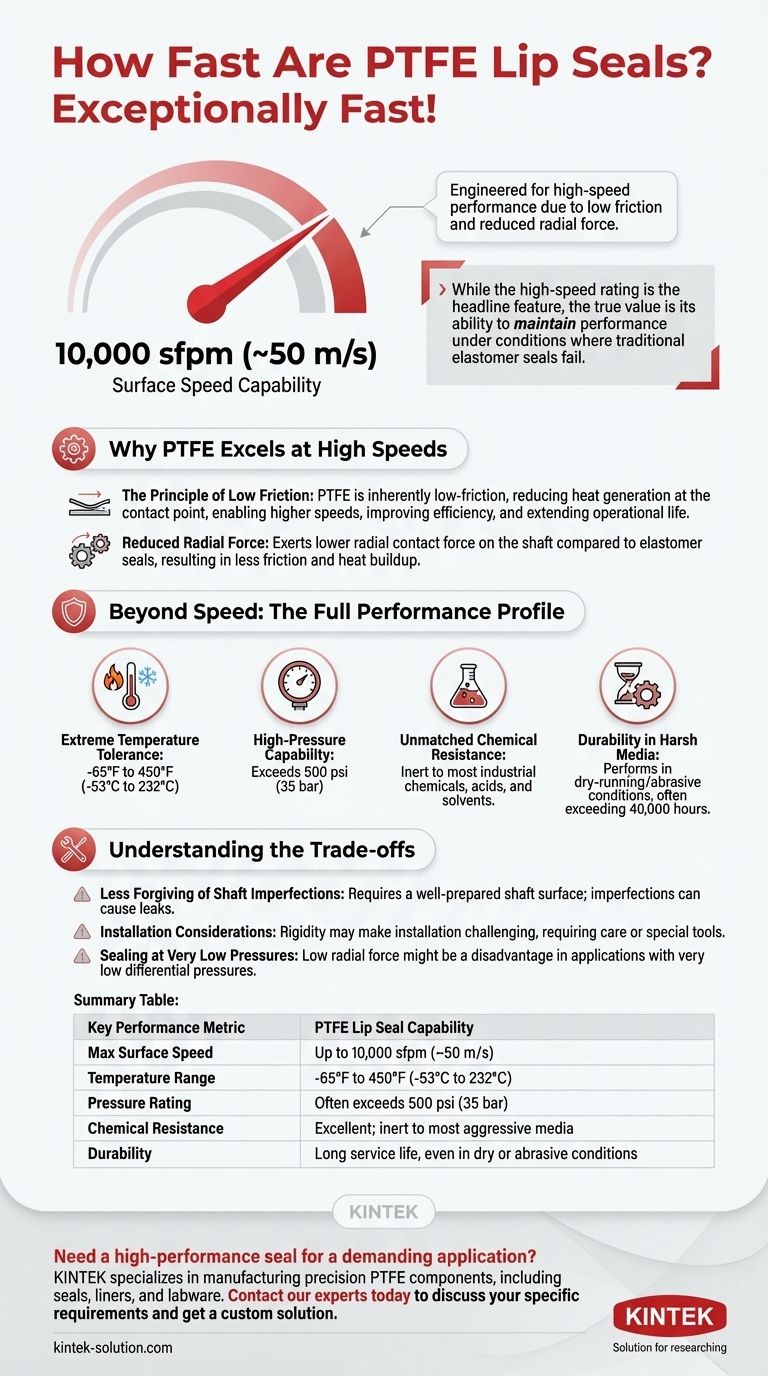

In short, PTFE lip seals are exceptionally fast. They are engineered to operate reliably at surface speeds up to 10,000 surface feet per minute (sfpm), which is approximately 50 meters per second. This high-speed capability is a direct result of the material's unique low-friction properties and the seal's specific design, which exerts less force on the rotating shaft.

While the high-speed rating is the headline feature, the true value of a PTFE lip seal is its ability to maintain that performance under conditions that would cause traditional elastomer seals to fail. It is the combination of speed, temperature tolerance, and chemical resistance that defines its role in demanding applications.

Why PTFE Excels at High Speeds

The ability of a seal to handle high rotational speeds is fundamentally a problem of heat management. Friction between the seal lip and the rotating shaft generates heat, and excessive heat leads to material degradation and premature failure. PTFE seals are engineered to minimize this friction.

The Principle of Low Friction

Polytetrafluoroethylene (PTFE) is an inherently low-friction material. This property reduces the amount of heat generated at the contact point, even at very high surface speeds.

This reduction in friction not only allows for higher speeds but also improves efficiency by minimizing energy loss and extends the operational life of both the seal and the shaft.

Reduced Radial Force

Unlike conventional elastomer seals that rely on high interference (or "squeeze") to create a seal, PTFE lip seals are designed to exert a much lower radial contact force on the shaft.

This lighter touch directly translates to less friction and, therefore, less heat buildup. It is this combination of a low-friction material and a low-force design that unlocks its superior speed capabilities.

Beyond Speed: The Full Performance Profile

Choosing a PTFE seal is rarely a decision based on speed alone. Its suitability comes from a robust set of characteristics that allow it to thrive in extreme operating environments.

Extreme Temperature Tolerance

PTFE seals operate effectively across a vast temperature range, typically from -65°F to 450°F (-53°C to 232°C). This makes them ideal for applications involving cryogenic fluids or high-temperature machinery like turbochargers and compressors.

High-Pressure Capability

These seals are designed to handle significant pressures, often in excess of 500 psi (35 bar). This allows them to be used in demanding hydraulic and pneumatic systems where standard seals would be extruded or destroyed.

Unmatched Chemical Resistance

PTFE is virtually inert to most industrial chemicals, acids, and solvents. This makes it a critical component in chemical processing, pharmaceutical, and semiconductor manufacturing where seals are exposed to aggressive media.

Durability in Harsh Media

A key advantage of PTFE is its ability to perform in dry-running or abrasive media environments. Where traditional seals require lubrication to survive, a PTFE seal can provide a long, maintenance-free service life, sometimes exceeding 40,000 hours.

Understanding the Trade-offs

No engineering solution is without its compromises. The properties that make PTFE seals excel in extreme conditions also introduce specific design and installation considerations.

Less Forgiving of Shaft Imperfections

Because PTFE is a harder, less compliant material than rubber, it requires a well-prepared shaft surface for optimal sealing. Any significant scratches, runout, or surface imperfections on the shaft can create a potential leak path.

Installation Considerations

The rigidity of PTFE can make installation more challenging than with flexible elastomer seals. Special care or specific installation tools may be required to avoid damaging the precision-engineered seal lip.

Sealing at Very Low Pressures

The low radial force that enables high speeds can be a disadvantage in applications requiring a tight seal against gases at very low differential pressures. In these cases, a higher-contact-force elastomer seal might perform better, provided other conditions permit it.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's capabilities to the demands of the operating environment.

- If your primary focus is extreme rotational speed: PTFE is a premier choice, capable of speeds that far exceed the limits of most elastomers, provided the shaft hardware is in excellent condition.

- If you are dealing with aggressive chemicals or extreme temperatures: PTFE's material properties often make it the only viable option, where its performance justifies the additional cost and installation care.

- If your application has standard operating conditions and is cost-sensitive: A traditional elastomer seal is likely the more practical and economical solution.

Ultimately, choosing a PTFE lip seal is a decision to prioritize performance and reliability in environments where other materials simply cannot survive.

Summary Table:

| Key Performance Metric | PTFE Lip Seal Capability |

|---|---|

| Max Surface Speed | Up to 10,000 sfpm (~50 m/s) |

| Temperature Range | -65°F to 450°F (-53°C to 232°C) |

| Pressure Rating | Often exceeds 500 psi (35 bar) |

| Chemical Resistance | Excellent; inert to most aggressive media |

| Durability | Long service life, even in dry or abrasive conditions |

Need a high-performance seal for a demanding application?

KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution engineered for reliability, speed, and longevity.

Contact our experts today to discuss your specific requirements and get a custom solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers