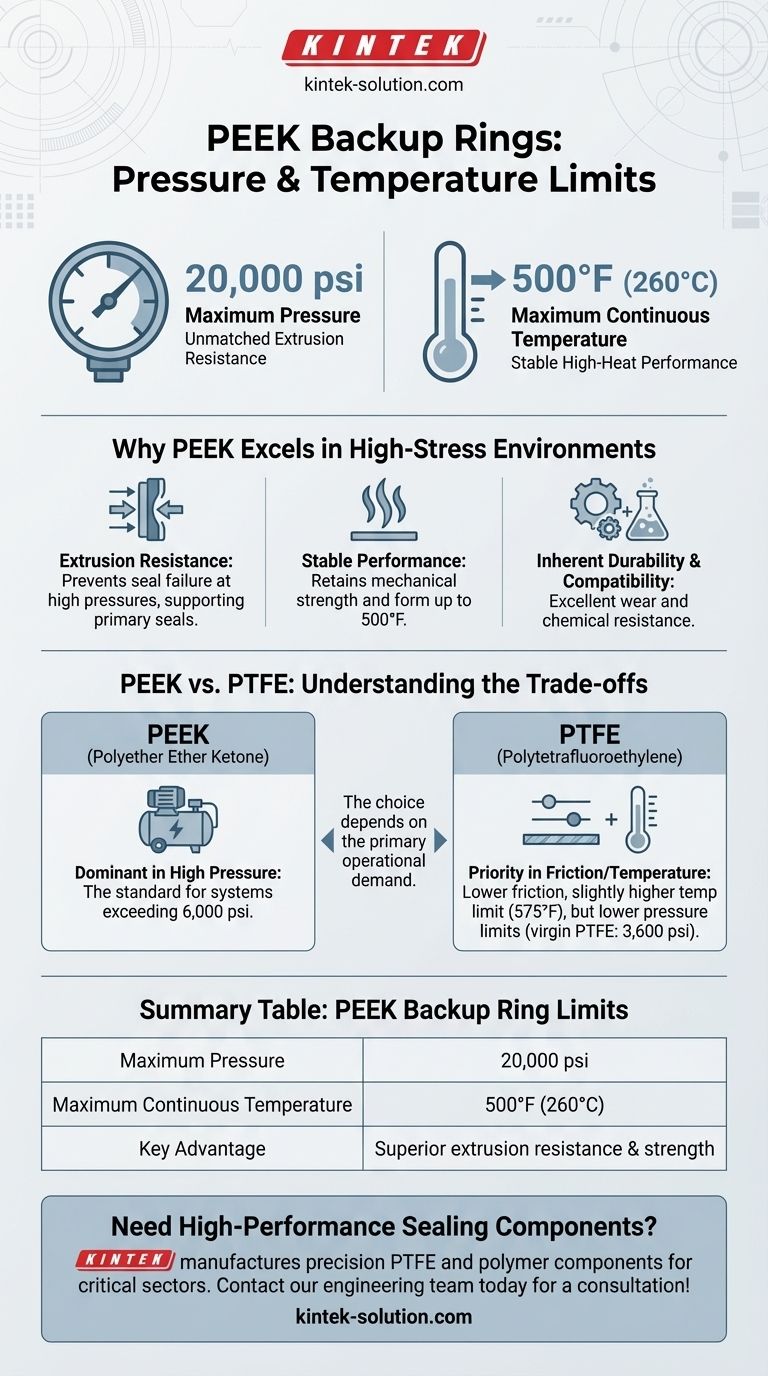

At its operational limits, a PEEK (Polyether Ether Ketone) backup ring can withstand pressures up to 20,000 psi and a maximum continuous temperature of 500°F (260°C). These ratings make it a premier choice for the most demanding sealing applications, where it provides critical support to softer seals like O-rings.

PEEK is not just a material choice; it's a solution for preventing seal failure in extreme conditions. Its primary function as a backup ring is to provide superior extrusion resistance for a primary seal in applications where high pressure would otherwise destroy softer materials.

Why PEEK Excels in High-Stress Environments

The value of PEEK is rooted in its inherent mechanical properties, which remain stable even when subjected to intense pressure and heat simultaneously.

Unmatched Extrusion Resistance

A backup ring's primary job is to prevent the main O-ring from being forced into the small gap between hardware components, a failure known as extrusion.

PEEK's exceptional strength and rigidity make it highly resistant to this phenomenon, allowing it to support the primary seal effectively at pressures reaching 20,000 psi.

Stable Performance at High Temperatures

Many materials lose their structural integrity as temperatures rise. PEEK, however, retains its high mechanical strength up to its 500°F limit.

This thermal stability ensures the backup ring will not soften or deform, which is critical in aerospace, automotive, and high-temperature chemical processing applications.

Inherent Durability and Compatibility

Beyond its core pressure and temperature ratings, PEEK offers excellent wear resistance and chemical compatibility.

This makes it suitable for long-term, high-intensity use in hydraulic systems and aggressive chemical environments where other materials might degrade over time.

Understanding the Trade-offs: PEEK vs. PTFE

While PEEK is a top performer, it's essential to compare it with another common high-performance material, PTFE (Polytetrafluoroethylene), to understand the full context.

When Pressure is the Dominant Factor

PEEK is the definitive choice for high-pressure systems.

Its 20,000 psi rating vastly exceeds that of even filled PTFE backup rings (up to 5,800 psi) and virgin PTFE (around 3,600 psi). If your application pressure exceeds 6,000 psi, PEEK is the standard.

When Temperature or Friction is the Priority

PTFE holds a slight advantage in maximum operating temperature, rated up to approximately 575°F.

Additionally, PTFE is known for its extremely low coefficient of friction, which can be a deciding factor in certain dynamic sealing applications where minimizing drag is paramount.

The Performance-Application Fit

The choice is rarely about which material is "better" in a vacuum, but which is correct for the specific operational demands.

PEEK is engineered for applications where high pressure is the primary challenge, often in combination with high heat. PTFE excels in low-pressure, high-temperature scenarios or where friction is the key concern.

Making the Right Choice for Your Application

Use these guidelines to select the appropriate material for your specific engineering goal.

- If your primary focus is extreme pressure handling (>6,000 psi): PEEK is the only reliable choice due to its superior strength and extrusion resistance.

- If your primary focus is moderate pressure with high temperatures (<5,800 psi): A filled PTFE backup ring offers a capable and often more cost-effective solution.

- If your primary focus is chemical inertness and ultra-low friction at lower pressures: PTFE is typically the preferred material for its unique surface properties.

Ultimately, selecting the right backup ring is about matching the material's core strengths to the specific demands of your sealing system.

Summary Table:

| Property | PEEK Backup Ring Limit |

|---|---|

| Maximum Pressure | 20,000 psi |

| Maximum Continuous Temperature | 500°F (260°C) |

| Key Advantage | Superior extrusion resistance & strength |

Need High-Performance Sealing Components?

When your application demands the extreme pressure and temperature resistance of PEEK, or the unique benefits of PTFE, you need a supplier you can trust.

KINTEK manufactures precision PTFE and high-performance polymer components—including seals, liners, labware, and custom backup rings—for the semiconductor, medical, laboratory, and industrial sectors.

We deliver the precision and durability your critical applications require, from custom prototypes to high-volume production.

Let us help you solve your toughest sealing challenges. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech