For device manufacturers, ePTFE membranes and laminates provide a uniquely powerful combination of protection and performance enhancement. They function as a consistent and reliable barrier against microbes and particulate matter while being compatible with a wide range of temperatures and chemicals. This allows for the creation of more durable, dependable, and well-designed devices.

The core value of ePTFE lies in its ability to solve a fundamental engineering paradox: how to allow air to pass through for essential functions like venting while simultaneously blocking the ingress of liquids and harmful contaminants. This dual-capability enhances most device designs by improving both reliability and functionality.

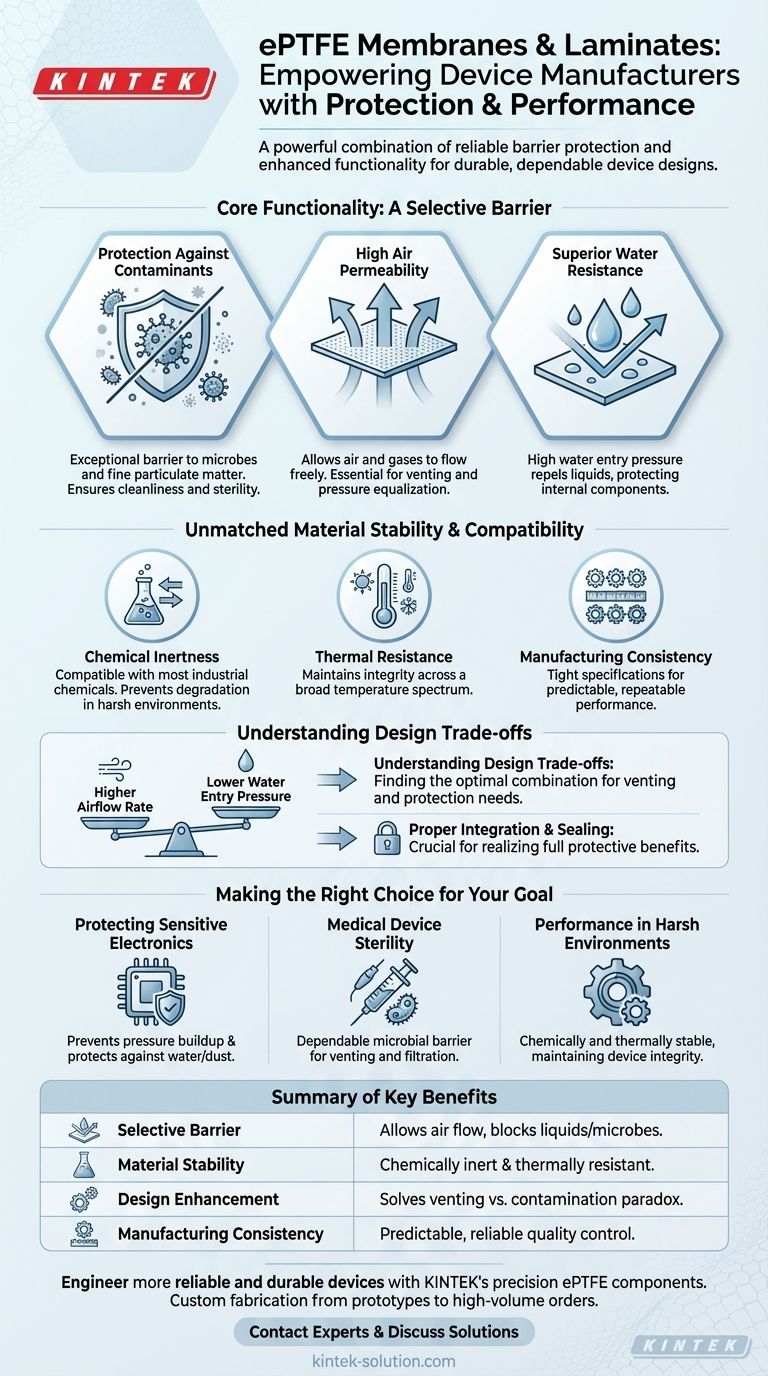

The Core Functionality: A Selective Barrier

The primary benefit of ePTFE comes from its microporous structure, which allows it to act as a highly selective gatekeeper. This structure dictates what can and cannot pass through the membrane.

Protection Against Contaminants

ePTFE serves as an exceptional physical barrier to microbes and fine particulate matter. This is critical for applications where cleanliness, sterility, or the protection of sensitive internal components is paramount.

High Air Permeability

The interconnected pores within the ePTFE structure allow air and other gases to flow through easily. This property is essential for devices that require pressure equalization, venting of off-gassing, or any task requiring controlled airflow.

Superior Water Resistance

Despite being air-permeable, the material exhibits high water entry pressure. This means it effectively repels water and other liquids, preventing them from penetrating the barrier and damaging the device's internal workings.

Unmatched Material Stability and Compatibility

A device is only as strong as its weakest component. ePTFE's inherent stability ensures it can perform its function reliably across a wide range of demanding conditions.

Chemical Inertness

ePTFE is chemically compatible with most industrial chemicals and fluids. This inertness ensures that the membrane will not degrade or fail when exposed to harsh substances, extending the life and reliability of the end device.

Thermal Resistance

The material maintains its structural integrity and performance characteristics across a broad spectrum of temperatures. This thermal stability makes it suitable for devices that operate in extreme heat or cold.

Manufacturing Consistency

For device manufacturers, consistency is key to quality control. ePTFE membranes and laminates are produced to tight specifications, ensuring that barrier and flow properties are predictable and repeatable from one unit to the next.

Understanding the Design Trade-offs

While ePTFE is a high-performance material, its effective implementation requires a clear understanding of its core properties. The key is not just using the material, but using it correctly for the application.

The Airflow vs. Water Pressure Balance

The most critical design consideration is the relationship between airflow and water entry pressure. Generally, a membrane with a higher airflow rate will have a lower water entry pressure, and vice versa. Manufacturers must choose the optimal combination that meets the specific venting and protection needs of their device.

Proper Integration and Sealing

The full benefit of an ePTFE barrier is only realized if it is properly integrated and sealed into the device assembly. Any gaps or improper seals can create a path for contaminants to bypass the membrane, negating its protective qualities.

Making the Right Choice for Your Goal

To determine how ePTFE can best serve your design, consider the primary challenge you need to solve.

- If your primary focus is protecting sensitive electronics: ePTFE provides essential venting to prevent pressure buildup from heat, while offering robust protection against water and dust ingress.

- If your primary focus is medical device sterility: The material acts as a dependable microbial barrier for venting ports and filtration systems, crucial for maintaining a sterile fluid path.

- If your primary focus is performance in harsh environments: Its chemical and thermal stability ensures the membrane will not degrade, maintaining device integrity and function over time.

Ultimately, leveraging ePTFE allows you to engineer more reliable, durable, and functional devices by solving critical environmental and operational challenges at the material level.

Summary Table:

| Key Benefit | Description |

|---|---|

| Selective Barrier | Allows air flow while blocking liquids, microbes, and particulates. |

| Material Stability | Chemically inert and thermally resistant for harsh environments. |

| Design Enhancement | Solves the core paradox of venting versus contamination protection. |

| Manufacturing Consistency | Predictable performance and reliable quality control. |

Engineer more reliable and durable devices with KINTEK's precision ePTFE components.

As a leading manufacturer of high-performance PTFE seals, liners, labware, and custom components, KINTEK specializes in providing device manufacturers in the semiconductor, medical, laboratory, and industrial sectors with the exact ePTFE solutions they need. We offer custom fabrication from prototypes to high-volume orders, ensuring your devices achieve optimal performance and protection.

Contact our experts today to discuss how our ePTFE membranes and laminates can solve your specific design challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry