In short, PTFE lip seals excel in high-speed rotary applications because their exceptionally low friction coefficient minimizes the primary cause of seal failure: heat generation. Combined with outstanding thermal stability, this allows them to maintain their integrity and sealing performance at surface speeds where traditional elastomeric seals would rapidly degrade and fail.

The fundamental challenge of any high-speed seal is managing the immense heat generated by friction. PTFE is not just resistant to this heat; its core advantage is that it creates significantly less of it in the first place, ensuring longer life and greater reliability for the entire system.

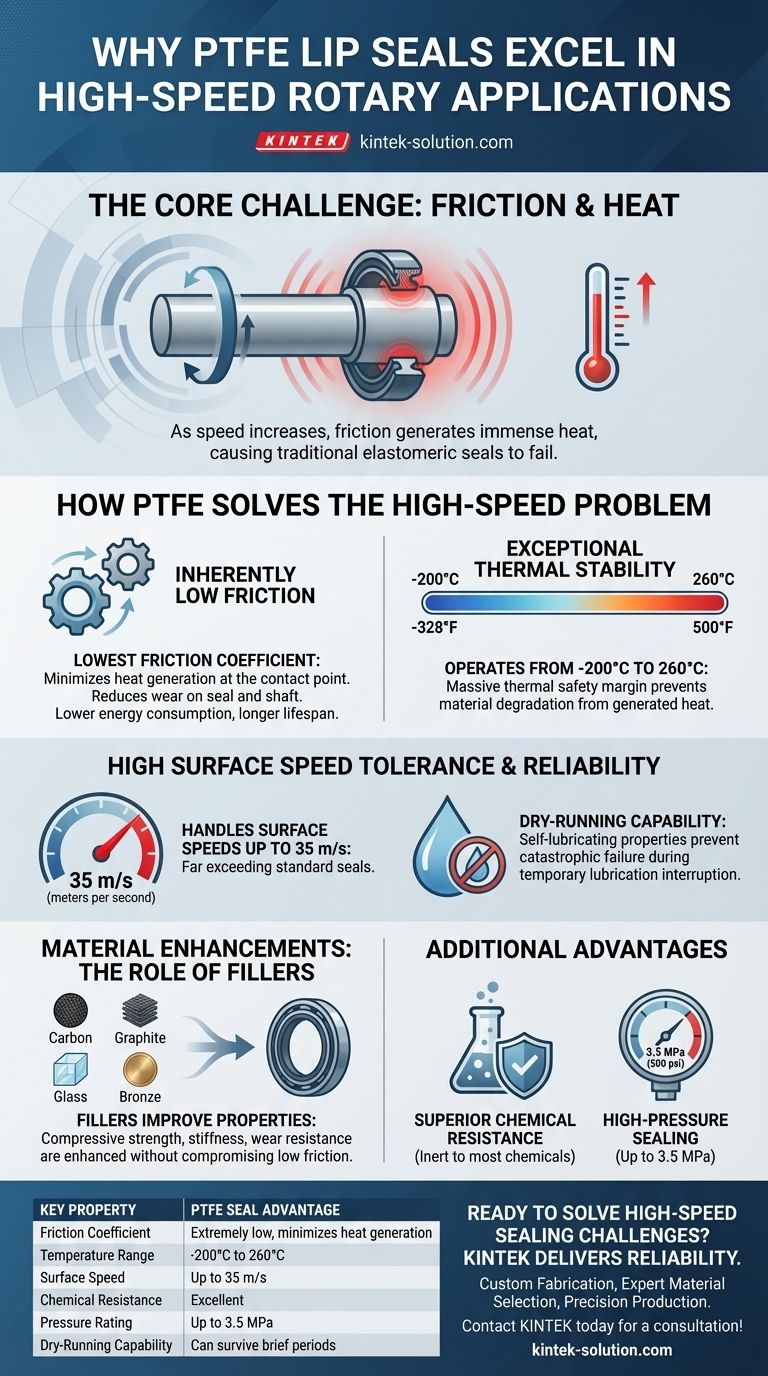

The Core Challenge: Friction and Heat at High Speeds

In any rotary application, the seal lip and the spinning shaft are in constant contact. As rotational speed increases, so does the friction between these two surfaces.

This friction generates heat. For many common seal materials, like elastomers (rubber), this heat accumulation is a critical point of failure. Excessive temperatures can cause the material to harden, crack, or even melt, leading to catastrophic seal failure and leaks.

How PTFE Directly Solves the High-Speed Problem

PTFE (Polytetrafluoroethylene) possesses a unique combination of properties that directly counteracts the challenges posed by high rotational speeds.

Inherently Low Friction

This is the most critical advantage. PTFE has one of the lowest coefficients of friction of any solid material.

This low-friction nature means less heat is generated at the point of contact, even at very high speeds. This directly reduces wear on both the seal and the shaft, leading to lower energy consumption and a much longer operational lifespan.

Exceptional Thermal Stability

PTFE can operate effectively across an incredibly wide temperature range, typically from -200°C (-328°F) to 260°C (500°F).

This provides a massive thermal safety margin. The small amount of heat that is generated by friction is well within the material's tolerance, preventing the degradation that affects other materials.

High Surface Speed Tolerance

Because they generate less heat and resist it better, PTFE seals are rated for much faster applications.

They can reliably handle shaft surface speeds of up to 35 m/s (meters per second), far exceeding the capabilities of most standard elastomeric seals.

Dry-Running Capability

While not recommended for extended periods, PTFE seals can survive brief periods of inadequate lubrication.

Their self-lubricating properties prevent immediate, catastrophic failure if lubrication flow is temporarily interrupted, adding a layer of reliability to the system.

Understanding the Trade-offs and Material Enhancements

While base PTFE is excellent, it is not a perfect material for every scenario. Its performance is often optimized for specific demands.

The Role of Fillers

Pure PTFE can be relatively soft and prone to deformation under load.

To counteract this, fillers such as carbon, graphite, glass, or bronze are blended into the PTFE. These fillers significantly improve key properties like compressive strength, stiffness, and wear resistance without compromising the low-friction nature of the material.

Shaft and Installation Considerations

PTFE is less flexible and elastic than rubber. This means installation can require more care, sometimes using special tools to prevent damage to the seal lip.

Furthermore, to maximize the life of a PTFE seal, the shaft's surface finish and hardness are critical. A smoother, harder shaft surface minimizes abrasion and wear on the seal lip.

Beyond Speed: Additional Performance Advantages

While ideal for high-speed use, other properties make PTFE a robust choice for demanding environments in general.

Superior Chemical Resistance

PTFE is almost completely inert, providing excellent resistance to a wide range of aggressive chemicals, including acids, bases, solvents, and oils.

High-Pressure Sealing

Engineered PTFE seals can effectively seal against pressures up to 3.5 MPa (500 psi), making them suitable for applications that combine both high speed and high pressure.

Making the Right Choice for Your Application

Selecting the right seal requires understanding your primary operational challenge.

- If your primary focus is maximum rotational speed and efficiency: PTFE is the clear choice, as its low friction directly reduces heat buildup and energy loss.

- If your primary focus is reliability in extreme temperatures: PTFE's vast operating range ensures stable performance where conventional elastomers would fail from heat or cold.

- If your primary focus is handling aggressive fluids: PTFE's chemical inertness provides unmatched protection against a wide spectrum of corrosive media.

Ultimately, choosing PTFE is a strategic decision for applications where the combined demands of speed, temperature, and pressure make conventional seals a primary point of failure.

Summary Table:

| Key Property | PTFE Seal Advantage |

|---|---|

| Friction Coefficient | Extremely low, minimizing heat generation |

| Temperature Range | -200°C to 260°C (-328°F to 500°F) |

| Surface Speed | Up to 35 m/s (meters per second) |

| Chemical Resistance | Excellent resistance to acids, bases, solvents |

| Pressure Rating | Up to 3.5 MPa (500 psi) |

| Dry-Running Capability | Can survive brief periods without lubrication |

Ready to Solve Your High-Speed Sealing Challenges?

PTFE lip seals from KINTEK deliver the reliability and performance your demanding applications require. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision-engineered PTFE components—including seals, liners, and labware—are manufactured to withstand extreme conditions.

We offer:

- Custom fabrication from prototypes to high-volume orders

- Expert material selection with optimized fillers (carbon, graphite, glass, bronze) for enhanced wear resistance and strength

- Precision production ensuring consistent quality and long service life

Don't let seal failure compromise your equipment. Let our team help you select or design the perfect PTFE solution for your high-speed, high-temperature, or chemically aggressive environment.

Contact KINTEK today for a consultation and see how our PTFE expertise can benefit your operation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs