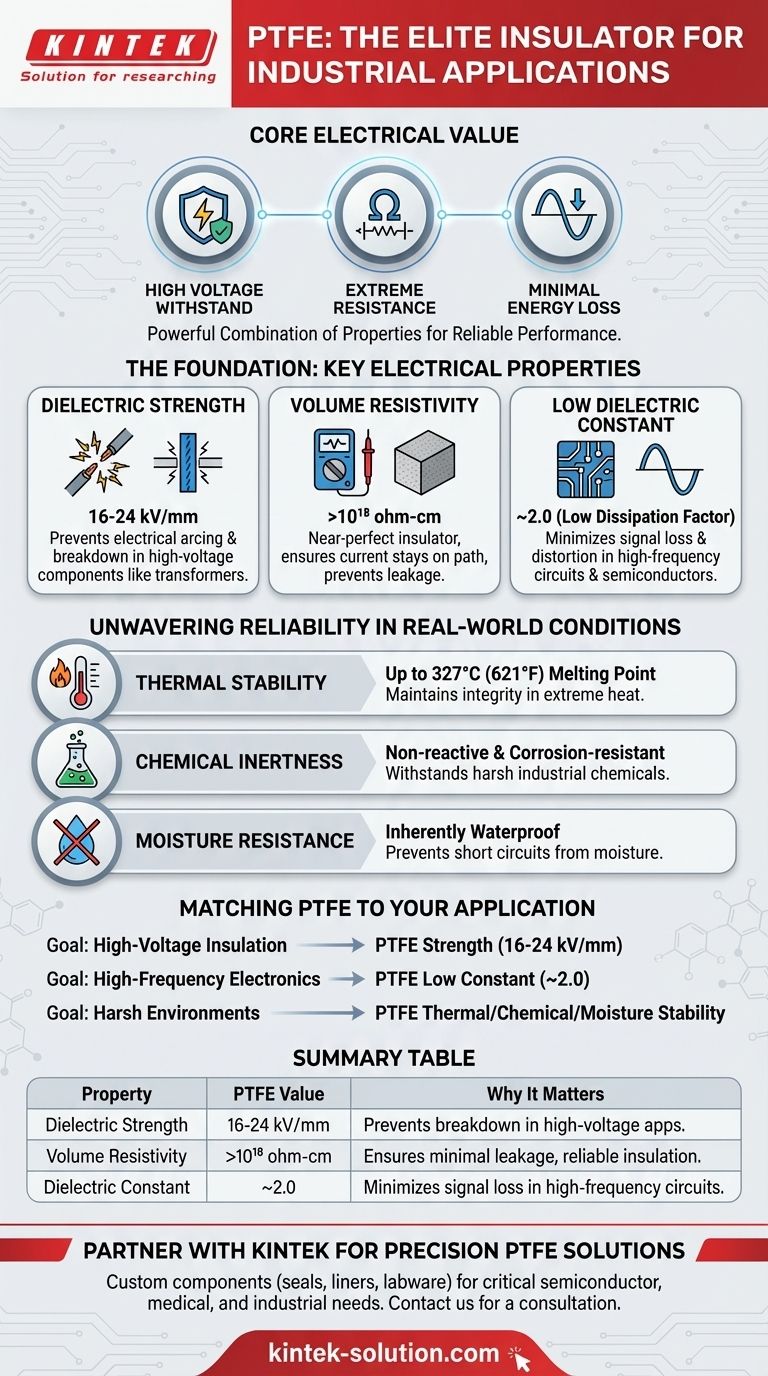

At its core, PTFE’s value in industrial electrical applications comes from a powerful combination of three properties. It possesses an extremely high resistance to the flow of electricity (volume resistivity), an exceptional ability to withstand high voltages without failing (dielectric strength), and minimal energy loss in high-frequency circuits (low dielectric constant).

In demanding industrial settings, an electrical insulator must do more than just block current—it must perform reliably under extreme thermal, chemical, and electrical stress. PTFE excels because its unique molecular structure provides elite insulation that remains stable across wide temperature ranges and high frequencies.

The Foundation: Why PTFE Is an Elite Insulator

PTFE's reputation is built on quantifiable metrics that set it apart from other polymers. These properties are not just abstract numbers; they translate directly into performance and reliability in critical components.

Unpacking High Dielectric Strength

Dielectric strength measures a material's ability to act as an insulator under high voltage. PTFE can withstand 16-24 kilovolts per millimeter (kV/mm) of thickness before breaking down.

This prevents electrical arcing between components, making it an indispensable material for high-voltage wire insulation and transformers where failure is not an option.

Understanding Volume Resistivity

Volume resistivity indicates how strongly a material opposes the flow of electric current through its bulk. PTFE has a volume resistivity greater than 10¹⁸ ohm-cm.

This exceptionally high number signifies that it is a near-perfect insulator, ensuring that electrical current stays precisely where it is intended and does not leak or short-circuit.

The High-Frequency Advantage

PTFE's highly symmetric molecular structure gives it a very low dielectric constant (2.0) and a low dissipation factor.

For high-frequency applications like semiconductors and advanced circuit boards, this is critical. It minimizes signal loss and distortion, ensuring data and power are transmitted with maximum fidelity and efficiency.

Why PTFE's Performance Is So Reliable

An insulator is only as good as its ability to maintain its properties in real-world conditions. PTFE's electrical excellence is supported by its remarkable physical and chemical resilience.

Unwavering Thermal Stability

PTFE maintains its integrity and insulating properties at extreme temperatures, with a high melting point of around 327°C (621°F).

This means critical electrical components can operate in high-heat environments without fear of the insulating material degrading or failing.

Superior Chemical Inertness

PTFE is non-reactive and corrosion-resistant. This chemical inertness ensures that exposure to harsh industrial chemicals will not compromise its physical structure or its electrical insulating capabilities.

Impervious to Moisture

PTFE is inherently waterproof. This quality is crucial for electrical applications, as moisture can create conductive paths, leading to short circuits and insulation failure. PTFE's resistance to water absorption guarantees consistent performance.

Matching PTFE to Your Application

Choosing the right material requires aligning its specific strengths with your primary engineering goal.

- If your primary focus is high-voltage insulation: PTFE's exceptional dielectric strength (16-24 kV/mm) makes it a primary choice for preventing electrical breakdown in wires and transformers.

- If your primary focus is high-frequency electronics: Its low dielectric constant (2.0) ensures maximum signal integrity for components like circuit boards and semiconductors.

- If your primary focus is reliability in harsh environments: Its combination of thermal stability, chemical inertness, and moisture resistance ensures its electrical properties will not degrade over time.

Understanding these core electrical characteristics allows you to leverage PTFE not just as a material, but as a strategic solution for electrical reliability.

Summary Table:

| Key Electrical Property | PTFE Value | Why It Matters |

|---|---|---|

| Dielectric Strength | 16-24 kV/mm | Prevents electrical breakdown in high-voltage applications. |

| Volume Resistivity | >10¹⁸ ohm-cm | Ensures minimal current leakage and reliable insulation. |

| Dielectric Constant | ~2.0 | Minimizes signal loss in high-frequency circuits. |

Need a reliable insulator for your critical components?

PTFE's elite electrical properties—high dielectric strength, extreme volume resistivity, and low dielectric constant—are essential for semiconductor, medical, laboratory, and industrial applications where failure is not an option. At KINTEK, we specialize in manufacturing precision PTFE components (seals, liners, labware, and more) that deliver unmatched performance in harsh environments.

Our custom fabrication services, from prototypes to high-volume orders, ensure you get the exact solution for your high-voltage or high-frequency needs. Let's discuss how our PTFE expertise can enhance your product's reliability—contact us today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments