive environment that degrades the ball. |

| Loss of Function | Increased friction, heat, and erratic movement, leading to seizure. |

| Catastrophic Failure | Sudden bearing seizure, risking complete system failure in critical applications. |

Ensure the reliability of your critical systems with precision-bonded PTFE components from KINTEK.

A failed PTFE bond is not a minor defect—it's a critical point of failure. For industries like semiconductor, medical, aerospace, and industrial automation where safety and performance are paramount, you need a supplier who masters the complex chemistry of PTFE bonding.

KINTEK specializes in the custom fabrication of high-performance PTFE components, including seals, liners, and labware. We prioritize precision production and understand that proper surface preparation, like etching, is non-negotiable for a permanent, reliable bond. From prototypes to high-volume orders, we ensure every component meets the rigorous demands of your application.

Don't let a bonding failure compromise your system. Contact KINTEK today to discuss your specific requirements and leverage our expertise in PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech