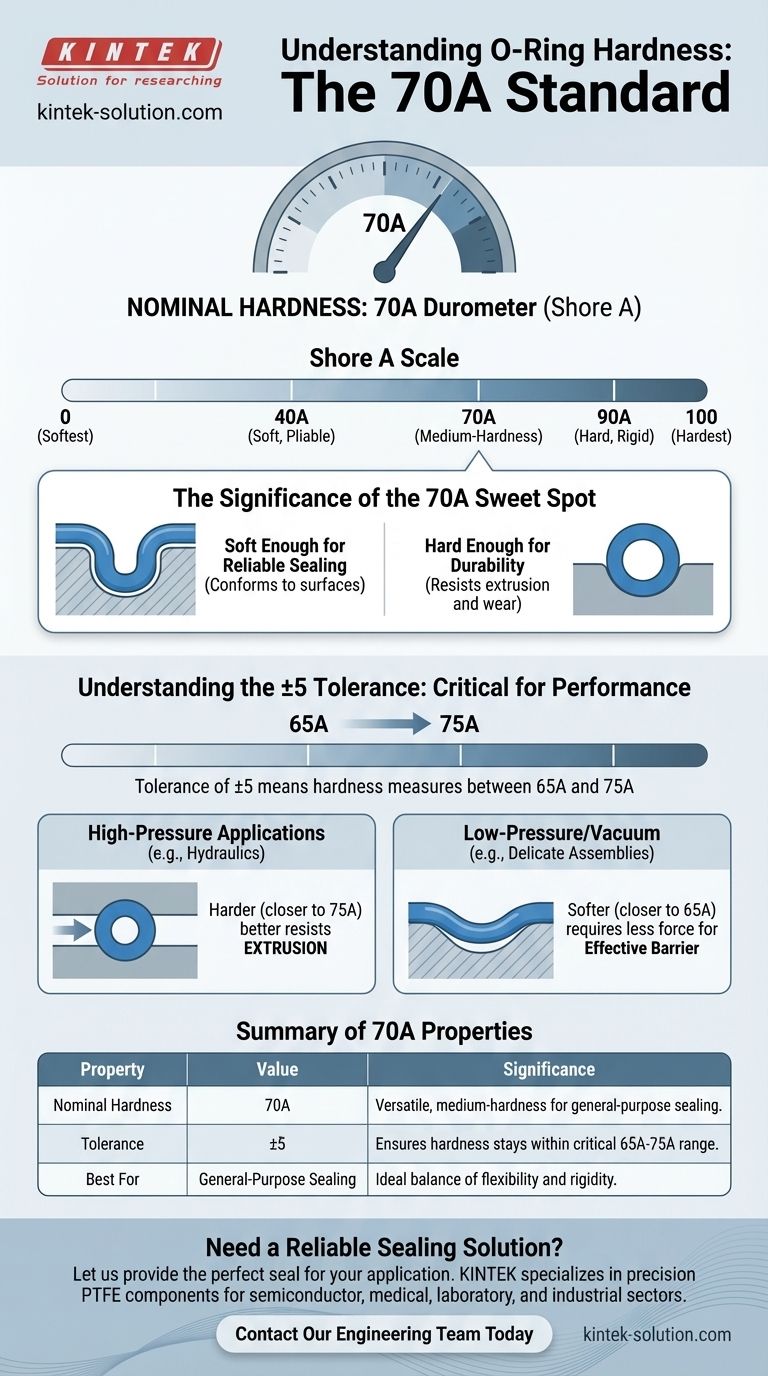

In short, these o-rings have a nominal hardness of 70A durometer. This is a common, medium-hardness rating for general-purpose seals. The specified tolerance of ±5 means any given o-ring will measure between 65A and 75A, a critical detail for consistent sealing performance.

The core issue isn't just the number "70," but understanding what that number, and its tolerance, implies for your application. A 70A durometer represents a balance of flexibility for sealing and rigidity for durability, making it a versatile but not universal solution.

Why "70A" is the Industry Standard

What Durometer Actually Measures

Durometer is the international standard for measuring the hardness of rubber, plastics, and other non-metallic materials. The "A" in 70A refers to the Shore A scale, which is used for flexible, rubber-like materials.

The measurement is taken with a device that presses a standardized cone or indenter into the material's surface. The resistance to that indentation determines the durometer value on a scale from 0 to 100.

A lower number (e.g., 40A) signifies a softer, more pliable material that can easily conform to surface imperfections.

A higher number (e.g., 90A) signifies a harder, more rigid material that offers greater resistance to extrusion and abrasion.

The Significance of the 70A Sweet Spot

The 70A durometer is arguably the most common hardness for o-rings and seals across all industries. This is because it provides an ideal compromise between competing physical properties.

It is soft enough to deform under pressure and create a reliable seal, even on surfaces that aren't perfectly smooth.

At the same time, it is hard enough to resist being squeezed out (extruded) from the sealing groove under moderate pressures and to withstand general wear and tear.

Understanding the Trade-offs: The Importance of ±5

The "±5" tolerance is not a minor detail; it is a fundamental aspect of elastomer manufacturing that directly impacts design and performance.

Why Tolerances Exist

Rubber molding is a less precise process than machining metal. Minor variations in material batches, cure time, and temperature create slight differences in the final hardness of the parts.

A ±5 tolerance is a standard industry benchmark for high-quality o-rings, indicating good process control.

Impact on High-Pressure Applications

For high-pressure systems, the primary risk is extrusion, where the o-ring is forced into the small gap between two metal components. A harder o-ring (closer to 75A) will resist this better than a softer one (closer to 65A).

If your application pushes the pressure limits for a 70A seal, you must design for the worst-case scenario: an o-ring on the softest end of the tolerance range.

Impact on Low-Pressure or Vacuum Sealing

For vacuum or very low-pressure applications, the primary need is for the seal to conform to the groove surfaces with minimal force.

Here, a softer o-ring (closer to 65A) is advantageous. It requires less "squeeze" to create an effective barrier, which is beneficial in delicate assemblies or where surfaces may have minor irregularities.

Making the Right Choice for Your Goal

Understanding the properties of a 70A durometer o-ring allows you to correctly apply it to your specific engineering challenge.

- If your primary focus is general-purpose sealing: A 70A durometer o-ring is the default, reliable choice for a wide range of standard fluid and pneumatic applications.

- If your primary focus is high-pressure resistance: You should verify that your design's extrusion gap is suitable for the lower 65A tolerance, or consider using a harder 90A o-ring with anti-extrusion backup rings.

- If your primary focus is vacuum or low-pressure sealing: A 70A o-ring is often sufficient, but for critical applications, a softer 50A or 60A durometer seal may provide a more reliable result with less compressive force.

Ultimately, selecting the correct seal requires matching the material's properties to the precise demands of your application.

Summary Table:

| Property | Value | Significance |

|---|---|---|

| Nominal Hardness | 70A | A versatile, medium-hardness for general-purpose sealing. |

| Tolerance | ±5 | Ensures hardness stays within a critical 65A to 75A range. |

| Best For | General-purpose sealing | Ideal balance of flexibility for sealing and rigidity for durability. |

Need a Reliable Sealing Solution?

At KINTEK, we understand that the right o-ring is critical to your project's success. Whether you're working in the semiconductor, medical, laboratory, or industrial sector, our expertise in precision PTFE component manufacturing ensures you get the exact specifications you need—from custom prototypes to high-volume production.

Let us provide the perfect seal for your application.

Contact our engineering team today for a consultation on custom PTFE seals, liners, and labware.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance