Under heavy loads, the primary downside of a pure PTFE bushing is its tendency to physically deform. This material, known for its exceptional low-friction properties, is also inherently soft. When subjected to significant, sustained pressure, it can "crawl" or "twist" out of its intended shape, which can compromise the performance and integrity of the entire assembly.

While pure Polytetrafluoroethylene (PTFE) is an exceptional low-friction material, its softness makes it prone to "creep" or deformation under sustained heavy loads. This limitation is almost always addressed in demanding applications by using PTFE composites with fillers, which significantly enhance load-bearing capabilities without sacrificing core benefits.

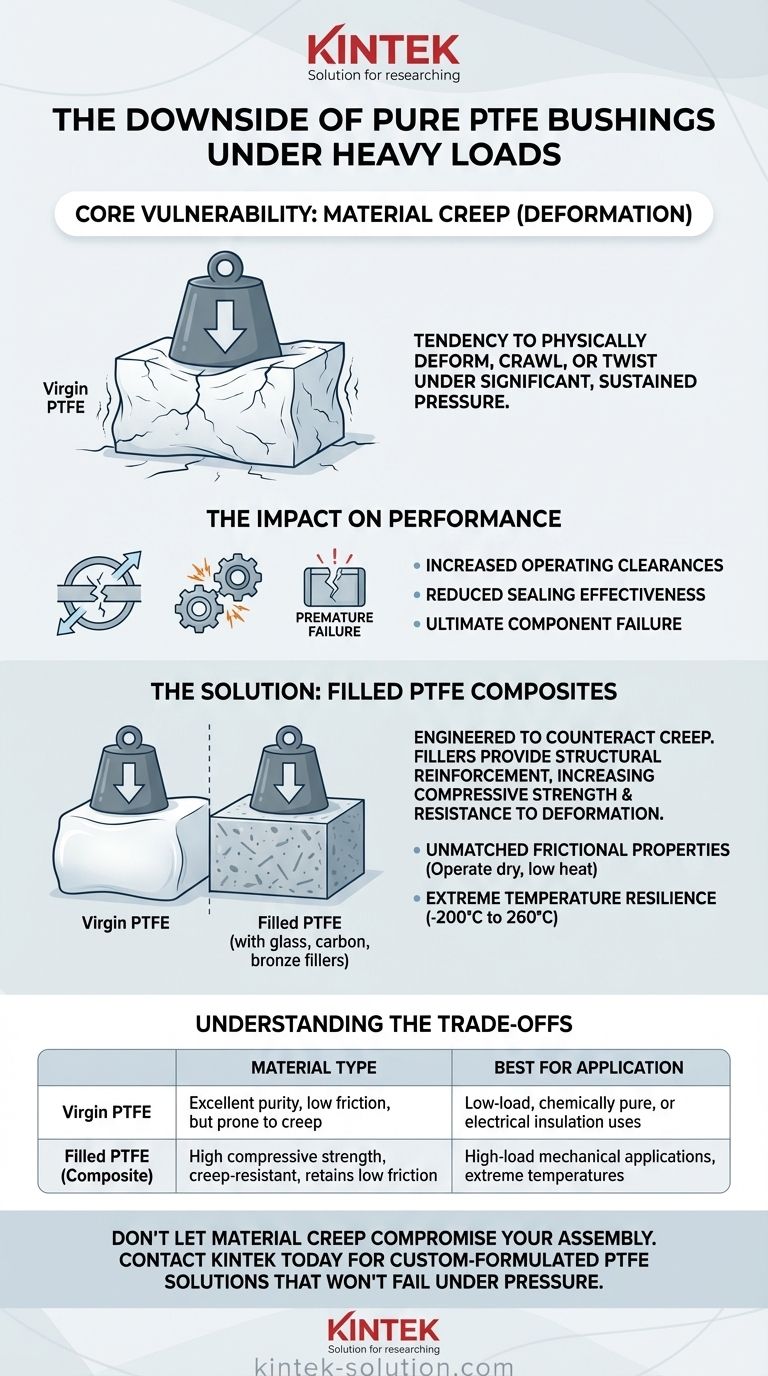

The Core Vulnerability: Material Creep

The flexibility that makes PTFE a great sealant can become a liability under significant mechanical stress. This phenomenon is known as creep or cold flow.

What "Crawling and Twisting" Means

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stresses. For a PTFE bushing under a heavy, constant load, this means the material can gradually flow out of high-pressure areas.

This deformation isn't a sudden failure but a slow process that can result in a loss of dimensional stability, causing the bushing to crawl from its position or twist out of alignment.

The Impact on Performance

This physical deformation is not merely a cosmetic issue. When a bushing deforms, it can increase operating clearances, reduce sealing effectiveness, and ultimately lead to premature failure of the component it is designed to protect.

Why PTFE Is Still Used in High-Load Applications

Given this potential for deformation, the widespread use of PTFE in heavy-duty applications seems contradictory. The solution lies in engineering the material itself.

The Key: Filled PTFE Composites

The issue of creep is most prominent in virgin PTFE. To counteract this, manufacturers add fillers like glass, carbon, or bronze to create a PTFE composite.

These fillers provide structural reinforcement, dramatically increasing the material's compressive strength and resistance to creep. This allows the bushing to handle heavy loads while retaining PTFE's signature benefits.

Unmatched Frictional Properties

Even in its composite form, PTFE offers uniquely low friction. This allows components to operate dry without liquid lubrication, which reduces heat, lowers maintenance costs, and extends the application's service life.

Extreme Temperature Resilience

PTFE performs exceptionally well across a vast temperature range, from cryogenic conditions as low as -200°C (-328°F) up to 260°C (500°F). This makes it a reliable choice for environments where other polymers would fail.

Understanding the Trade-offs

The choice between virgin and filled PTFE is a critical engineering decision based entirely on the application's demands. It is not a question of which is "better," but which is correct for the job.

Virgin PTFE vs. Filled PTFE

Virgin PTFE is best suited for moderate loads or applications where absolute chemical purity and electrical insulation are the primary requirements.

Filled PTFE is the standard for high-load mechanical applications. The added filler material provides the necessary rigidity and wear resistance to prevent the deformation seen in pure PTFE.

A Common Misconception

When technical datasheets for PTFE bushings boast of "high load carrying capacity," they are almost always referring to a filled or composite grade of PTFE. Assuming this capability applies to the pure, virgin material is a common and critical mistake.

Making the Right Choice for Your Application

To select the correct material, you must first define your primary operational challenge.

- If your primary focus is a high-load mechanical application: You must specify a filled PTFE composite to prevent creep and ensure dimensional stability.

- If your primary focus is chemical purity or electrical insulation under lower loads: Virgin PTFE is likely the superior and necessary choice.

- If your primary focus is extreme temperature stability: Both virgin and filled PTFE excel, but the specific load requirements will determine which grade is appropriate.

Understanding the distinction between virgin PTFE and its engineered composites is the key to leveraging its benefits without falling victim to its limitations.

Summary Table:

| Material Type | Key Characteristic | Best For Application |

|---|---|---|

| Virgin PTFE | Excellent chemical purity, low friction, but prone to creep | Low-load, chemically pure, or electrical insulation uses |

| Filled PTFE (Composite) | High compressive strength, creep-resistant, retains low friction | High-load mechanical applications, extreme temperatures |

Don't let material creep compromise your assembly.

At KINTEK, we specialize in manufacturing high-performance PTFE components, including bushings, seals, and liners. Our expertise lies in selecting or custom-formulating the right PTFE composite—filled with materials like glass, carbon, or bronze—to provide the structural strength needed for heavy loads in semiconductor, medical, laboratory, and industrial applications.

We ensure your components maintain dimensional stability and performance, from prototypes to high-volume orders.

Contact our experts today to discuss your specific load requirements and get a solution that won't fail under pressure.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability